Quick Description

- Application: LASER CUTTING

- Applicable Material: Metal

- Condition: New

- Laser Type: Fiber Laser

- Cutting Area: 1500*3000mm/1500*4000mm/2000*6000mm

- Cutting Speed: 80m/min

- Graphic Format Supported: AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

- Cutting Thickness: 0.3-30

- CNC or Not: Yes

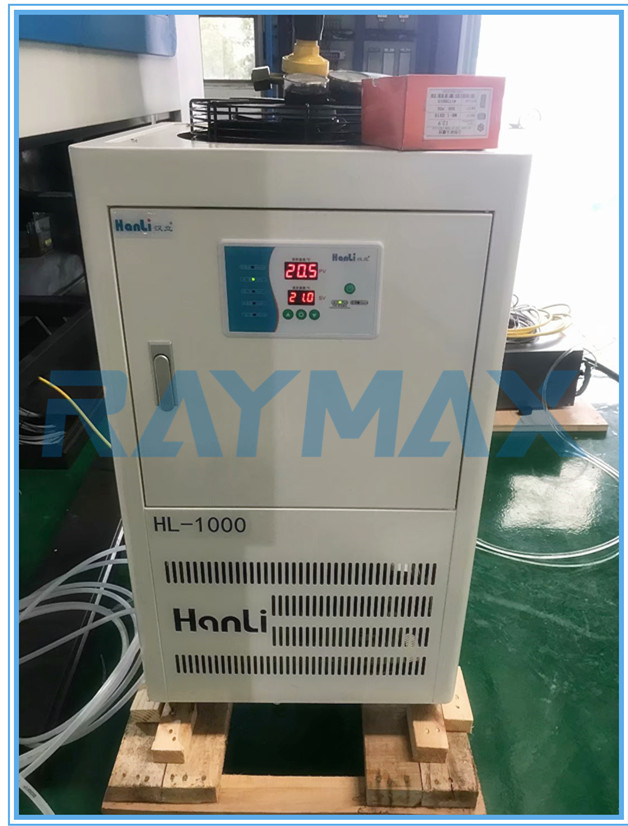

- Cooling Mode: WATER COOLING

- Control Software: cypcut

- Place of Origin: China

- Brand Name: BEILIN/Raymax

- Laser Source Brand: IPG

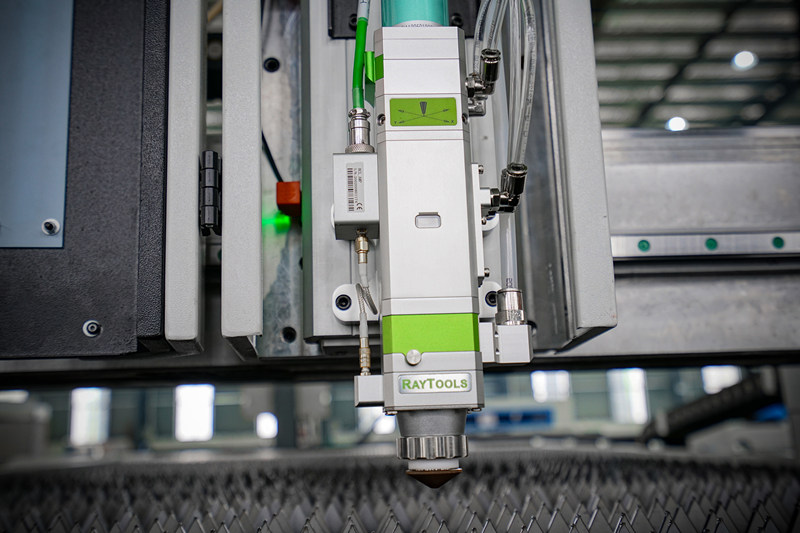

- Laser Head Brand: Raytools

- Servo Motor Brand: fushi Japan

- Guiderail Brand: Tiwin

- Control System Brand: cypcut

- Weight (KG): 6800 KG

- Key Selling Points: Automatic

- Warranty: 3 years

- Applicable Industries: Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use, Retail, Advertising Company

- Mode of Operation: continuous wave

- Configuration: 4-axis

- Products handled: Sheet Metal

- Feature: Water-cooled

- Certification: ce

- After-sales Service Provided: Online support

- After Warranty Service: Video technical support

- Local Service Location: United States

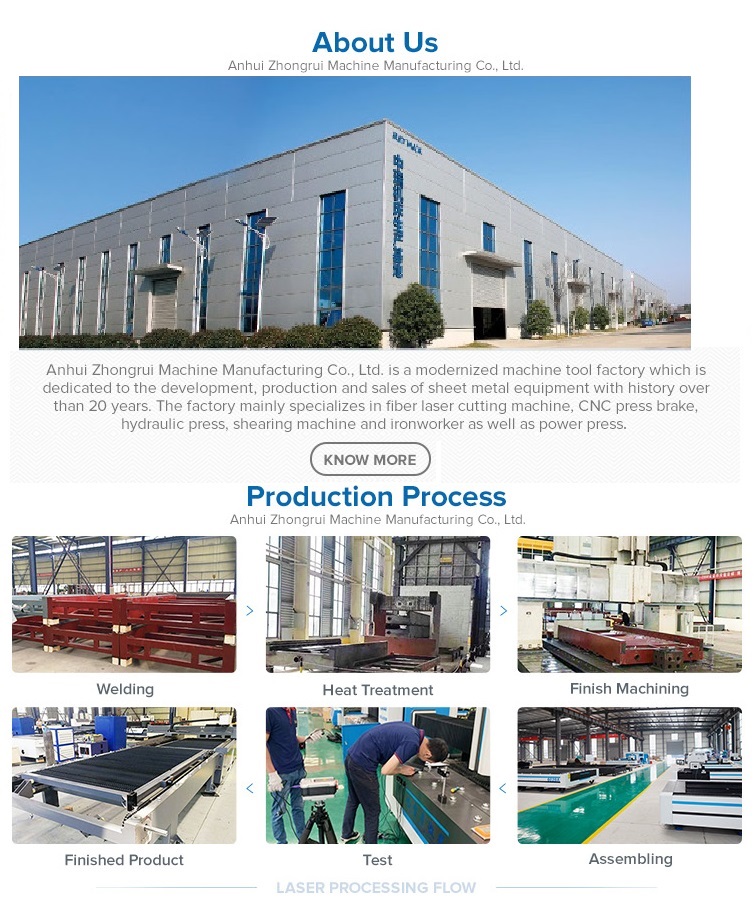

More Details

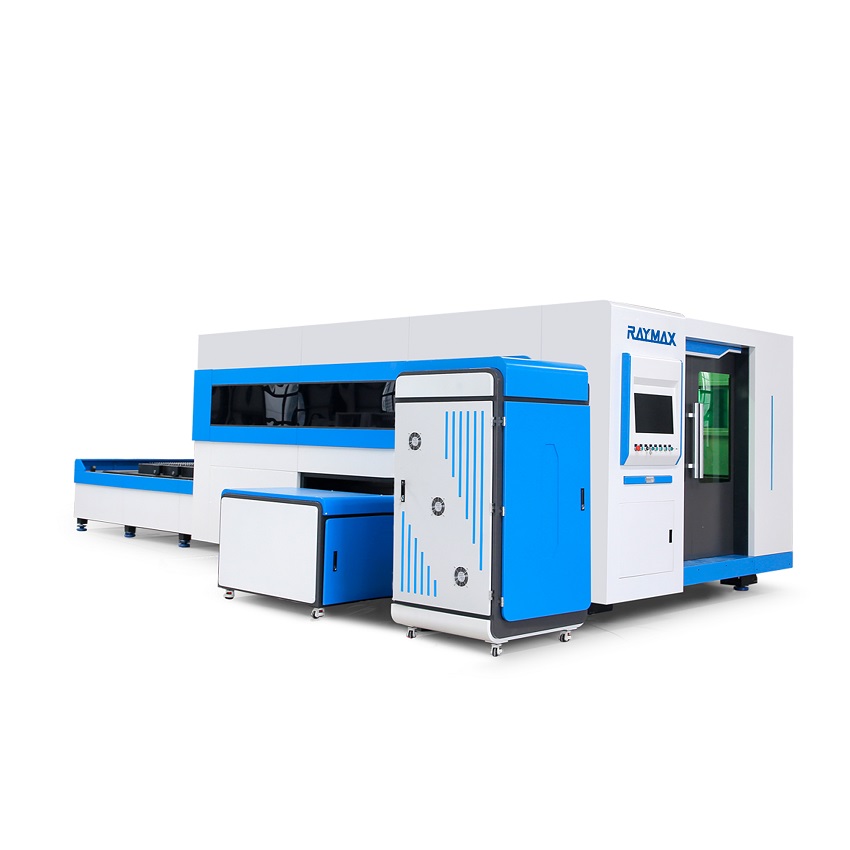

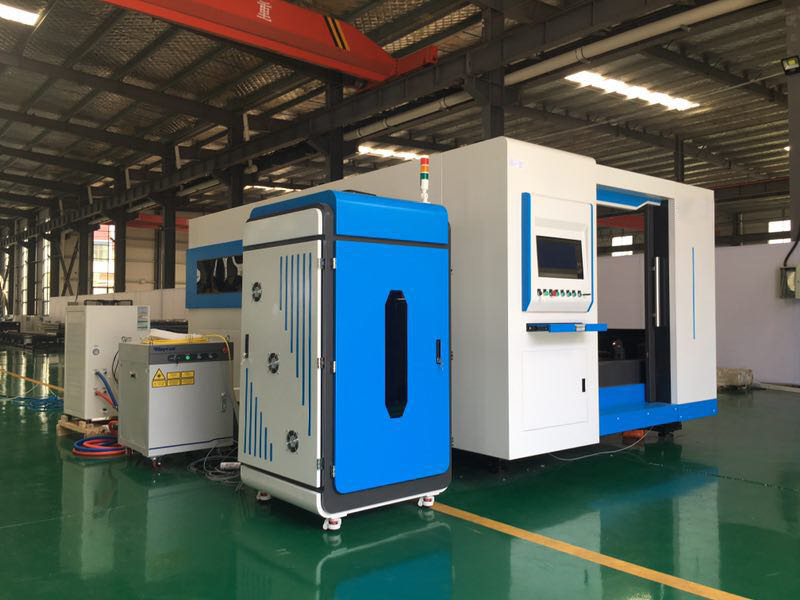

Exchange table fiber laser cutting machine 3015

Fiber laser cutting machine equipment can meet the needs of types of sheet metal parts production, except they are equipped with advanced fiber laser.

The Fiber Lasers bring you a cost effective, low maintenance, low operating cost, environmentally friendly solution to your organization.

Raytools fiber laser head ,the laser head can automatically focus, and imported Japan Yaskawa servo motors and drives, high precision, high speed, large torque, performance is stable and durable, ensure the high speed operation of the whole machine.

The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 5-10 years.

We deliver a machine that provides quality cutting and tolerances with small productivity loss between jobs, equating to higher return on investments.

Main feature:

1. High-performance servo transmission equipment, imported gear rack and linear guide, also adopted the Harley laser independent research and development of aluminum alloy extrusion bar, gantry lathe bed ,to ensure that the equipment of high speed, extremely precision.

2. Maximum simultaneous positioning speed: 160m/min

3. Quick and easy installation

4. Up to 300% faster cutting High wall plug efficiency (>30%)

5. Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

6. Resonator life is over 100,000 working hours.

7. Double ball screw close-loop system and imported open-type CNC system, ensure high accuracy and high working efficiency during

high speed cutting.

8. Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading, improving efficiency.

9. Open structure is easy and convenient for material uploading and unloading.

10. Drawer collectingdevice makes receiving materials more convenient.

Details Images

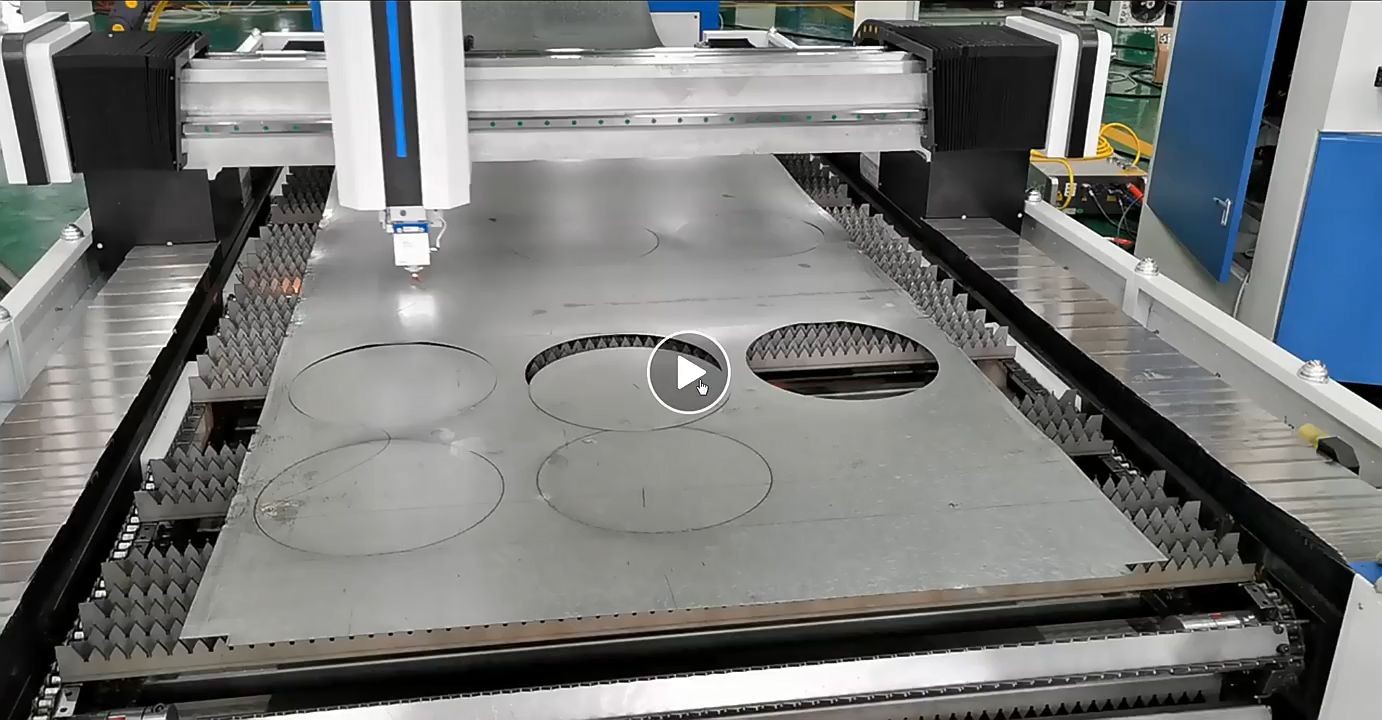

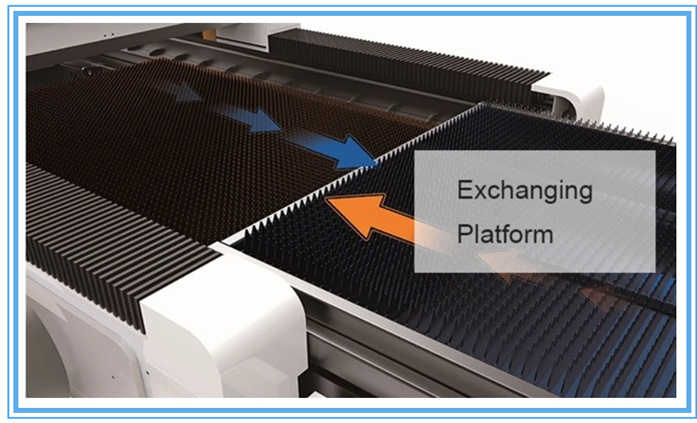

Exchanging plateplateform

1. Rapid exchanging between two platforms greatly improve work efficiency. Rack and pinion transmission system has higher accuracy, saving feeding time, making operation more efficient.

2.Adopt pipe-plate and multiple pipe welding structure or Triangle structure. Strong shock absorption and wear resistance.

3.Good casting and cutting performance. Excellent lubricity, corrosion resistance and dimensional stability.

4.Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

Exact CNC controller

1. With the professional automatci typeseting software ,the cutting plate availability increase 1%-5%,cutting productivity 10%-30%, significantly improve the cut quality ,process data management, data collection and statistics and other data management functions, visualization integrated interface, simple operation, easy to learn CNC controller is the most widely used and the most sophisticated controller.

2. It is high speed response , mainly used in high-level laser cutting machine. its processing technology and the powerful graphics editing features are very reliable and

practical, extremly High precision.

| Style | processing area | Laser power | Maximum velocity of movement | X/Y axis positioning accuracy | X/Y/Z axis stroke |

| 750W | 1500X3000 MM | 1500W | 120 M/MIN | ±0.05 mm | ±0.02 mm |

| 1000W | 2000*4000 MM | 2000W | 120M /MIN | ±0.05 mm | ±0.02 mm |

| 6000W | 3000*6000 MM | 3300W | 120 M /MIN | ±0.05 mm | ±0.02 mm |

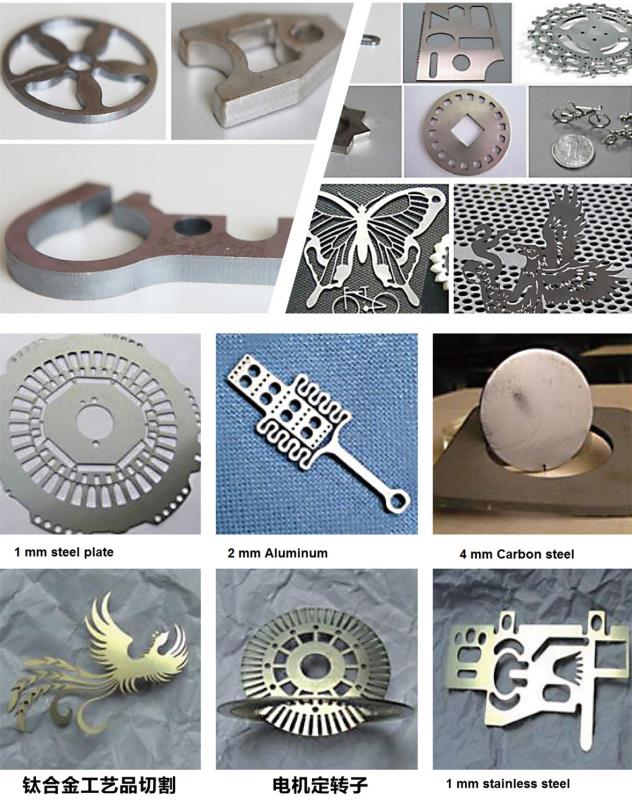

Application

Application Materials:

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries:

Soullon Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts,Glasses Frame, Electronic Parts, Nameplates, etc.

Cutting sample

After-sales service:

Training to install:

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/SKYEPE/Wechat and so on, when you meet some problems of installation, using or adjusting. (Recommended)

B. You can come to Zhongrui Laser factory for training. We will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

C. Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator for both of our engineers during the training period. Training Time: 5~7 days

FAQ

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training

video, user's manual along with the machine. 95% customers can learn by themselves.

Q: how do I operate this machine?Is training necessary?

A:The machine is mainly controlled by software.Simple, not complicated.Before delivery, we will make a simple operation manual and pictures, and provide the software manual.Generally speaking, an operator who is not familiar with the fiber laser marking machine can still operate it well.According to customer requirements, we can send technicians to the customer's factory for machine training, or when the customer needs to come to our factory for machine training.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe tranportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: What material can fiber laser machine cut?

A: Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, copper, brass and other metal sheet and pipe.