Quick Description

- Slider Stroke (mm): 250 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 500 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 5000 mm

- Width of Working Table (mm): 220 mm

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: RAYMAX/BEILIN

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Weight (KG): 12000

- Motor Power (kw): 37 kw

- Key Selling Points: High Productivity

- Warranty: 2 years

- Applicable Industries: Hotels, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Printing Shops, Energy & Mining

- Showroom Location: United States, Spain, Thailand

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Usage: Metal Sheet Rolling Bending

- Name: press brake machine

- Type: <± 0.05mmHydraulic

- Product name: Hydraulic Cnc Bending Machine

- Control system: CT8/CT12/DA41/E21/DA52/DA66T

- Main Motor: Siemens Germany

- Electrical components: Schneider France Brand

- Hydraulic System: Bosch Rexroth Germany

More Details

Product Description

Electro-Hydraulic tandem cnc press brake

1. Double linkage machine by CNC system can be stand-alone or dual -operating

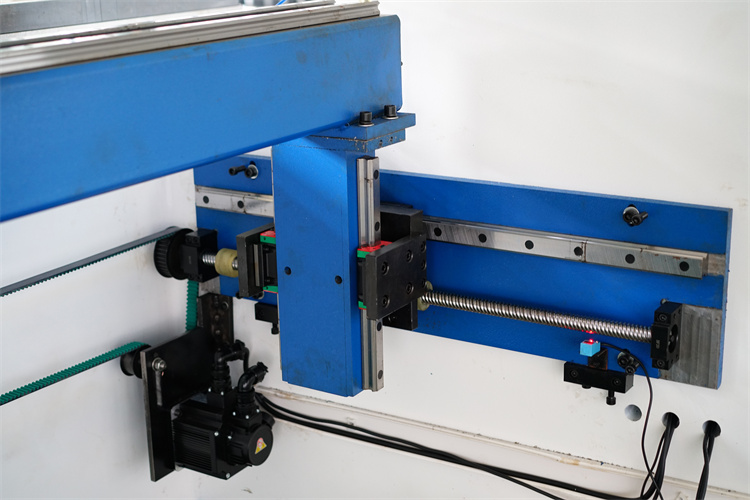

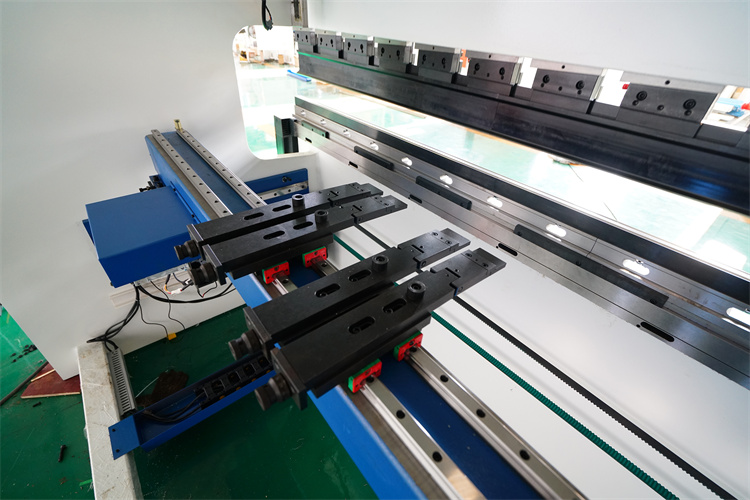

2. It's standard 2 shafts back gauge system, as to complex shape work pieces, 3 or 4 shafts back gauge system and corresponding dies are available for your option.

3. Press brake using fully closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to CNC system by bilateral gratings, then CNC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider Y1, Y2 running on the same frequency, maintaining the parallel state of the worktable.

4. According to state of sheet metal on the press brake, CNC system can automatically control the table deflection compensation yielding uniform length of all workpieces angles.

5. The use of hydraulic deflection compensation gives access to uniform full length workpieces. Hydraulic deflection compensation consists of a set of oil cylinders under the worktable, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative positions with slider keep unchanged. Compensation valves are subject to plate thickness and properties of material to be bent.

| Product Name | Eelctro-hydraulic synchronous cnc press brake /bending machine |

| Bending material | carbon steel, stainless steel ,aluminum,iron |

| Certificate | ISO9001,SGS,CE |

| Applicable | auto spare parts, electrical apparatuses ,metal crated and cabinet,metal plate processing |

Detailed Images

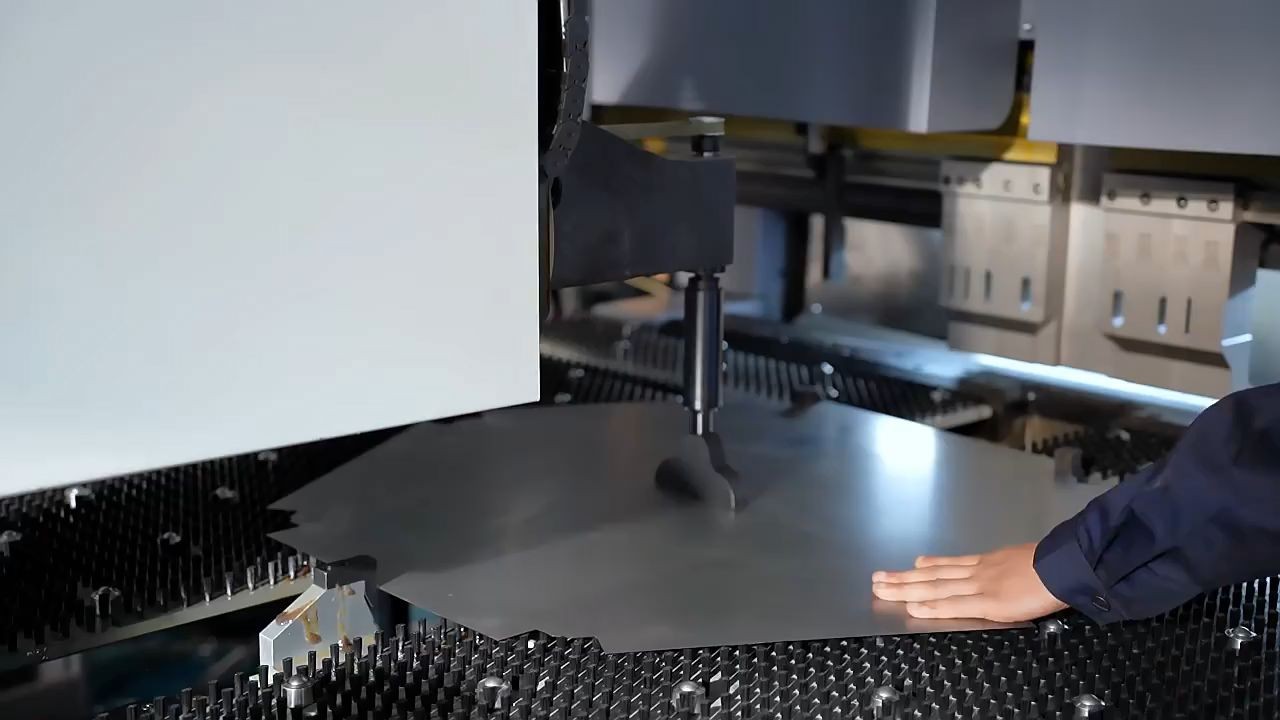

1. The main mechanical structure of a machine tool is composed of frame,column, slider, worktable, main cylinder , back carrier and other parts.Through finite element analysis and optimization design by three-dimensional software,the structural strength and rigidity of each main component can be fully ensured.

2. Internal stress of welded parts can be eliminated by tempering and vibration aging.

Schneider Electric components

It conforms to international standards, is safe and reliable, has a long service life, and has strong anti-interference ability.

The electrical cabinet is equipped with a

Cooling device

The movement and location of the left and right cylinder are controlled by axis Y, and Y, closed loop control system consists of servo motor ,bidirectional pump electro--hydraulic servo valve, grating ruler

Quick clamp

1.The mold can be installed and removed to the left and right when pull the red handle

2.The mold can be installed up and down when press the button

3.scale more accuracy

Greting ruler

Measuring step 5 um connecting rod connection

Large mounting tolerances