Quick Description

- Slider Stroke (mm): 160 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 350 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 1600

- Width of Working Table (mm): 900 mm

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: raymax

- Material / Metal Processed: Stainless steel, ALLOY, Carbon steel, Aluminum, PVC

- Automation: Automatic

- Extra Services: Machining

- Weight (KG): 2870

- Motor Power (kw): 5.5 kw

- Key Selling Points: Multifunctional

- Warranty: 2 years

- Applicable Industries: Hotels, Machinery Repair Shops, Farms, Home Use, Food Shop, Printing Shops, Construction works , Advertising Company

- Showroom Location: United States, Italy, Spain, Thailand, Australia

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pump, Gear, Pressure vessel, Engine, Gearbox

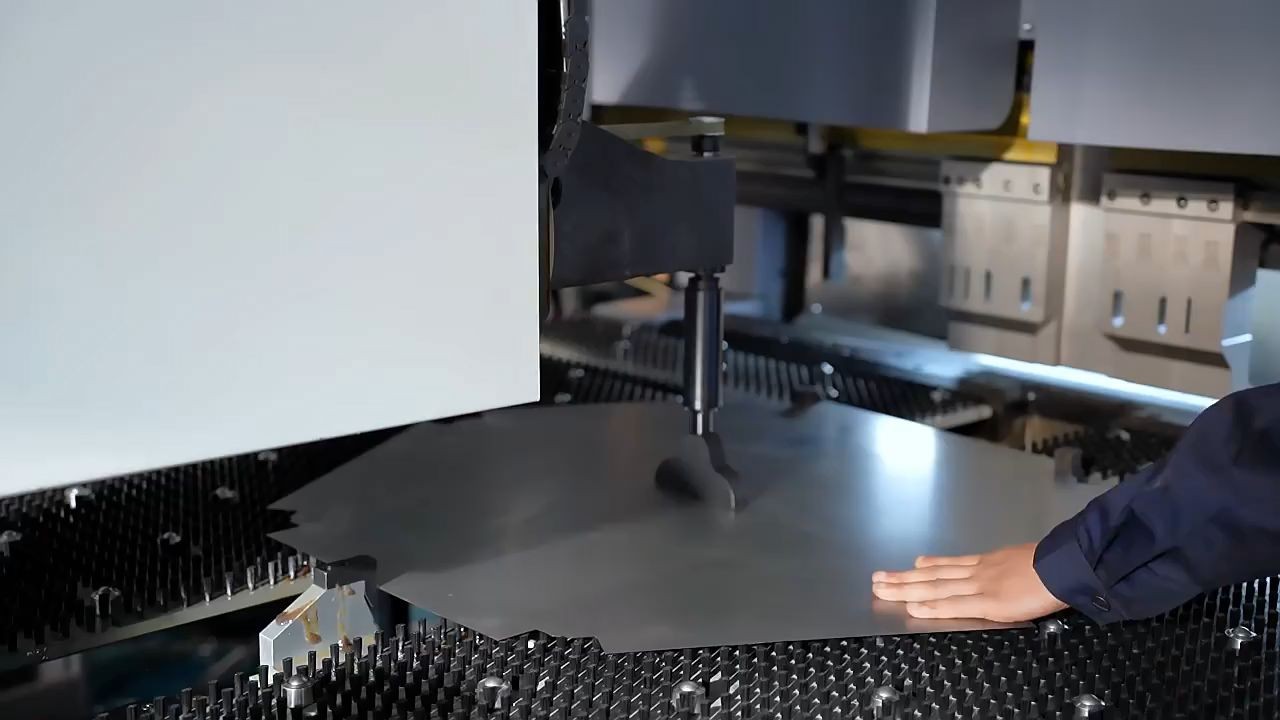

- Application: Stainless Plate Bending

- Color: Customizable

- Material: Metal Steel Sheet

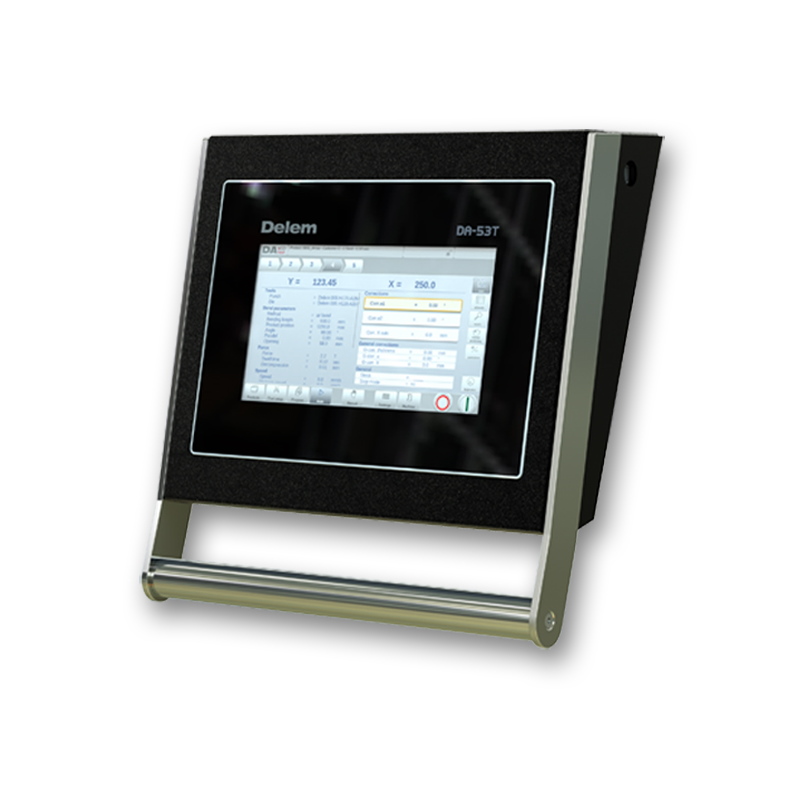

- CNC System: Delem Hydraulic CNC Press Brake

- Usage: Metal Sheet Folding

More Details

Products Description

Performance characteristics

Integral welding processing structure

International famous brand electro-hydraulic servo valve and grating ruler form closed loop control mode

High slider position feedback accuracy, accurate and smooth operation, good synchronization performance, bending accuracy, high slider repeat positioning accuracy.

Rear baffle material can be according to customer demand to adopt more complete function of the rear baffle material shaft of the rear baffle material mechanism.

The hydraulic system adopts integrated control system, which reduces the installation of pipelines, eliminates oil leakage, ensures the working stability of machine tools, and makes the appearance scientific and beautiful.

Hydraulic deflection automatic compensation mechanism, eliminate the impact of slider deformation on the quality of the workpiece, CNC system automatically adjust the amount of compensation, easy and accurate operation.

CNC system using the Netherlands DELEM, Italy ESA, Switzerland CYBELEC and other well-known brands dedicated CNC bending machine system.

| Working Source | Hydraulic |

| Bending Material | Carbon steel, stainless steel, aluminum, mild steel |

| Controller | CNC Controller, CT8, CT12, DA53T, DA58T, DA66T, DA69T |

| Press Brake Usage | Bending plate into different AngleCurling Plate into Hinge Flattening plate |

| Voltage | 220V/380V according to customer request |

| Tooling | A set of standard tooling |

Controller

CybTouch 8

◈ 2D graphic part creation with manual sequencing.

◈ 7” color graphic CRT screen, 800 x 480 pixels with LED backlight control

◈ Controls 3 axes (with 4th axis as option)

◈ Punch depth calculation.

◈ Angle and back gauge correction.

◈ EasyBend page

◈ Various automatic calculations of bend functions.

◈ Bending sequences and programs can be memorized.

◈ Angle, pressure and crowning management.

CybTouch 12

◈ 12” color graphic TFT screen, 800 x 600 pixels with LED backlight control

◈ Controls 4 axes.

◈ Various automatic calculations of bend functions.

◈ Angle, pressure and crowning management.

◈ Offline 2D software available.

◈ Bend allowance calculation.

◈ Pressure-crowning calculation.

◈ Angle and back gauge correction. stick for data transfer/backup.

CybTouch VP88

◈ 19" streamlined glass touch screen

◈ Easy-to-operate and friendly human-machine interface

◈ Efficient 2D graphic drawing and fast and accurate 2D programming solutions

ESA875

◈ 21.5 ”16: 9 LCD Full HD Multitouch GlassOnly maxi screen.

◈ 4 axes (up to 128 axes as an option)

◈ Advanced HMI graphic tools. Possibility to develop complex and 3D interfaces, simplifying user interaction

DA53T

◈ “Hot-key” touch navigation

◈ 10.1" high resolution colour TFT

◈ Up to 4 axes (Y1,Y2 2 aux. axes)

◈ Crowning control

◈ Tool / material / product library

◈ Servo and frequency inverter control

◈ Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

◈ USB memory stick interfacing

◈ Profile-T offline software solution

DA58T

◈ 2D graphical touch screen programming

◈ 15" high resolution colour TFT

◈ Bend sequence calculation

◈ Crowning control

◈ Servo and frequency inverter control

◈ Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

◈ USB, peripheral interfacing

◈ Profile-T offline software

DA66T

◈ 2D graphical touch screen programming mode

◈ 17" high resolution colour TFT

◈ Full Windows application suite

◈ Delem Modusys compatibility (module scalability and adaptivity)

◈ USB, peripheral interfacing

◈ User specific application support within the control's multitasking environment

◈ Sensor bending & correction interface

◈ Profile-TL offline software

DA69T

◈ 3D and 2D graphical touch screen programming mode

◈ 3D visualisation in simulation and production

◈ 17" high resolution colour TFT

◈ Full Windows application suite

◈ Delem Modusys compatibitily (module scalability adaptivity

◈ USB, peripheral interfacing

◈ User specific application support within the controllers multitasking environment

◈ Sensor bending and correction interface profile-T3D offline software

Configuration

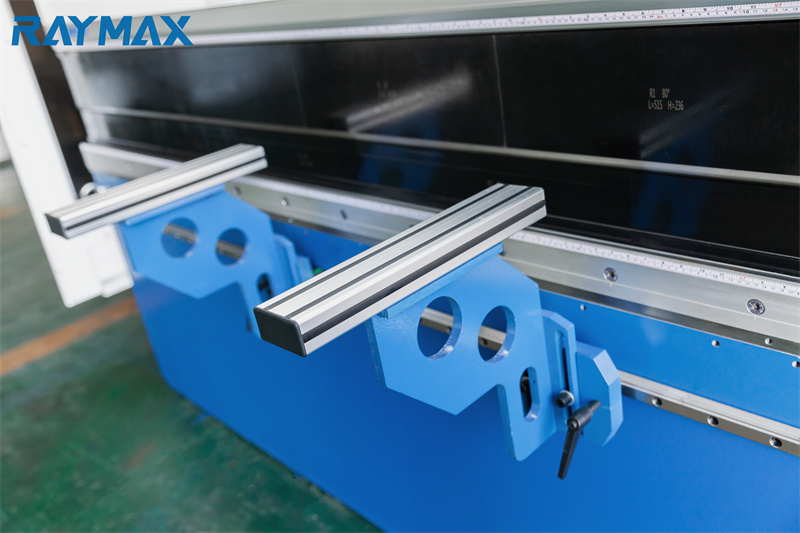

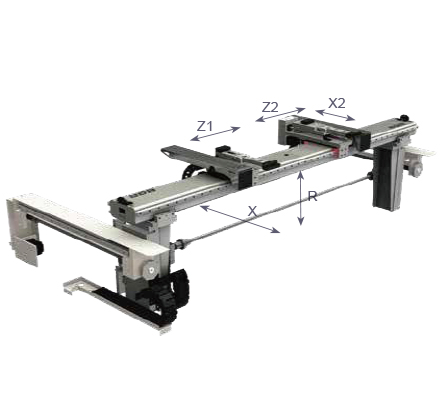

CNC Backguage

Press brake are provided are equipped with a backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

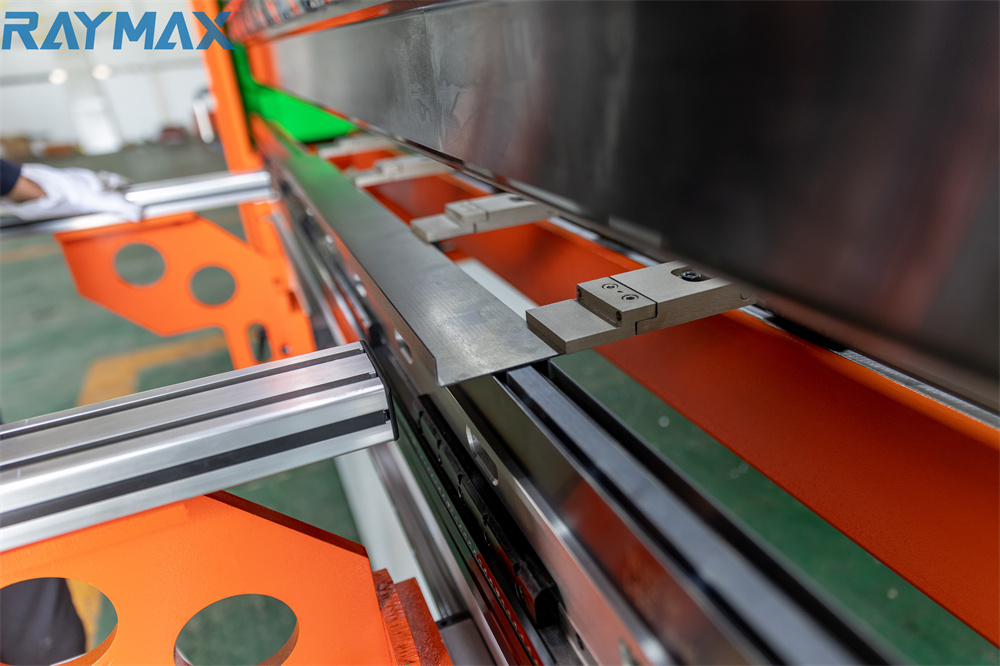

Fast Clamping

The standard equipped fast clamp will help you replace the top punch in very short time. Convenient and time-saving. Fast intermediate loading and unloading function to improve work efficiency.

1. The mold can be installed and removed to the left and right when pull the red handle

2. The mold can be installed up and down when press the button

3. scale more accuracy

Press Brake Toolings

The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use.

Front Plate Support

Movable front material support on linear guider can move left and right by hand very easy.

Safety fence

Protect the operator from the risk of crushing between the punches and dies. It's also the most economical solution.

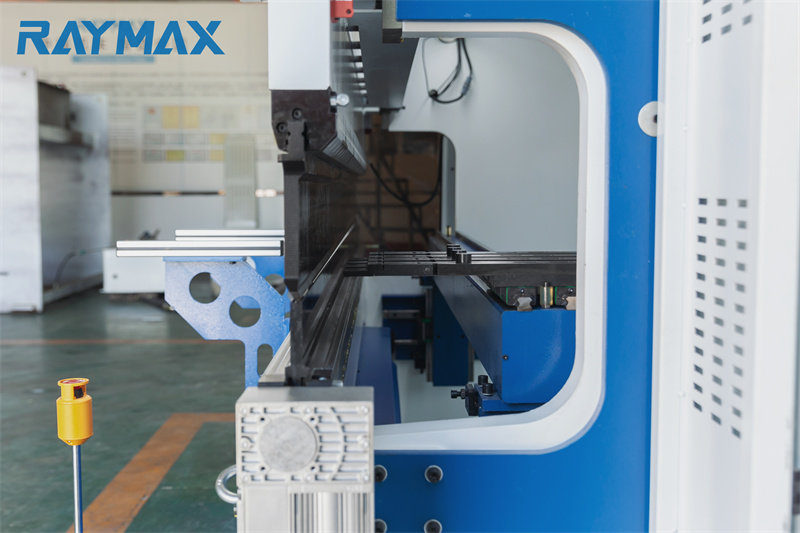

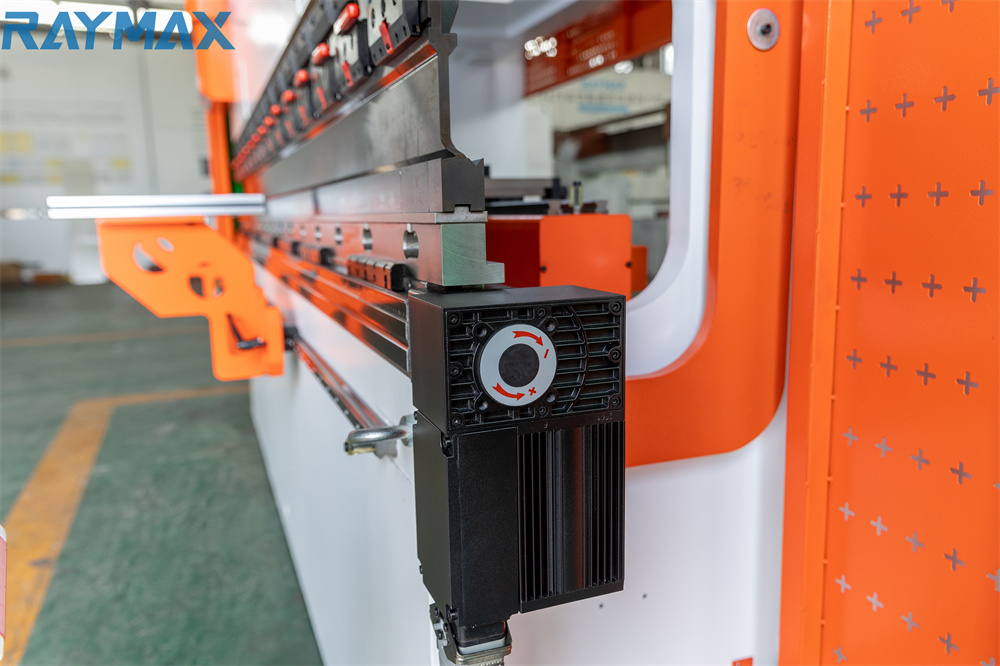

Bosch Rexroth Hydraulic System and Siemens Motor

Germany Bosch Rexroth integrated hydraulic valve block. Hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid. Using Siemens motor guarantee the machine service life and improve the machine working stability.

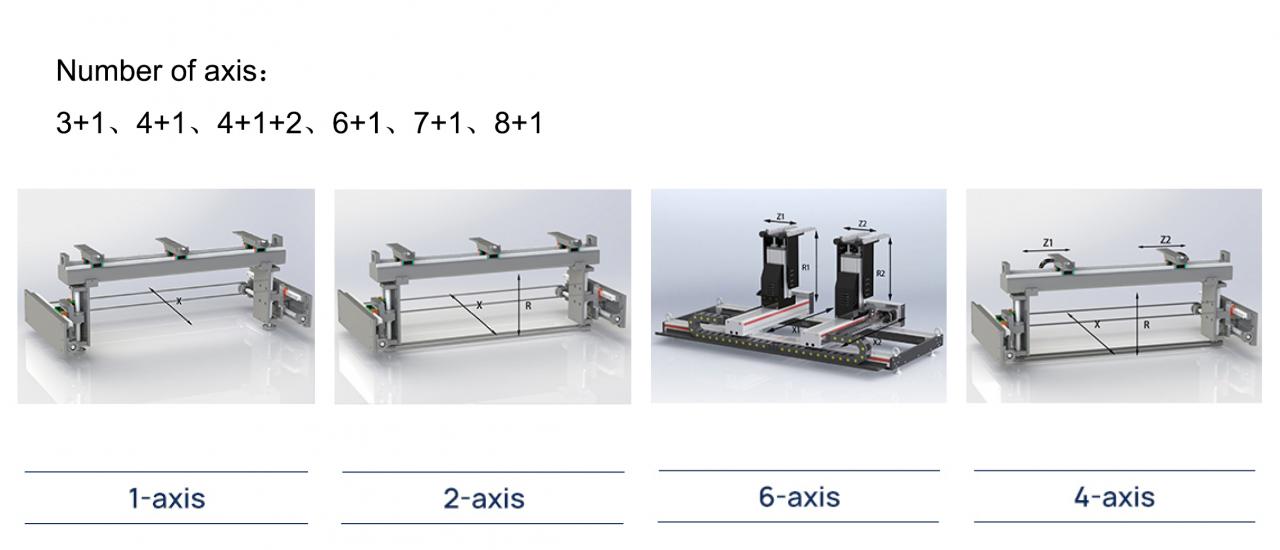

Grating Ruler

Incremental or absolute ruler based on optical or magnetic techniques for synchronous bending machines.

The reader is guided by a self-aligning and self-cleaning slider with a spring system.

Safety limit switch, positioned at both ends.

Adjustable output cable position and optional zero reference index make the ruler symmetrical and suitable for bending machine two columns.

Crowning Table

Compensation crowning table can promise the bending precision for angle and strightness when you bend the workpiece.

Ball Screw & Linear Guide

Adopting HIWIN ball screw and linear guide to improve the machine backguage accuracy.

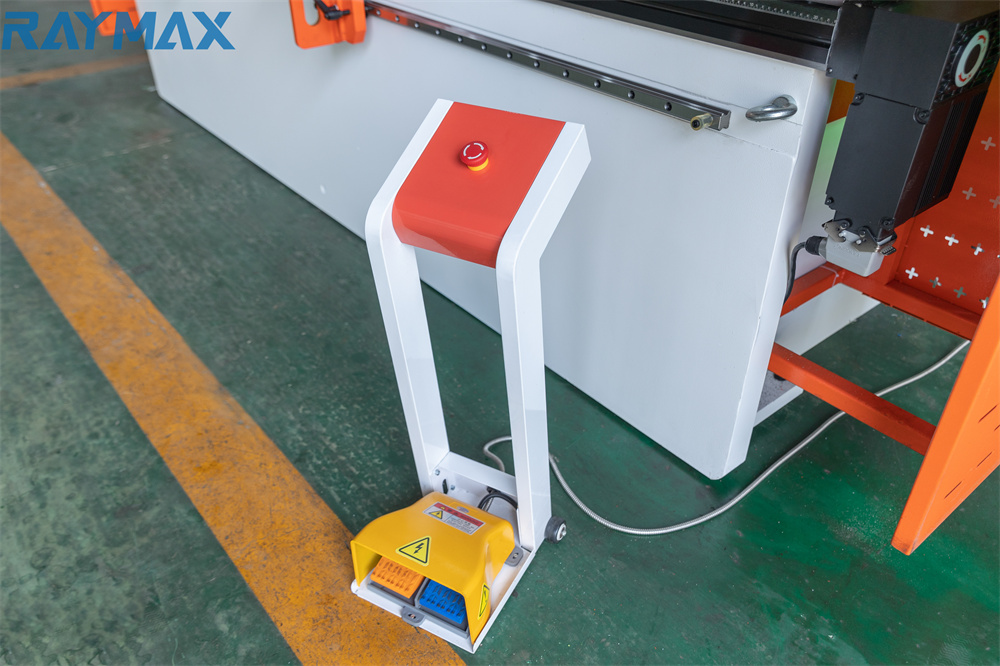

Karcon Pedal switch with emergency button

South Korea KACON pedal switch , it is movable and can stop the machine anytime by the emergency button

Company Profile

Anhui zhongrui machine manufacturing Co;Ltd

Anhui zhongrui machine manufacturing Co;Ltd was build in 2002. It is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experienced engineers and designers, which makes it be a well-known brand of sheet metal fabricating machinery in China. We are a modernized machine tool factory which is dedicated to the development, production and sales of sheet metal equipment with history over than 20 years. The factory mainly specializes in press brake, shearing machine, hydraulic press machine, fiber laser cutting machine and punching machine. Professionally provide complete sets of metal sheet and profile processing machinery for automobiles, ships, railways, aviation, electric power, petrochemicals, light industry and other industries; products are sold all over the country and exported to Southeast Asia, Middle East, Western European, South America and other regions. We have passed the I S O 9 0 0 1 certification and C E certification. We continued to strengthen research and development of new products, introduce the c n c technology which comes from Italy and Germany. C N C press brake, C N C fiber laser cutting machine that we produced have achieved a real sense of C N C automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers’ satisfaction, we have realized strict control of products from design, manufacturing process, inspection to complete machine delivery, installation and service.

Powerful Equipment

FAQ

Q: How I can choose a suitable machine?

A: Tell us the Max Working area, the material and its thickness you want to cut, we can help choose the best suitable machine.

Q: Are you a factory or a trading company?

A: We are a manufacturer. Our company was founded in 2001, and has more than 20 years of production experience.

Q: Where is your factory located?

A: Our company is in Maanshan, Anhui Province, which is only half an hour’s drive from Nanjing Lukou Airport. If you visit our company, we will arrange a special bus to meet you at the airport.

Q: How does your factory do regarding quality control?

A: Quality is priority factor for the development our cooperation 20 years. We have CE and ISO certifications.

Q: Can we visit your factory?

A: Yes, of course, welcome you visit our factory and check our machine quality on spot. After you confirm the coming time, tell me in advance, then we will go to airport or train station to pick you up on time. And one professional will together with you in the factory, any question will be solved on spot as first time.

Q: How long does it take to deliver the machine?

A: Generally, we will deliver the goods within 30 days. If the machine belongs to non-standard customized products, the time will be longer, but the longest time will not exceed 50 days.

Q: Can we be your agent?

A: Welcome, we are looking for Global agent we will help agent improve the market and supply all the

service like machine technical problem or other after-sales problem.

Q: Payment Terms?

A: T/T, L/C, Western Union, Paypal, Alibaba Secure payment, etc. 30% deposit and 70% payment before delivery. If you are our special customer, we can accept better payment method.