Quick Description

- Machine Type: Single Column Hydraulic Press

- Return Force (kN): 200 kN

- System: Normal

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: raymax

- Weight (T): 2 T

- Motor Power (kw): 14 kw

- Key Selling Points: Competitive Price

- Warranty: 2 years

- Applicable Industries: Farms, Food & Beverage Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Advertising Company, Construction works

- Showroom Location: United States, Spain, Thailand

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 2 years

- Core Components: Bearing, Motor, Pump, Gear, PLC

- After-sales Service Provided: Engineers available to service machinery overseas

- Nominal Pressure: 1000 KN

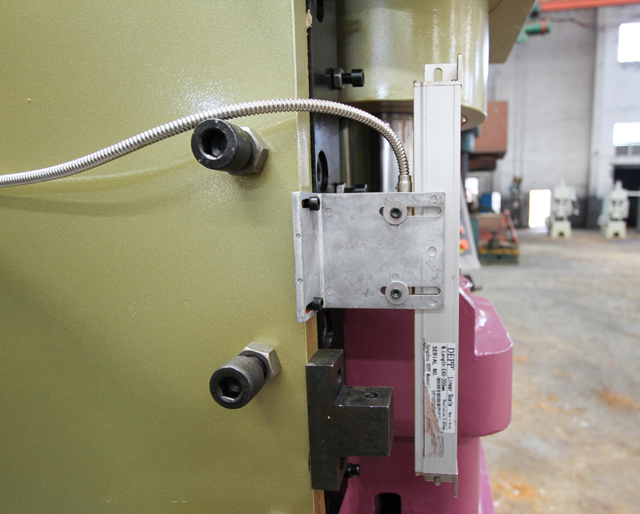

- Slider Stroke: 180 mm

- Max work pressure of liquid: 22.5 Mpa

- Slide working speed: 10-40 time /min

- Throat Depth: 310 mm

- Fast Speed: 210 mm/s

- Work speed: 14 mm/s

- worktable size: 850X600 mm

More Details

Products Description

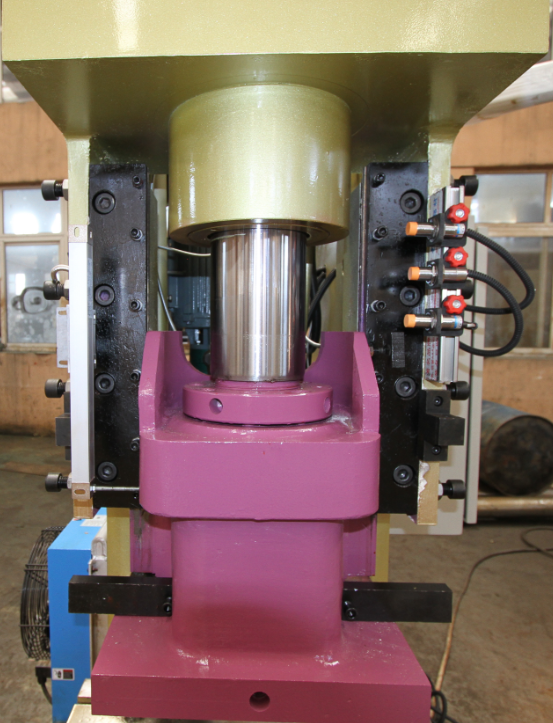

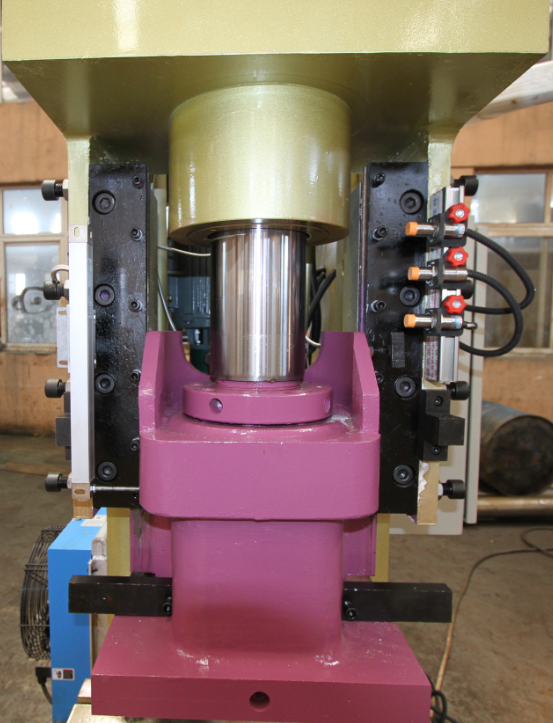

Y27Y series hydraulic fast press is suitable for punching, stretching and pressing of plastic materials, such as punching, bending, flanging of plate, stretching and fine punching of sheet metal, and cold extrusion of metal part. It may also be used for calibration, press-in, forming of grinding wheel, press forming of plastic products and powder products.

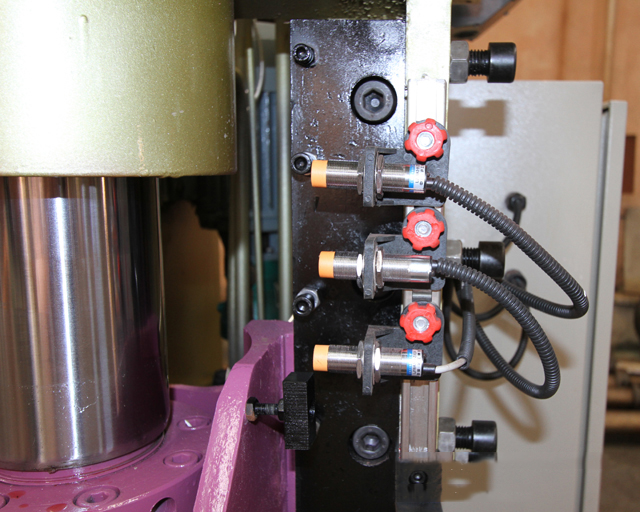

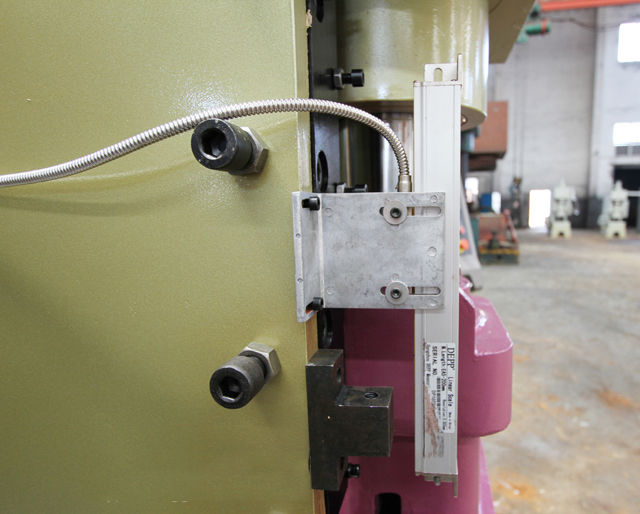

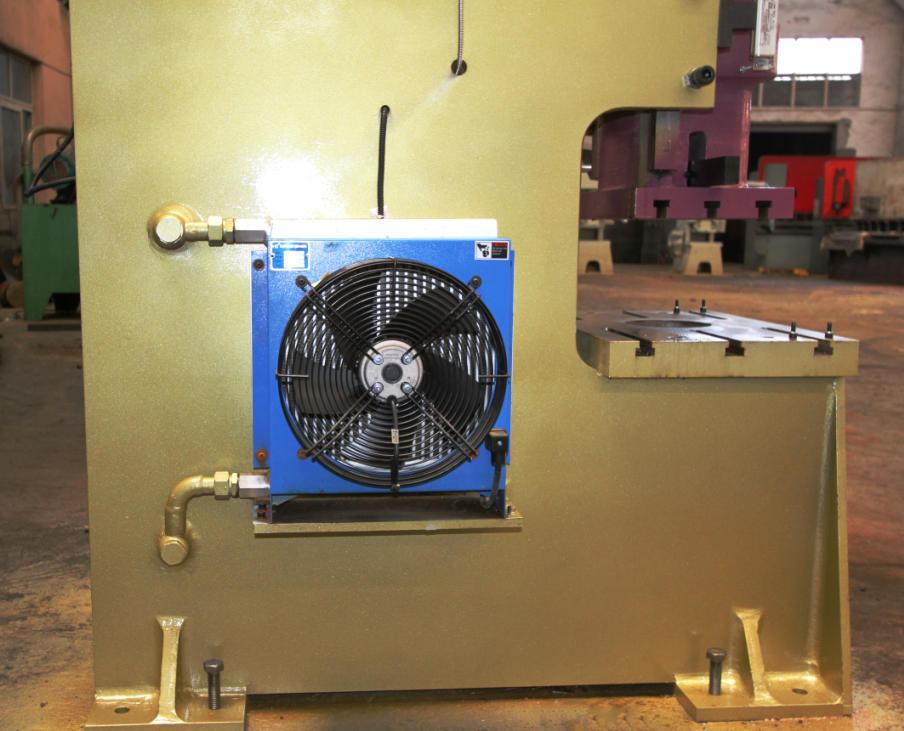

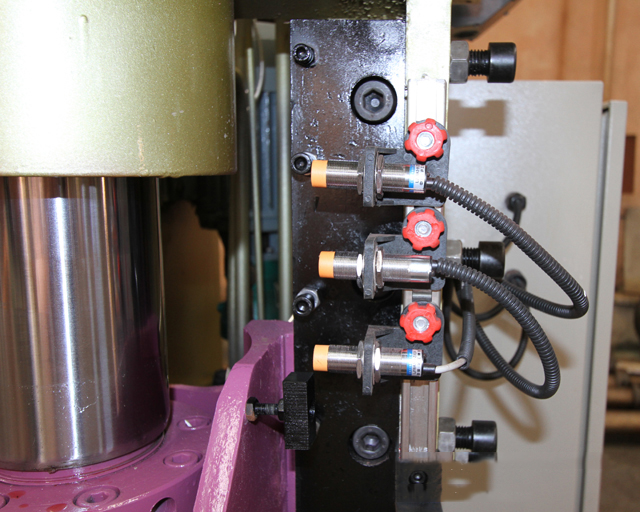

The machine uses hydraulic driving mode and has the advantages of a hydraulic press and a mechanical press. Pressing force of the machine can be changed at will. Over load will not occur in the machine. It can realize pressure keeping and time delay requirements during pressing. In order to realize slipper's quick downwards without load and quick back stroke, the machine adopts speeding-up oil cylinders. The machine began to operate automatically at a slow speed as it contacts a workpiece which decreases discharge capacity of an oil pump and motor power, and reduces noise. Photoelectric protection devices be installed in front of bench, which forms a protection screen on upper of the bench so as to protect operators. It uses centralized buttons, which may realize adjustment, semi-automatic and automatic operations. Therefore, the machine has the advantages of novel structure, reliable performance, a complete range of functions and high production efficiency, and it is a substituting product of a mechanical press.

Display

Speification

| Type | 50T | 63T | 80T | 100T | 125T | 160T | 200T | |

| Nominal pressure (KN) | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | |

| Stroke adjuster (mm) | 130 | 150 | 180 | 180 | 220 | 110 | 110 | |

| Slipper max.stroke (mm) | 130 | 150 | 180 | 180 | 220 | 220 | 220 | |

| Max.closing height (mm) | 320 | 445 | 470 | 170 | 550 | 520 | 520 | |

| Slipper work times (1/min) | 10-15 | 10-40 | 10-40 | 10-40 | 10-30 | 10-30 | 10-30 | |

| Speed to quickly move downwards (mm/s) | 220 | 220 | 220 | 210 | 250 | 230 | 230 | |

| Work speed (mm/s) | 14 | 18 | 17 | 14 | 16 | 10 | 10 | |

| Back stroke speed (mm/s) | 118 | 195 | 195 | 165 | 200 | 170 | 170 | |

| Throat depth (mm) | 235 | 260 | 310 | 310 | 350 | 350 | 400 | |

| Motor power (kw) | 5.5/4 | 5.5/4 | 5.5/4 | 7.5/6 | 11/6 | 22 | 22 | |

| Slipper under side size | Left and right (mm) | 320 | 440 | 500 | 500 | 600 | 600 | 700 |

| Front and back (mm) | 270 | 320 | 400 | 400 | 500 | 500 | 580 | |

| Die hole (mm) | Φ50 | Φ50 | Φ60 | Φ60 | Φ60 | Φ60 | Φ65 | |

| Bench size | Left and right (mm) | 630 | 710 | 850 | 850 | 1000 | 1000 | 1300 |

| Front and back (mm) | 450 | 500 | 600 | 600 | 650 | 650 | 740 | |

| Die hole (mm) | Φ150 | Φ1560 | Φ180 | Φ180 | Φ200 | Φ200 | Φ65 | |

| Machine Dimensions | Left and right (mm) | 1100 | 1250 | 1370 | 1350 | 1600 | 1700 | 1800 |

| Front and back (mm) | 1260 | 1450 | 1630 | 1630 | 1850 | 2000 | 2100 | |

| Height (mm) | 1980 | 2270 | 2500 | 2500 | 3400 | 3500 | 3600 | |

Application

This series of hydraulic presses are suitable for various stamping processes such as secondary stretch forming, bending, forming, blanking, and flanging of thin metal sheets, to meet the pressing of multi-planar complex structures, and are especially suitable for the following fields:

Auto parts: body cover, brake pads, fuel tank, chassis, axle housing, bumper;

Household appliances: washing machine parts, rice cooker parts: TV parts, refrigerator parts, etc.;

Kitchen appliances: sinks, pots, stainless steel appliances, other containers;

Others: tractors, motorcycles, aerospace, aviation.

Company Profile

Anhui zhongrui machine manufacturing co;Ltd was build in 2002 and located in Bowang Special Economical Zone, Anhui province. It was registered RMB 0.21 billion ,occupy 120,000 square meter with more than 400 employees and is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experience engineers and designers, and making it is one of the largest manufactures of sheet metal fabricating machinery in China.We are dedicated to the R&D and manufacturing of medium or high -level processing equipments and press lines for punching ,shearing, bending and laser cutting of metal plates.

Zhongrui not only is the AAA level contracts and keep promise in enterprises, but also passes the ISO9001 certification and CE certification .With years of development and accumulation , we continued to strengthen research and development of new products , introduce the cnc technology which come from Italy and Germany. CNC press brake ,cnc fiber laser cutting machine that we produced have achieve a real sense of CNC automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers satisfaction, the company achieved a product with strict control from design, manufacture process, inspection until the whole machine delivery ,installation and service.Zhongrui will keep enterprising in the corporate spirit of "credit, collaboration, pragmatism and innovation" and Sincerely hope to make progress together and jointly create brilliance with friends of all circles

FAQ

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How do I operate this machine?Is training necessary?

A:The machine is mainly controlled by software.Simple, not complicated. Generally speaking, an operator who is not familiar with the press brake can still operate it well.According to customer requirements, we can send technicians to the customer's factory for machine training, or when the customer needs to come to our factory for machine training.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How about your machine quality?

A: We have approved the ISO9001:2008 Quality management system and Europe and American safety standard,including CE,GS,EMS and UL. Zhongrui is a mature brand in China, through our 13 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.

Q: Can you provide customized machine and tool?

A: Yes,we can design and manufacture according to user's specific requirements.