Quick Description

- Application: LASER CUTTING

- Applicable Material: Metal

- Condition: New

- Laser Type: Fiber Laser

- Cutting Area: 3000*1500mm

- Cutting Speed: 8mm/min

- Graphic Format Supported: AI, DXF, PLT, BMP, Dst, Dwg, LAS, DXP

- Cutting Thickness: 0.2-8mm

- CNC or Not: Yes

- Cooling Mode: WATER COOLING

- Control Software: CNC

- Place of Origin: Anhui, China

- Brand Name: RAYMAX

- Laser Source Brand: RAYCUS

- Laser Head Brand: Raytools

- Servo Motor Brand: Schneider

- Guiderail Brand: HIWIN

- Control System Brand: Cypcut

- Weight (KG): 40 KG

- Key Selling Points: High-accuracy

- Optical Lens Brand: Wavelength

- Warranty: 2 years

- Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works

- Machinery Test Report: Provided

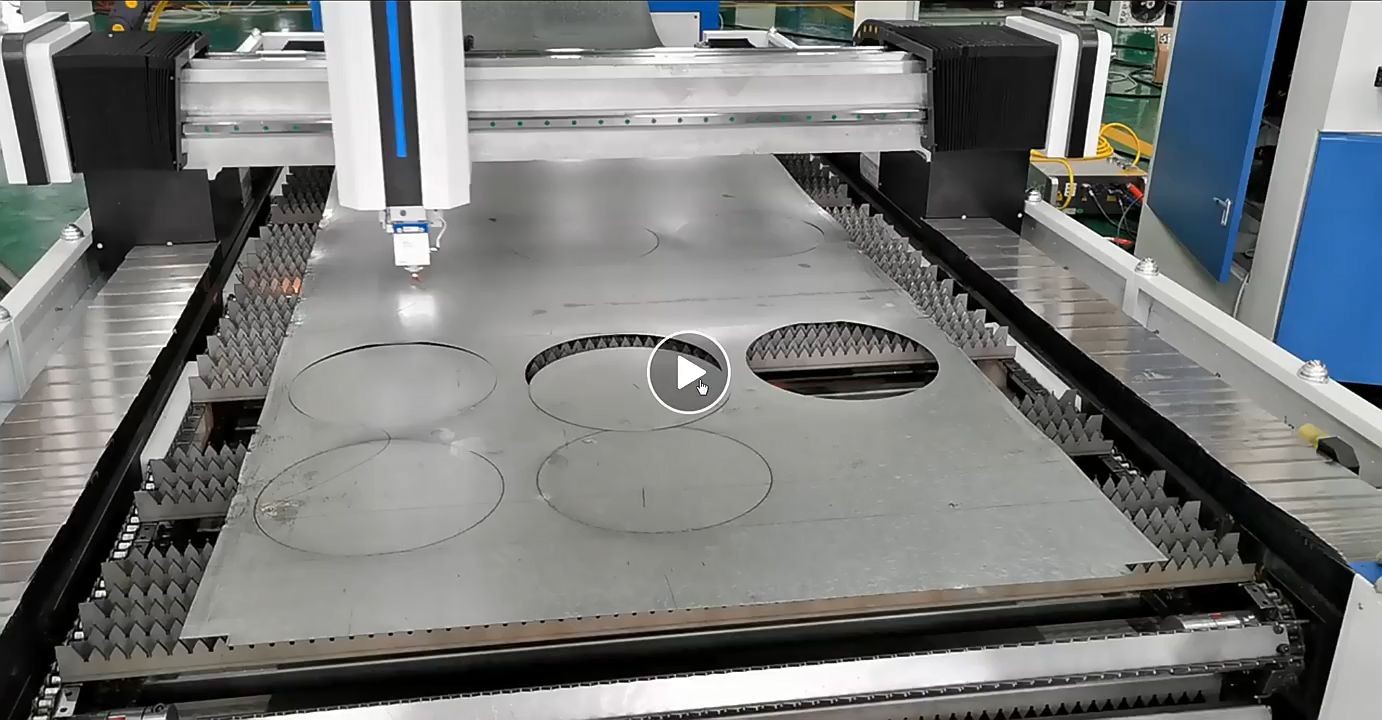

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Pressure vessel, Motor, Bearing, Gear, Pump, Gearbox, Engine, PLC

- Mode of Operation: continuous wave

- Configuration: 4-axis

- Products handled: Sheet Metal and Tube

- Feature: SERVO-MOTOR

- After-sales Service Provided: Engineers available to service machinery overseas

- Keyword: CNC Fiber Laser Cutting

- Applicaion: metal laser cutting machine

- Application Material: metal, stainless steel ,carbon steel

- Type: fiber laser cutter

- Controller: cnc laser cutting machine

- Working power: 380V/50Hz/50A

- Continuous working time: 24 hours

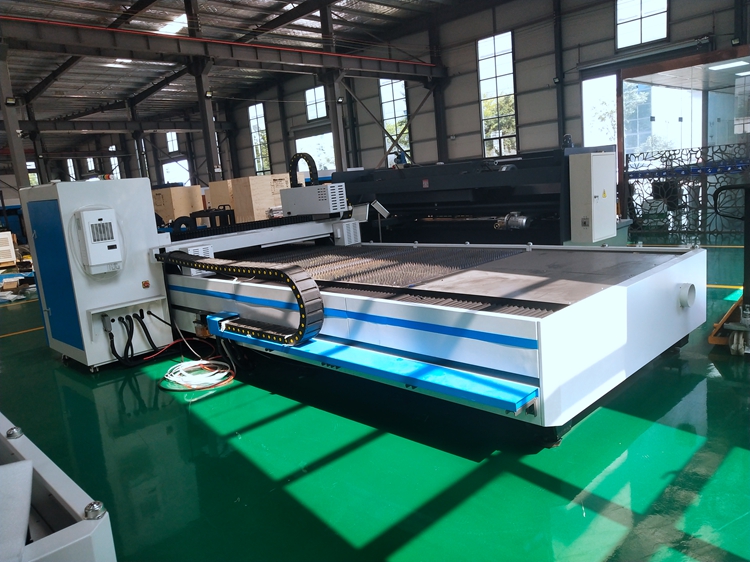

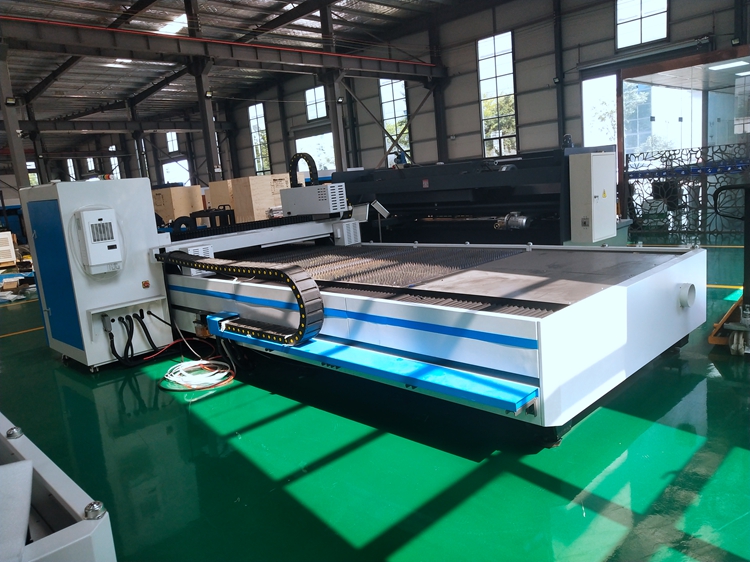

- Overall Demension: 3770*2280*1400mm

- Marketing Type: New Product 2019

More Details

Product Description

Advantages

1. Speed

When cutting mild steel, stainless steel, and aluminum plate, fiber laser cutting machine of equal power is 2-3 times faster than CO2 laser with smooth cutting .

2. Cost

The maintenance cost of CO2 laser cutting machine is very high. Not only front lens and back lens are expensive, but also the working life of turbine bearings.

At the same time CO2 laser cutting machine photoelectric conversion rate is only 8% to 10%, and it consumes too much gas when cutting. But fiber laser cutting machine photoelectric conversion rate can reach 30%, which is more economic.

3. Maintenance

We know that CO2 laser cutting machine laser has complex structure, inconvenient maintenance and high operation requirements. But the CNC fiber laser cutting machine has simpler maintenance. Besides,tolerance of dust, shocks , temperature and humidity in poor work environment.

Standard Components

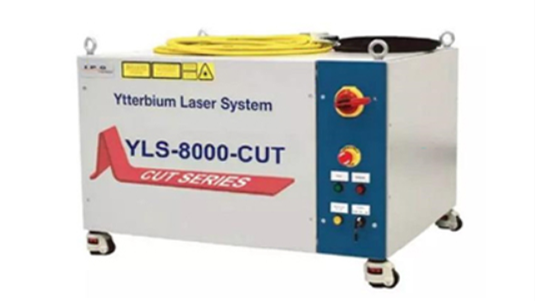

1. Laser generator Wuhan Raycus or Germany IPG

2. Laser cutting torch Raytools

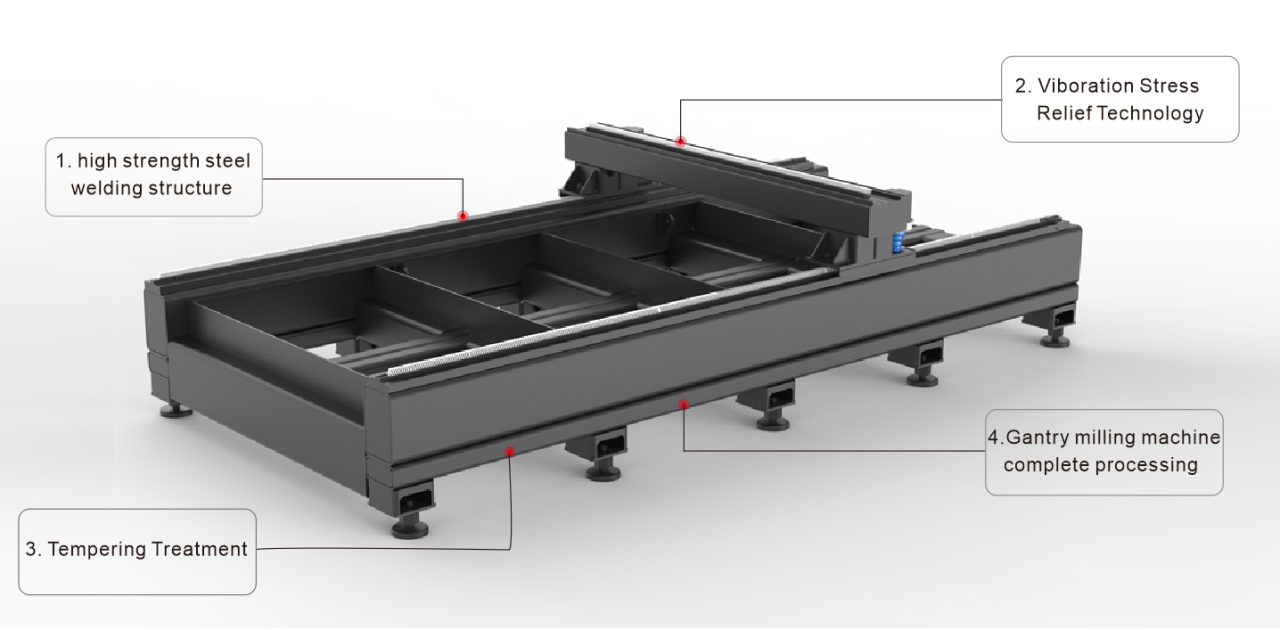

3. Cutting bed Steel plate welding

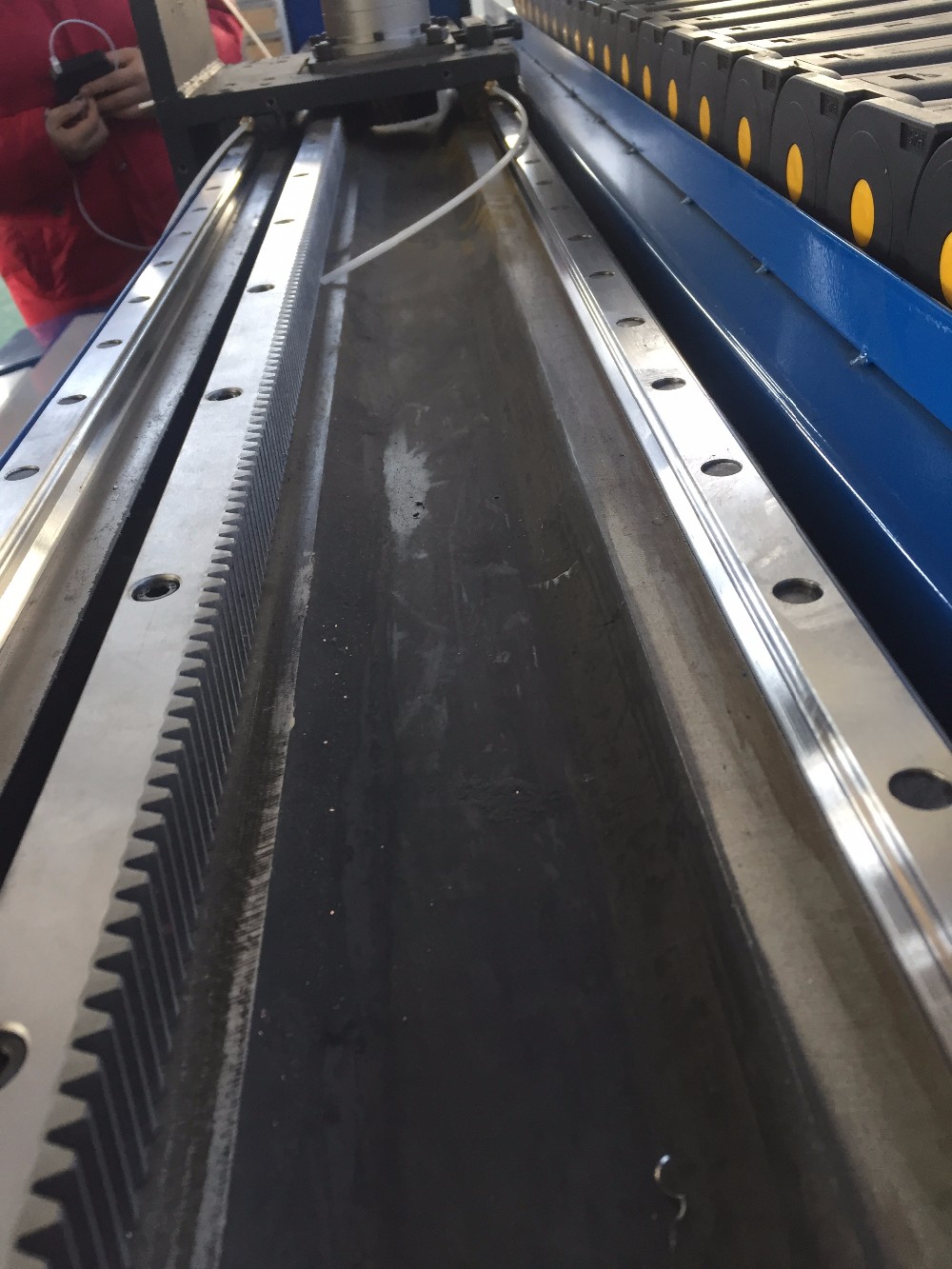

4. X, Y gear rack Germany ROR or Taiwan YYC

5. Guide rail Taiwan Hiwin

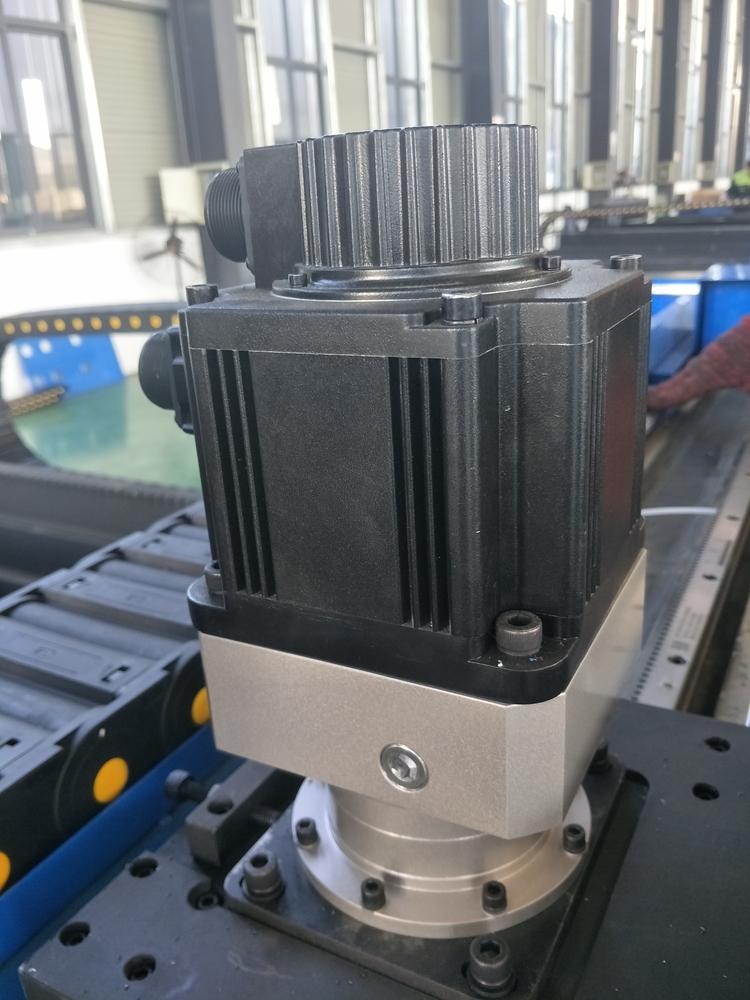

6. AC servo motor & driver Japan Fuji

7. Proportional valve Japan SMC

8. Reducer Japan SHIMPO

9. Gas circuit control Japan SMC

10. CNC system and software CYPCUT

11. Water cooling machine Guangzhou S&A

12. Dust Absorption set

Optional Components

1. Screw air compressor

2. Vacuum cleaner set

3. Voltage Regulator

4. Laser focusing lens

5. Laser protective windows

6. Laser ceramic rings

7. Laser Nozzles

Detailed Images

Raycus Laser

China Wuhan Brand

IPG Laser

Germany Brand

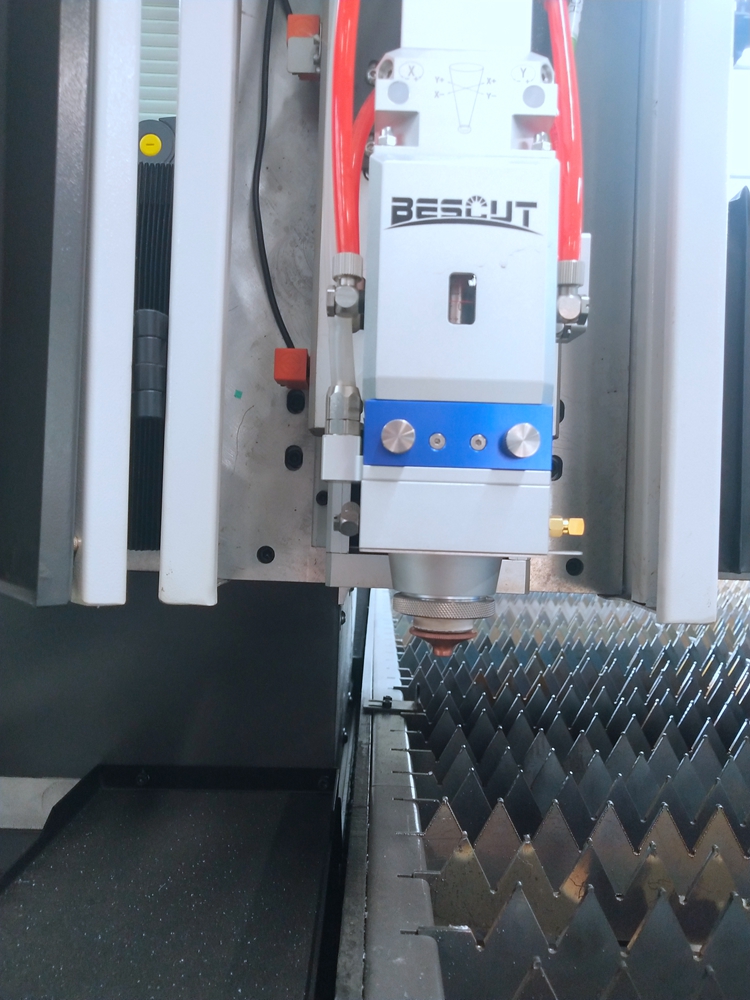

Laser cutting torch

Automatic focus torch

Control Unit

CNC contol system & schneider electrics & laser

Guide rail gear rack protection cover

stainless steel plate and nylon flexible tube

ABS drag chain

air tube ,electric wire, laser fiber

YYC linear guide and gear rack

Gear and reducer

Water cooling device

S&A Brand

FUJI servo motor and reducer

durable

Remote Control

wireless control

Lubricants pump

pump oil on guide rail