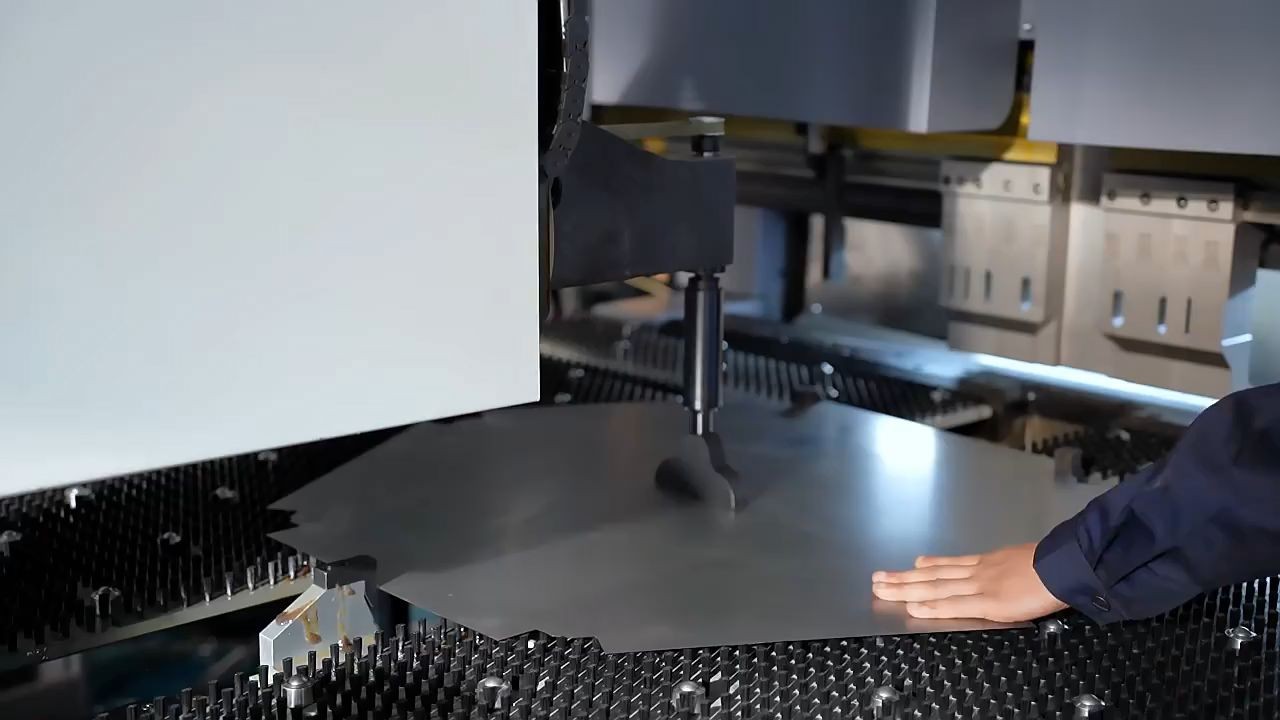

A Hydraulic Metal Sheet Plate Stainless Steel Press Brake Machine is a powerful industrial machine used in metal fabrication for bending and forming metal sheets and plates. This machine uses hydraulic force to apply pressure to metal sheets and plates, allowing them to be bent and formed into precise angles and shapes.

The hydraulic system of the press brake machine consists of a pump, cylinder, and hydraulic oil tank. The pump generates hydraulic pressure, which is transmitted to the cylinder. The cylinder then uses this pressure to bend the metal sheets and plates. The hydraulic system is highly efficient and allows for precise control over the bending process.

The press brake machine is equipped with a variety of tools and features that allow for maximum flexibility and precision. These include different types of punches and dies that can be used for a variety of bending applications. The machine can also be programmed with different bending sequences, allowing for complex shapes and angles to be formed.

One of the main advantages of the Hydraulic Metal Sheet Plate Stainless Steel Press Brake Machine is its ability to handle a wide range of materials. It is specifically designed to work with tough materials such as stainless steel, which can be difficult to bend and shape using other types of machines. This makes it an ideal solution for industries such as aerospace, automotive, and construction, where high-quality and precise metal components are required.

The machine is also highly efficient, capable of bending and forming metal sheets and plates at high speeds. This allows for quick and efficient production runs, making it an ideal solution for businesses that require large volumes of metal components.

In conclusion, the Hydraulic Metal Sheet Plate Stainless Steel Press Brake Machine is a highly versatile and efficient machine that is ideal for metal fabrication applications. It provides precise control over the bending process, allowing for complex shapes and angles to be formed. Its ability to handle tough materials such as stainless steel makes it an ideal solution for industries where high-quality metal components are required.

Quick Description

- Max. Cutting Width (mm): 6000

- Max. Cutting Thickness (mm): 6 mm

- Automatic Level: Semi-automatic

- Shearing Angle: 1*30°

- Blade Length (mm): 3200 mm

- Backgauge Travel (mm): 20 - 500 mm

- Throat Depth (mm): 300 mm

- Condition: New

- Brand Name: Rbqlty

- Power (kW): 7.5 kW

- Weight (KG): 5300 KG

- Place of Origin: Anhui, China

- Voltage: 220V-420V optional, 220v/380v/415v optional

- Dimension(L*W*H): 3700*1610*1620 mm

- Year: 2020

- Warranty: 2 years

- Key Selling Points: Competitive Price

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, France, Brazil, Indonesia, Mexico, Russia, Thailand

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Bearing, Motor, Pump, Gear, PLC

- After-sales Service Provided: Engineers available to service machinery overseas

- Color: Customizable

- Machine type: Hydraulic Cutting Machine Shearing Machine

- Cutting material: SS Steel , mid steel

- CONTROLLER: E21S

- Application: Sheet Metal Industry

- Weight: 5300 kg

- Usage: Shearing Metal Sheet

- Cutting thickness: 6mm