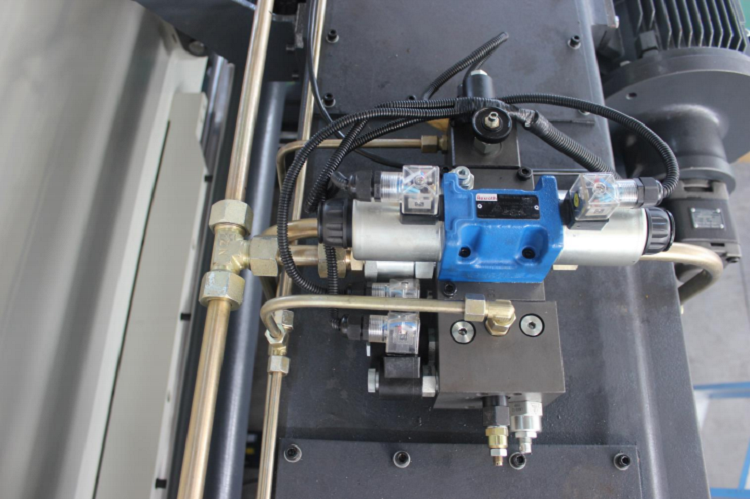

Quick Description

- Slider Stroke (mm): 200 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 320 mm

- Machine Type: Torsion Bar

- Length of Working Table (mm): 3200

- Width of Working Table (mm): 900 mm

- Condition: New

- Place of Origin: China

- Material / Metal Processed: Stainless steel, Carbon steel, Aluminum

- Automation: Automatic

- Weight (KG): 9200

- Motor Power (kw): 11 kw

- Key Selling Points: Automatic

- Warranty: 1 Year

- Applicable Industries: Hotels, Building Material Shops, Manufacturing Plant

- Showroom Location: United States, Italy, Spain

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, Engine

- Function: Steel Metal Bending

- Color: Optional Color

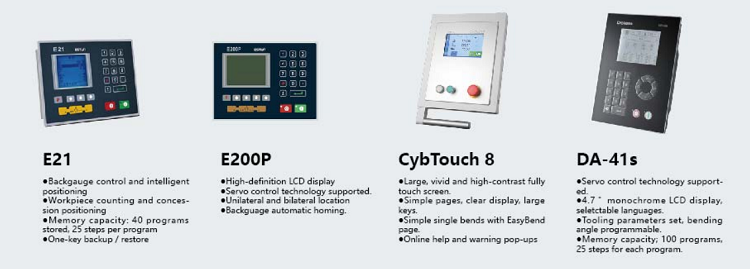

- Control system: E21/DElEM/CYBELEC

More Details

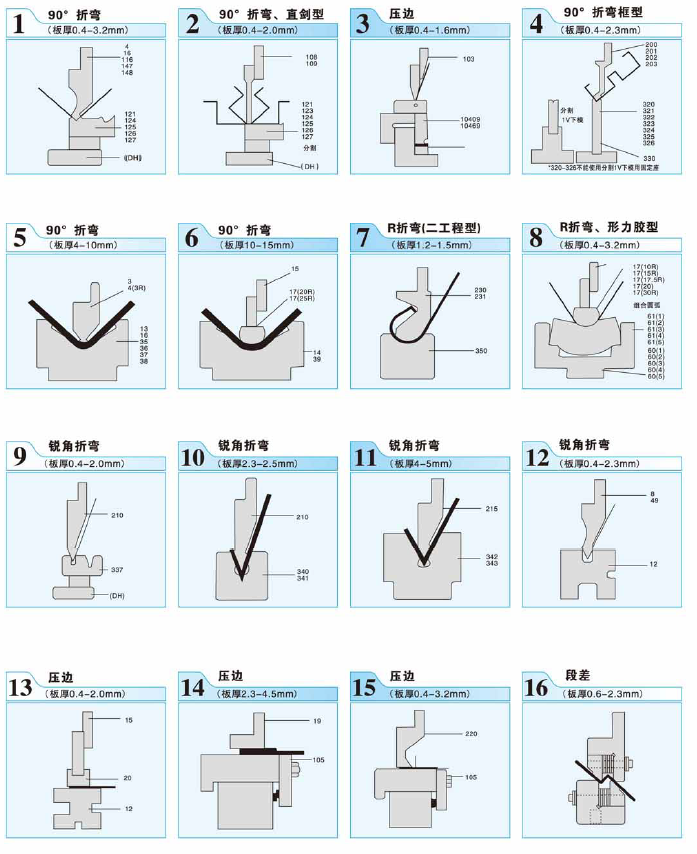

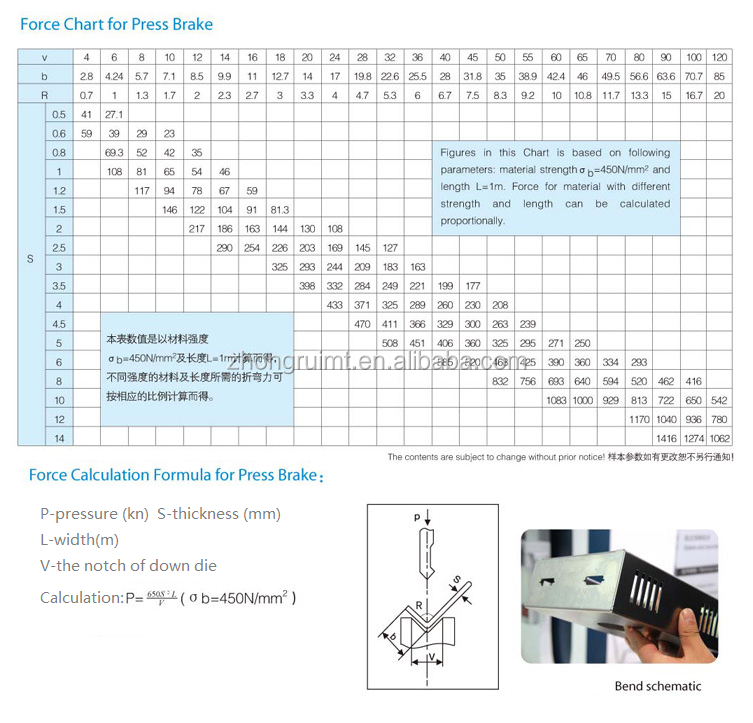

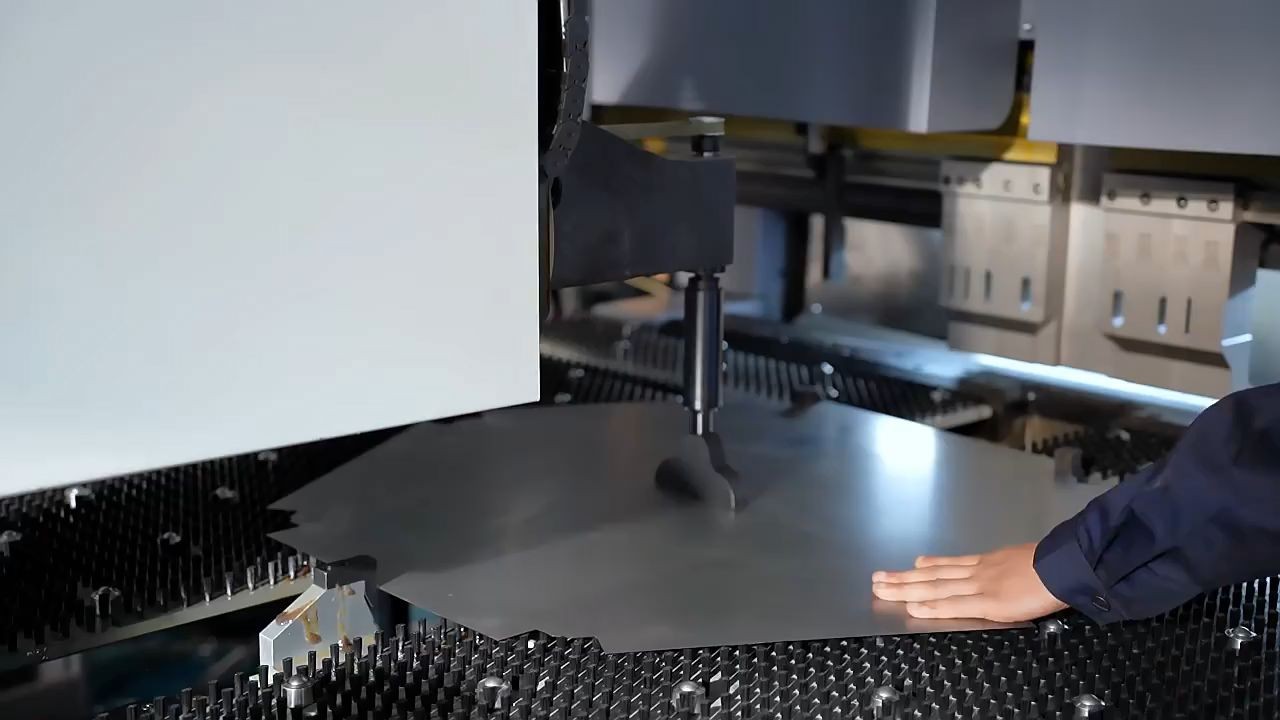

Bending machine is the use of the mold (general or special mold) to bend the cold metal sheet into various geometric sections of the workpiece.

1. The main mechanical structure of a machine tool is composed of frame, column, slider, worktable, main cylinder, back carrier and other parts. Through finite element analysis and optimization design by three-dimensional software, the structure strength and rigidity of each main component can be fully ensured .

2. Internal stress of welded parts can be eliminated by tempering and vibration aging.

3. The oil cylinders fitted on both sides adopt closed loop control mode which is composed of Germany electro-hydraulic servo valve and imported grating ruler, breaking through the stroke control mode of traditional mechanical stop bending machine ,ensuring the high precision of the glide position, the accurate and stable operation, the high precision of bending

1: The whole machine is in sheet plate welded structure ,with internal stress eliminated by vibration aging technology,high strength and good rigidity of machine.

2: Double hydraulic oil cylinder is applied for upper transmission ,provided with mechanical limit stopper and synchronous torsion bar, typical of stable and reliable operation, as well as high precision.

3: Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of gliding block ,and fitted with digital device ,easy and quick in use.

4: Upper die is fitted with deflection compensation device.

| Working Source | Hydraulic |

| Bending Material | Carbon steel, stainless steel, aluminum, mild steel |

| Controller | NC Controller, E21, E220P, DA41, CT12 |

| Press Brake Usage | Bending plate into different AngleCurling Plate into Hinge Flattening plate |

| Voltage | 220V/380V according to customer request |

| Tooling | A set of standard tooling |

Configuration

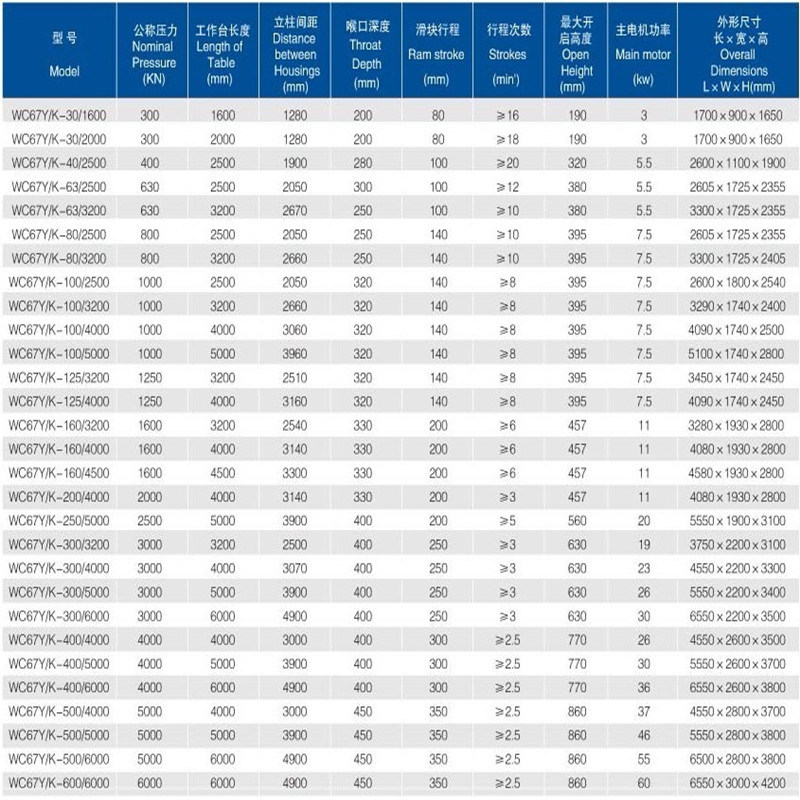

Quick clamp

1. The mold can be installed and removed to the left and right when pull the red handle

2. The mold can be installed up and down when press the button

3. scale more accuracy

Electric cabinet

Siemens or Schneider world famous brand

Electrical system Our press brake adopts Schneider electrical components. The high quality electric parts can make the machine performing well even the electricity is not stable and customers can easily get the replacement

Torque synchronous control system

Adopt steel torsion bar synchronization system with high accuracy . At the 2 ends of the ram, there are 2 synchronizing devices so that the ram movement is always parallel to the worktable ,this structure highlights the effect of balancing motion during operation

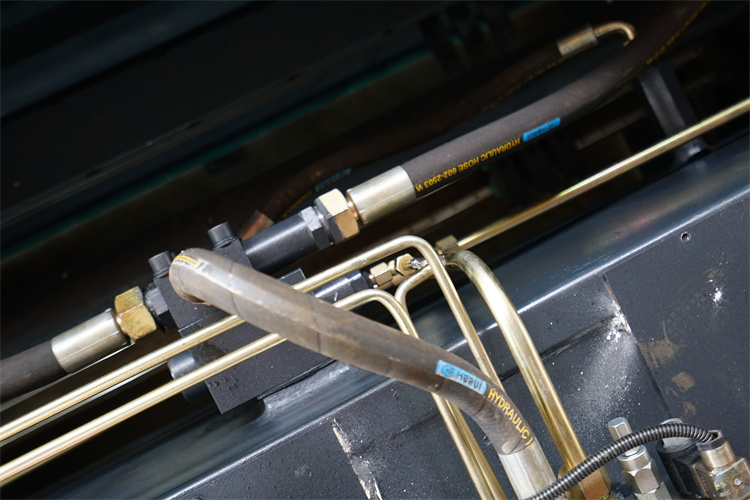

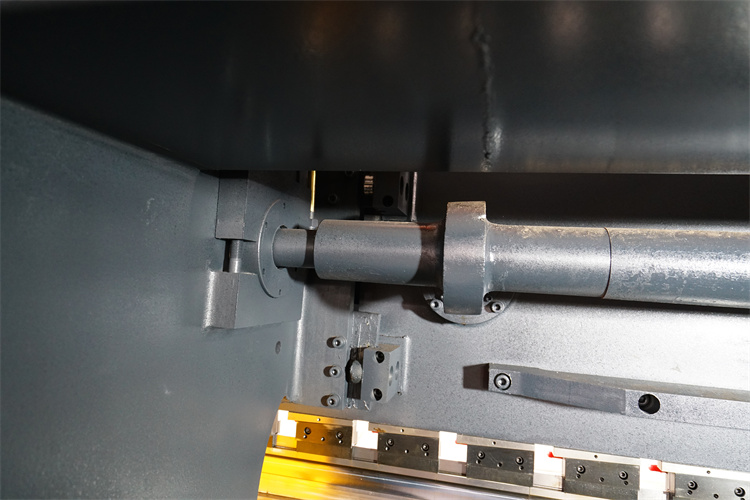

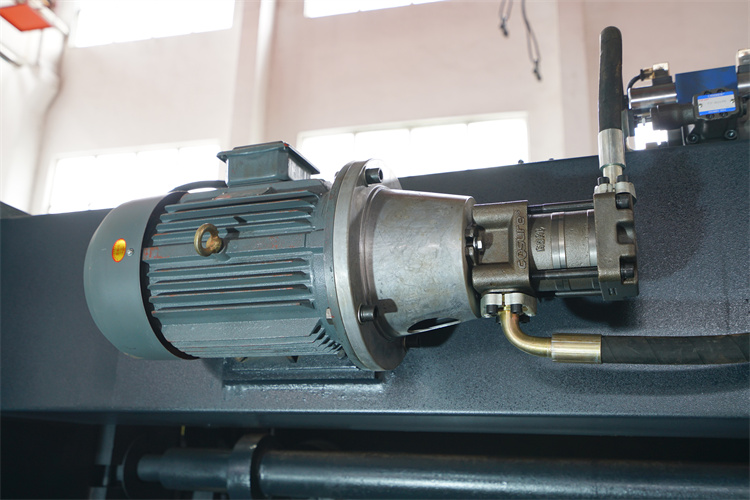

BOSCH-REXROTH hydraulic system

Use BOSCH-REXROTH integrated hydraulic control system that limits the number of pipe connections,making it more reliable and easy for maintenance

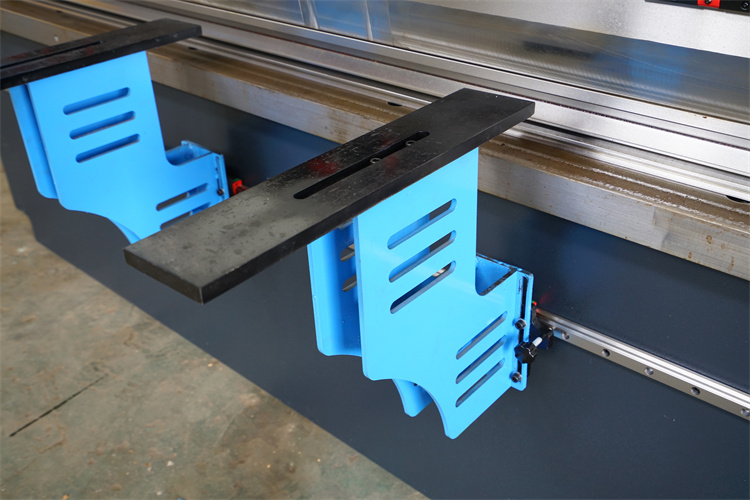

Front Plate Support

Movable front material support on linear guider can move left and right by hand very easy.

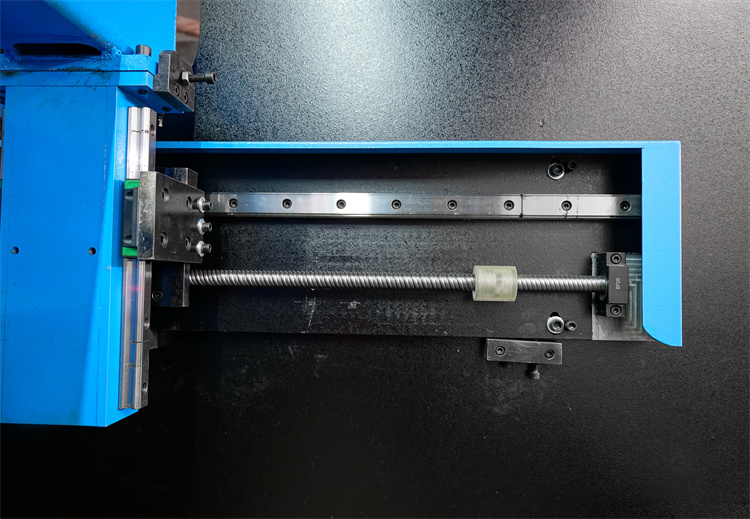

Ball Screw & Linear Guide

Adopting HIWIN ball screw and linear guide to improve the machine backguage accuracy.

Germany Siemens Motor

Using Siemens motor guarantee the machine service life and improve the machine working stability.

South Korea Foot Switch

Lengthened the service life and improved operational sensitivity

E21 control system

Positioning control of backgauge.

One-way and two-way positioning function,effectively eliminating the screw gap.

Retreat escape function,automatic search reference function.

One-button backup and restore function.

Power protection function.

Application

The folded sheet metal bending machine has high productivity and high working accuracy, using different shapes of up and down mould, can be bent into various shapes artifacts, slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending can be achieved relatively complex shape workpiece, when equipped with the corresponding equipment, can also make a punch.

Feature

1. Standard two axis control (X.Y)

2. Mechanical torque synchronization(torsion bar)

3. The whole machine is in sheet plate welded structure, with internal stress eliminated by vibration aging technology, ensure machine high strength and good rigidity

4. Electrical control and manual fine-tuning mode are adopted for distance of rear stopper and stroke of slider, and installed with digital display device, easy and quick for operator

5. Quick clamping is equipped,it is convenient for operator to install and get offer punch