Quick Description

- Slider Stroke (mm): 160 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 350 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 1600

- Width of Working Table (mm): 900 mm

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: raymax

- Material / Metal Processed: Stainless steel, ALLOY, Carbon steel, Aluminum, PVC

- Automation: Automatic

- Extra Services: Machining

- Weight (KG): 2870

- Motor Power (kw): 5.5 kw

- Key Selling Points: Multifunctional

- Warranty: 2 years

- Applicable Industries: Hotels, Machinery Repair Shops, Farms, Home Use, Food Shop, Printing Shops, Construction works , Advertising Company

- Showroom Location: United States, Italy, Spain, Thailand, Australia

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, Gear, Pressure vessel, Engine, Gearbox

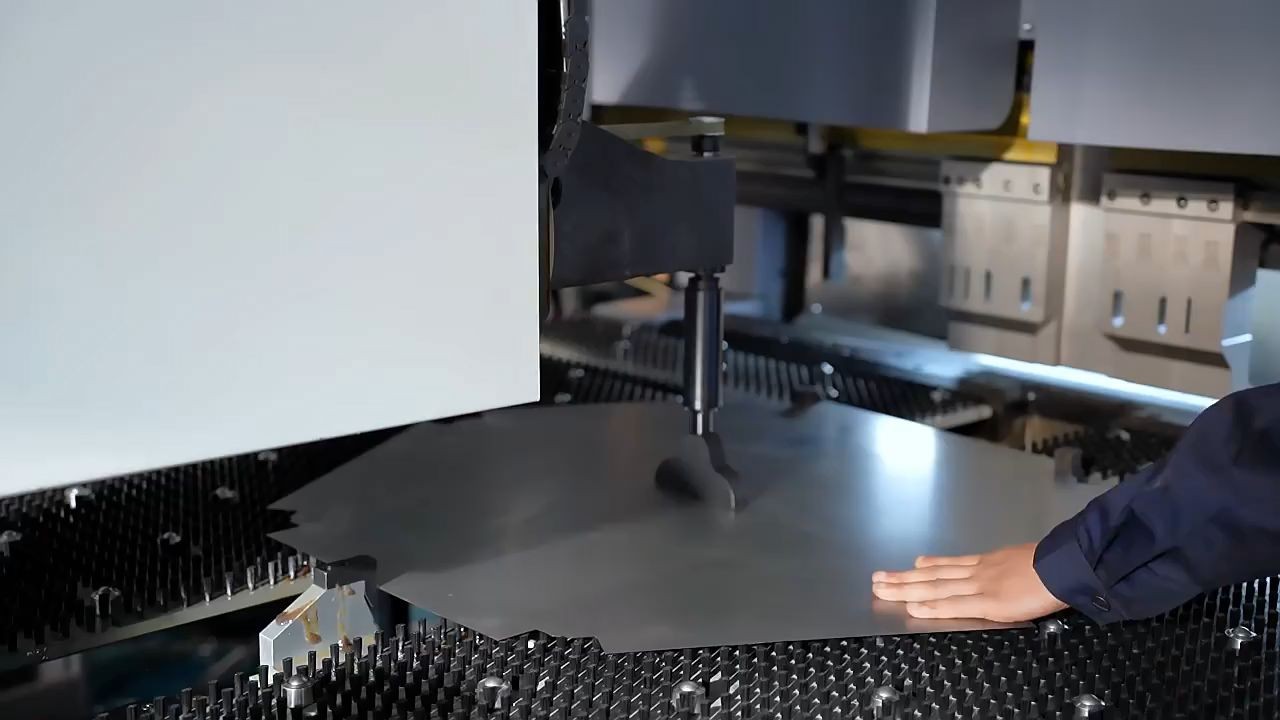

- Application: Stainless Plate Bending

- Color: Customizable

- Material: Metal Steel Sheet

- CNC System: Delem Hydraulic CNC Press Brake

- Usage: Metal Sheet Folding

More Details

Performance characteristics

Integral welding processing structure

International famous brand electro-hydraulic servo valve and grating ruler form closed loop control mode

High slider position feedback accuracy, accurate and smooth operation, good synchronization performance, bending accuracy, high slider repeat positioning accuracy.

Rear baffle material can be according to customer demand to adopt more complete function of the rear baffle material shaft of the rear baffle material mechanism.

The hydraulic system adopts integrated control system, which reduces the installation of pipelines, eliminates oil leakage, ensures the working stability of machine tools, and makes the appearance scientific and beautiful.

Hydraulic deflection automatic compensation mechanism, eliminate the impact of slider deformation on the quality of the workpiece, CNC system automatically adjust the amount of compensation, easy and accurate operation.

CNC system using the Netherlands DELEM, Italy ESA, Switzerland CYBELEC and other well-known brands dedicated CNC bending machine system.

| Working Source | Hydraulic |

| Bending Material | Carbon steel, stainless steel, aluminum, mild steel |

| Controller | CNC Controller, CT8, CT12, DA53T, DA58T, DA66T, DA69T |

| Press Brake Usage | Bending plate into different AngleCurling Plate into Hinge Flattening plate |

| Voltage | 220V/380V according to customer request |

| Tooling | A set of standard tooling |