Quick Description

- Slider Stroke (mm): 220 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 320 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 3200 mm

- Width of Working Table (mm): 120 mm

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: RAYMAX

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: End Forming

- Year: 2022

- Weight (KG): 9800

- Motor Power (kw): 15 kw

- Key Selling Points: Competitive Price

- Warranty: 2 years

- Applicable Industries: Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Retail, Construction works , Energy & Mining, Advertising Company

- Showroom Location: United States, Italy, India, Spain, Thailand

- Marketing Type: New Product 2022

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Product name: automatic metal press brake

- Raw Material: steel

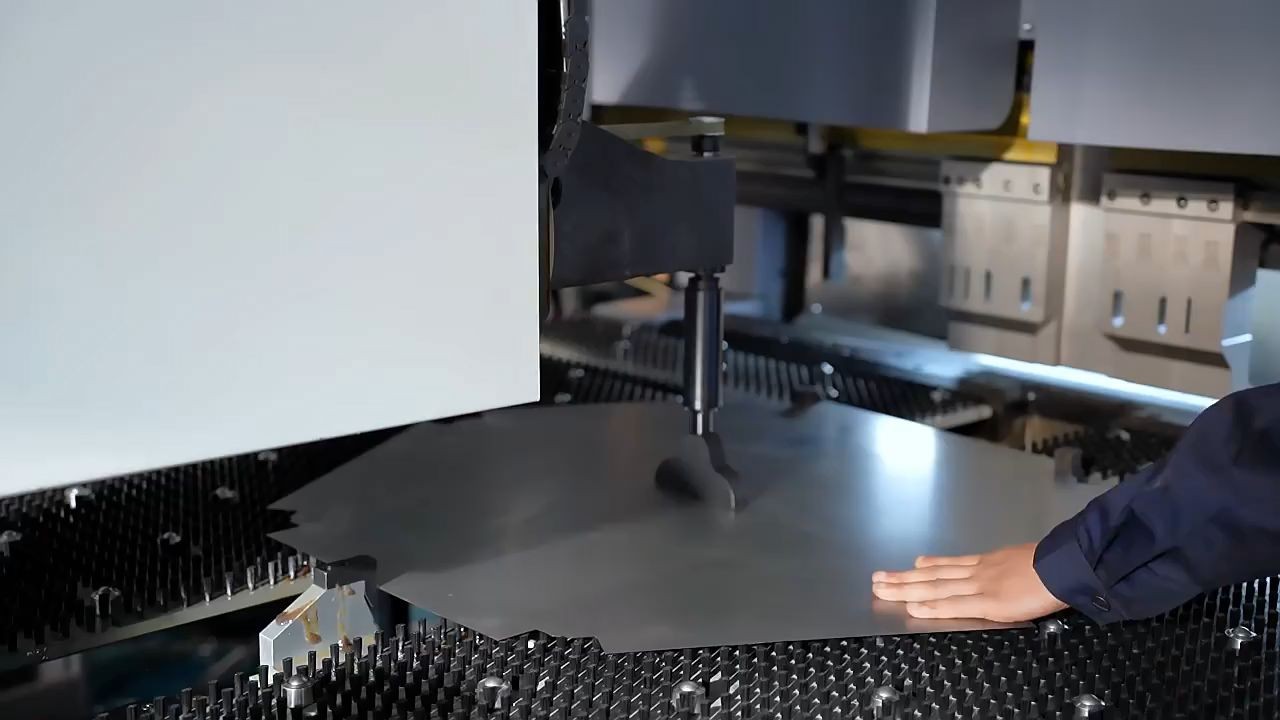

- Usage: Metal Sheet Bending

- poles distance: 2600mm

- Control system: DA41 DA56 DA66 Option

- slider travel: 120

- max open: 380mm

- Voltage: 220V/380V/415V/440V/customized

- Nominal Pressure (kN): 800 kN

- Certification: ce

More Details

Product Description

100T 125T 160T 200T 250T CNC press brake with delem controller DA66T

CNC series Electro hydraulic serve pump controller CNC press brake is of servo main motor which drives 2 way pump to control dual.

Oil cylinder synchronously mechanical (hydraulic)crowning compensation device is equipped

The press brake features energy saving by 50%, oil volume saving by 70% compared with traditional hydraulic press bake

Multi backgauge axes are available steel weld machine frame gets annealing treatment with constant accuracy Netherlandish DELEM DA66T.

| Product | CNC hydraulic press brake |

| Backgauge axes | 3 1Axis /4 1Axis /5 1Axis /6 1Axis/7 1Axis/8 1Axis /10 1Axis |

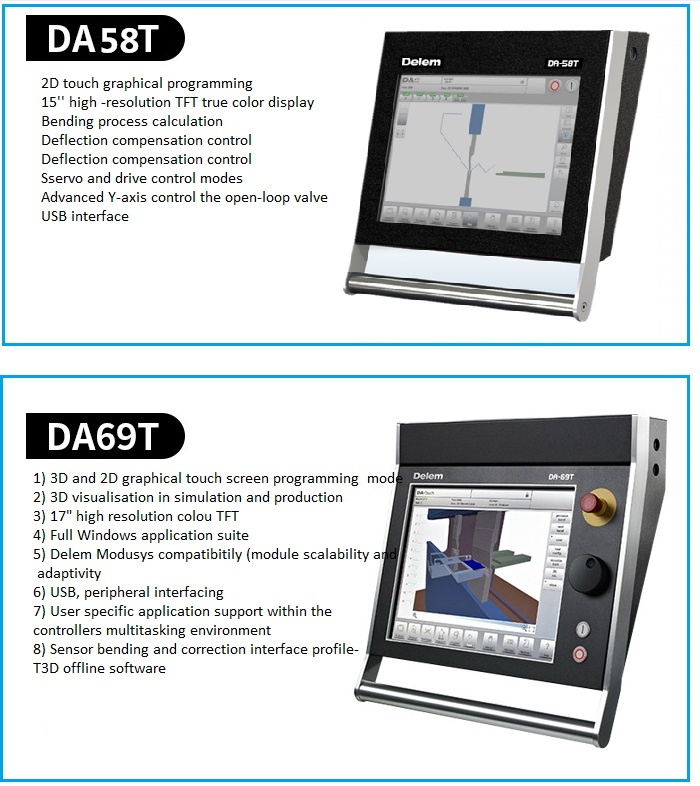

| Optional controller | DA52S/DA66T/DA69T |

| Bending material | Carbon steel、Stainless steel、Aluminum、galvanized steel 、Iron and etc. |

Detailed Images

Double structure front arm

Double structure is higher rigidity ,superior carrying capacity .It can be adjusted up and down or move along the workbench from side to side

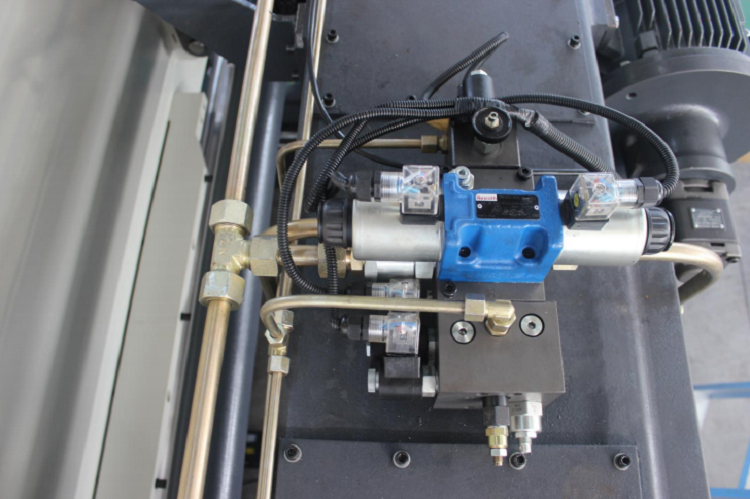

* Adopt integrated hydraulic control system, more reliable and easy for maintenance.

* Reduced noise: the particular installation choices allow to obtain especially moderate noise levels both on machines of average capacity

* Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level can be read or seen directly.

The hydraulic system is made in compliance with current regulations

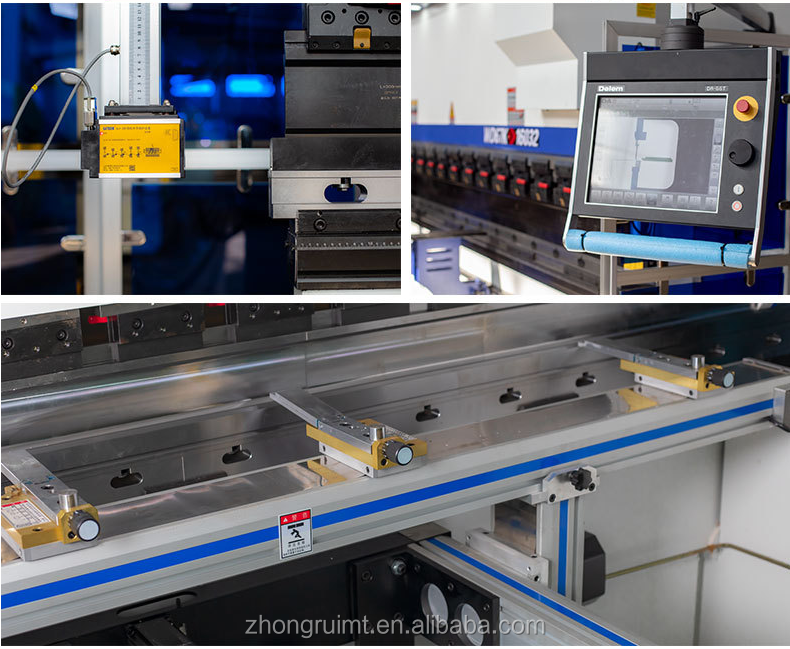

Delem DA66T

*2D graphical touch screen programming mode

* 3D visualisation in simulation and production

* 17" high resolution colour TFT

* Full Windows application suite

* Delem Modusys compatibility (module scalability and adaptively)

* USB, peripheral interfacing

* User specific application support within the controllers multitasking environment

* Sensor bending & correction interface

* Profile-TL offline software

Grating ruler

Incremental or absolute ruler based on optical or magnetic techniques for synchronous bending machines.

The reader is guided by a self-aligning and self-cleaning slider with a spring system.

The resolution can be up to 0.1 micron. Accuracy up to ±1 micron.

Grating or tape with a specific linear thermal expansion coefficient.

Magnetic zero position device with reference to coding distance or optional every 10 mm along the entire length of measurement.

Safety limit switch, positioned at both ends.

Adjustable output cable position and optional zero reference index make the ruler symmetrical and suitable for bending machine two columns.

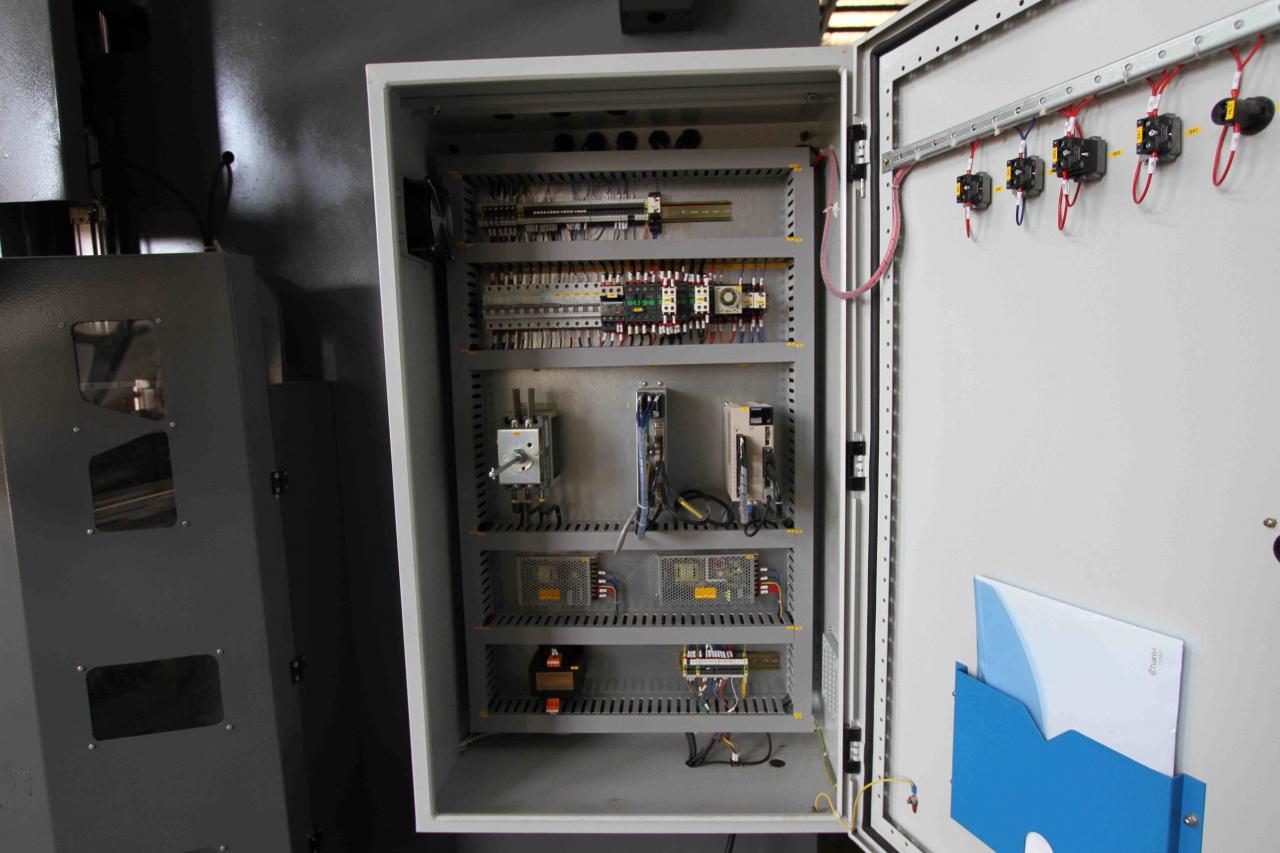

French Schneider Electric components with frequence Inverter

*High quality electric parts can perform well even the electricity is not stable and customers

*can easily get the replacement anywhere in the word

*The motor for backgauge stroke are controlled by inverter, which can achieve high positioning accuracy of the backgauge

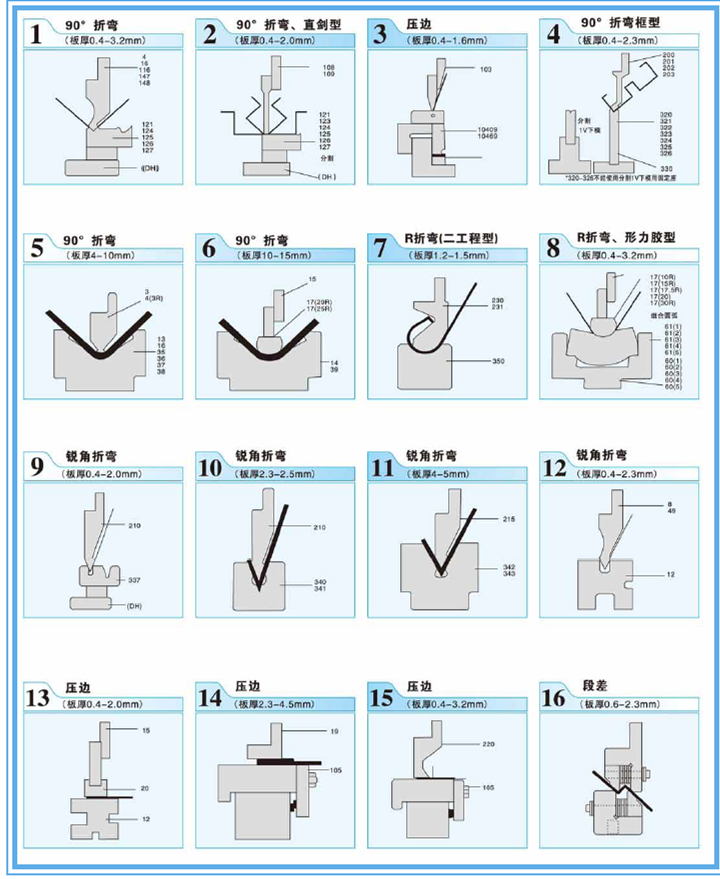

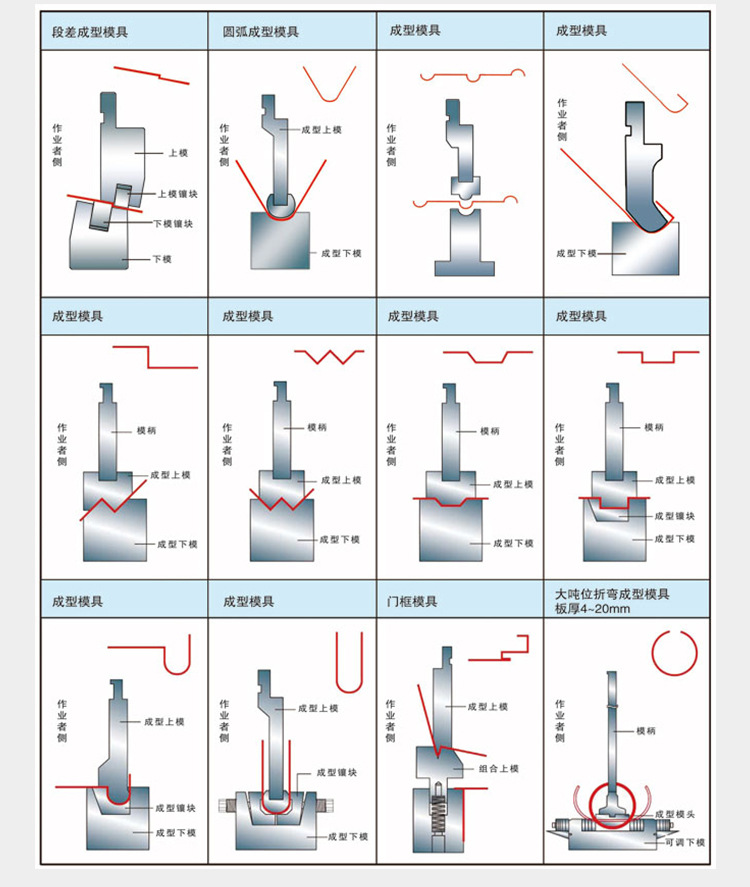

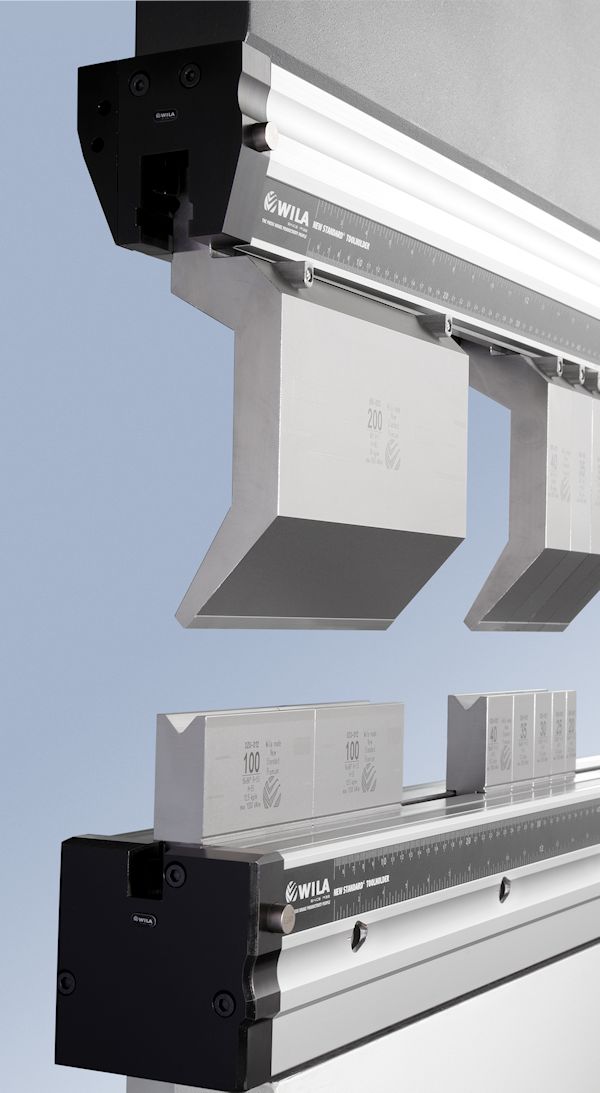

optional

Technical

Certificate

Company Introduction

Anhui zhongrui machine manufacturing co;Ltd was build in 2002 and located in Bowang Special Economical Zone, Anhui province. It was registered RMB 0.21 billion ,occupy 120,000 square meter with more than 400 employees and is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experience engineers and designers, and making it is one of the largest manufactures of sheet metal fabricating machinery in China.We are dedicated to the R&D and manufacturing of medium or high-level processing equipments and press lines for punching ,shearing, bending and laser cutting of metal plates. Zhongrui not only is the AAA level contracts and keep promise in enterprises, but also passes the ISO9001 certification and CE certification .With years of development and accumulation , we continued to strengthen research and development of new products , introduce the cnc technology which come from Italy and Germany. CNC press brake , cnc fiber laser cutting machine that we produced have achieve a real sense of CNC automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers satisfaction, the company achieved a product with strict control from design, manufacture process, inspection until the whole machine delivery ,installation and service.Zhongrui will keep enterprising in the corporate spirit of "credit, collaboration, pragmatism and innovation" and Sincerely hope to make progress together and jointly create brilliance with friends of all circles

FAQ

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How do I operate this machine?Is training necessary?

A: The machine is mainly controlled by software.Simple, not complicated.Generally speaking, an operator who is not familiar with the press brake can still operate it well.According to customer requirements, we can send technicians to the customer's factory for machine training, or when the customer needs to come to our factory for machine training.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How about your machine quality?

A: We have approved the ISO9001:2008 Quality management system and Europe and American safety standard,includCE,GS,EMS and UL . Zhongrui is a mature brand in China, through our 13 years research in technology,our design including structure and detailed security and precision has enhanced greatly, and can match all the CE standard or more strict standard.

Q: Can you provide customized machine and tool?

A: Yes,we can design and manufacture according to user's specific requirements