The 15 Axis CNC Panel Bending machine Sheet Metal Servo Bending Machine is a state-of-the-art machine designed to provide high-precision and efficient sheet metal bending. The machine is equipped with advanced technology and features 15 CNC-controlled axes, which ensures accurate and efficient bending of sheet metal.

The servo-driven bending system of the machine is capable of bending sheet metal up to 8mm thickness, making it an ideal solution for a wide range of sheet metal bending applications. The machine is also equipped with a high-precision back gauge system that ensures consistent bending accuracy.

The 15 Axis CNC Panel Bending machine Sheet Metal Servo Bending Machine is also highly versatile. It can be used to bend a wide range of sheet metal materials, including steel, aluminum, and copper. This makes it an ideal solution for businesses that work with a variety of different sheet metal materials.

One of the key benefits of the machine is its speed and efficiency. The machine is capable of bending sheet metal at high speeds, which ensures fast and efficient production runs. This makes it an ideal solution for businesses that need to produce large quantities of sheet metal products quickly.

Another benefit of the machine is its ease of use. The machine is equipped with a user-friendly interface that allows operators to easily program and control the machine. This ensures that the machine can be operated by a wide range of operators, without the need for extensive training.

In addition to its advanced technology and features, the 15 Axis CNC Panel Bending machine Sheet Metal Servo Bending Machine is also highly reliable. It is designed to be durable and long-lasting, which means that it can be used for years without needing to be replaced.

In conclusion, the 15 Axis CNC Panel Bending machine Sheet Metal Servo Bending Machine is a highly advanced and efficient machine that is ideal for businesses that need to bend sheet metal quickly and accurately. It is versatile, efficient, and reliable, making it an ideal investment for businesses that are looking for a long-term solution for their sheet metal bending needs.

Quick Description

- Slider Stroke (mm): 1800 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 175 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 2500

- Width of Working Table (mm): 1250 mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum, Plastic, PVC

- Automation: Automatic

- Weight (KG): 8000

- Motor Power (kw): 45 kw

- Key Selling Points: High-accuracy

- Warranty: 1 Year

- Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Advertising Company

- Showroom Location: Egypt, United Kingdom, Viet Nam, India, Mexico, Thailand, Sri Lanka, Malaysia

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 24 months

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox

- Power: CNC

- Name: Panel Bending Machine

- Number of axes: 11/12 optional

- Model: DA52S

- Application: for press brake

- Bending angle: 0-180°

- Dimension: 3370*1890*2650

- Minimum arc radius: 1.2mm

- The fastest continuoue bending speed: 0.5s

- Type: CNC Hydraulic

More Details

Product Description

The intelligent flexible bending center focuses on solving various complex sheet metal bending problems in metal forming. Mainly engaged in the research and development, production and sales of intelligent flexible bending centers, self-propelled robotic arms, multi-axis concurrent linkage control systems, and cloud operation and maintenance management platforms.

RAYMAX have independent intellectual property rights, and realize the real 9-axis concurrent linkage. Each single control board supports 32-axis concurrent linkage, which can realize infinite cascade. Products have been widely used in file cabinets, electrical cabinets, kitchen utensils, fixtures, decoration, ventilation, refrigeration, elevators, car industry, door industry and other metal forming fields.

Compared with traditional hydraulic bending advantages:

1. The processing speed is fast, up to 0.2 seconds/knife;

2. High precision, can reach 0.1mm-0.2mm, the machine is equipped with 15 axes as standard, realizing full automation of complex workpieces.

3. The machine is easy to operate, and one worker can operate multiple devices.

4. The bed is made of castings, with good stability and mature technology, and the machine can be used for a long time to ensure high precision.

Casting!

Casting machine structure and machine body, which ensures machine stable and no shape change for long years use. machine with heat treatment!

Main function configuration:

High-grade casting

9-axis concurrent linkage control system

C axis lift (sucker type)

Double C-axis automatic following system (press arm type)

Graphic visualization error detection programming

Oil supply self-lubricating system

Double Y-U automatic positioning ruler (press arm type)

Workpiece anti-misplacement detection function (press arm type)

Custom function of workpiece precision surface

0.001mm system accuracy

Eccentric load detection system

Plate thickness detection system

Eccentric load bending follow system

Interchangeable and customized narrow module (sucker type)

Cloud operation and maintenance management interface

Y-axis double leaning ruler (sucker type)

Offline editing function

Big data self-learning function

Advanced programming functions

High-speed control module

Up and down pressing dead edge function

Flattening function

Self-driven loading and unloading integrated automation components

Handwheel function

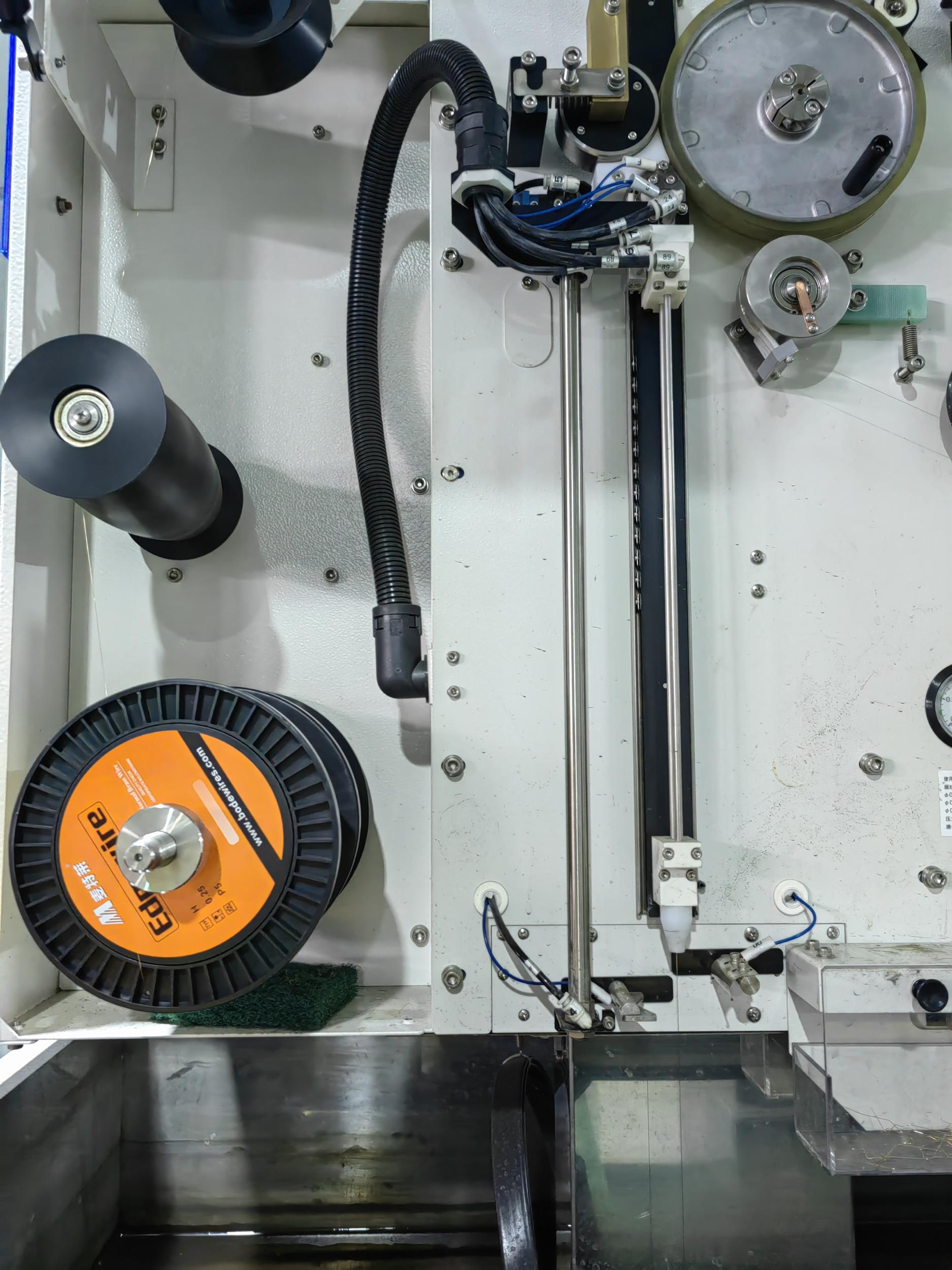

RAYMAX patented tooling die

RAYMAX patented tooling die

RAYMAX patented design of the tooling die, which is friendly to stainless steel. there will be no trace left on the plate surface, to ensure the perfect bending effect.

The upper and lower bending Tool (A, D) perform upward or downward bending during work.

The upper pressing tool (B) works simultaneously with the bending tool and the lower pressing tool

Precise and efficient fixing and bending of sheets.

The lower pressing tool (C) clamps the sheet during bending.

Imported slow wire technology, higher consistency, the precision of the general segment upper pressing tool can reach 0.006mm, to achieve real bending without indentation, the overall heat treatment and ultra-cryogenic process have higher hardness and wear resistance.

Using cr12mov or 42crmo material, different materials can be selected according to customer process.

Self-built tool factory, each tool can be traced back to the source, and passed strict quality inspection, the quality is more guaranteed.

Full automatic type CNC robot

To match with CNC robot arm, realize the full automatic plate loading and work piece unloading. The ensure the most effective and save labor cost !

Automatic loading and unloading technology solution:

The system reserves abundant industry 4.0 .

The interface can be connected to the robot arm to realize automatic loading and unloading.

Equipped with RAYMAX self-propelled robotic arm, it has the same control system as the bending center. There is no need for secondary programming to replace workpieces. The system automatically generates robotic arm movements according to the bending instructions, with higher efficiency and better coordination.