Quick Description

- Slider Stroke (mm): 80 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 200 mm

- Machine Type: Torsion Bar

- Length of Working Table (mm): 1600

- Width of Working Table (mm): 600 mm

- Dimension: 1600X1150X1780

- Condition: New

- Place of Origin: Anhui

- Brand Name: Raymax

- Material / Metal Processed: Stainless steel, Carbon steel

- Weight (KG): 1300

- Motor Power (kw): 3 kw

- Key Selling Points: High Safety Level

- Warranty: 1 Year

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

- Showroom Location: Egypt, France, Germany, Philippines, Spain, Colombia, Algeria, Sri Lanka

- Marketing Type: New Product 2022

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

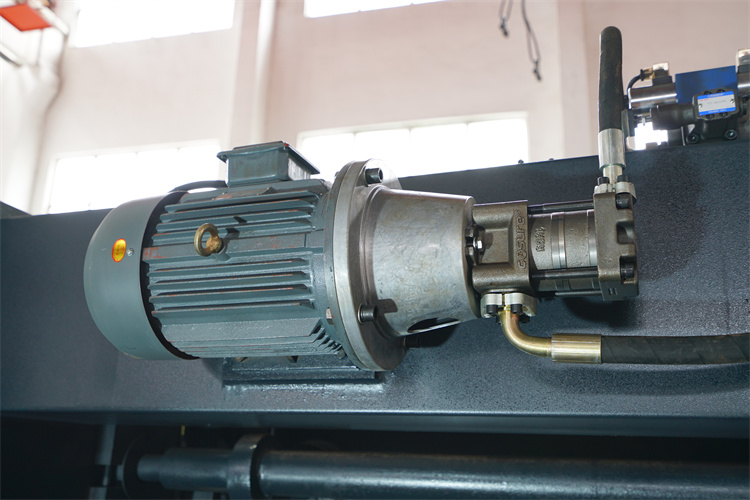

- Core Components: Motor, Pump, Other

- After-sales Service Provided: Online Support

- Type: Hydraulic Bending Tools

- Color: Customer Choose

- Keyword: Hydraulic Press Break

More Details

Products Description

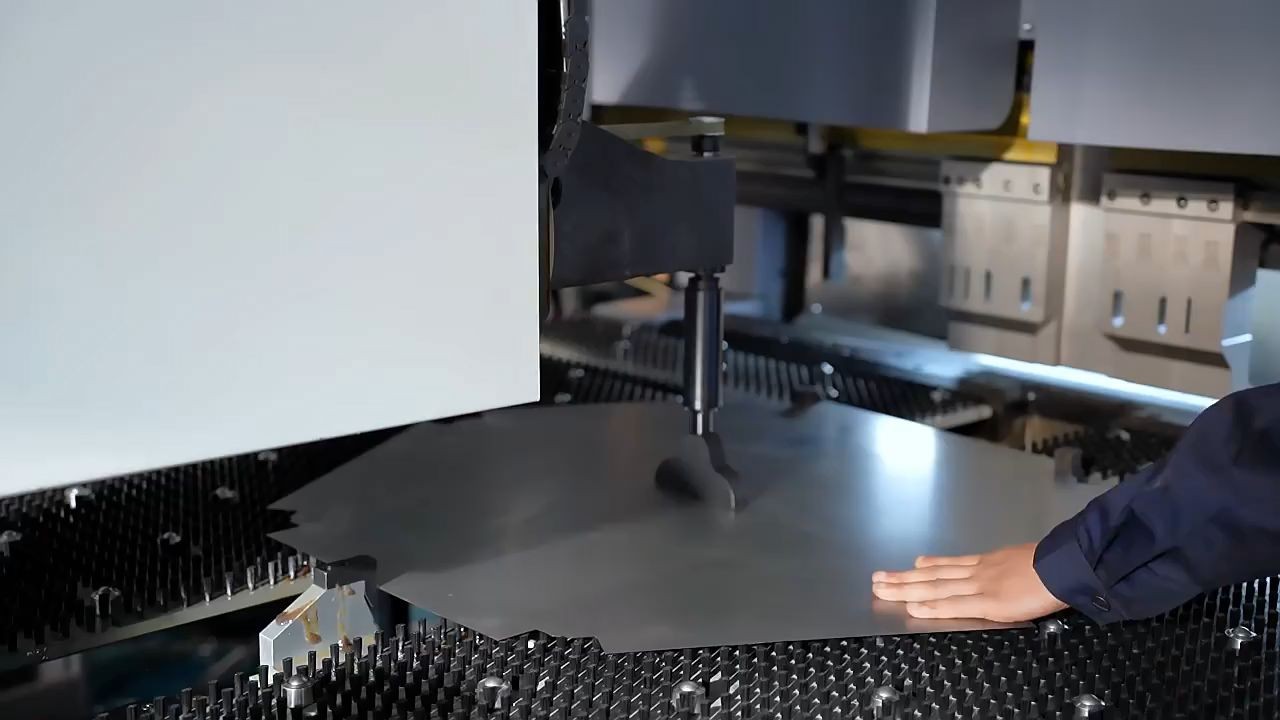

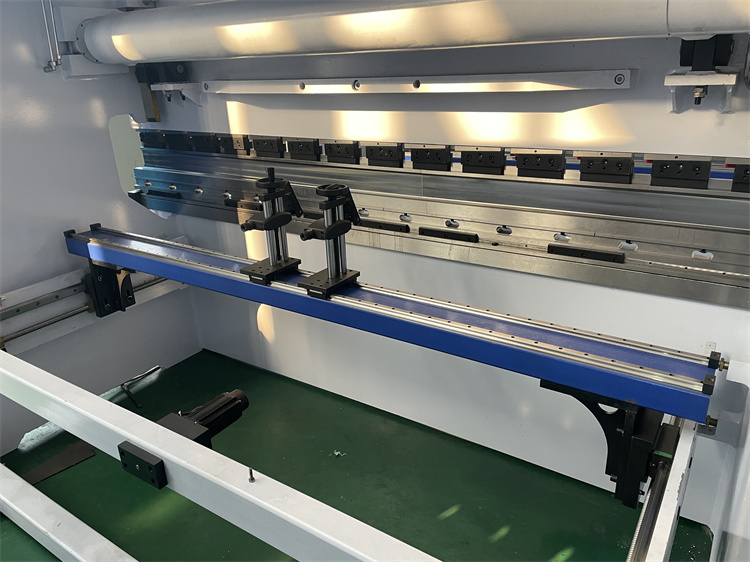

Hydraulic Sheet metal Folder and NC Press Braking Machine

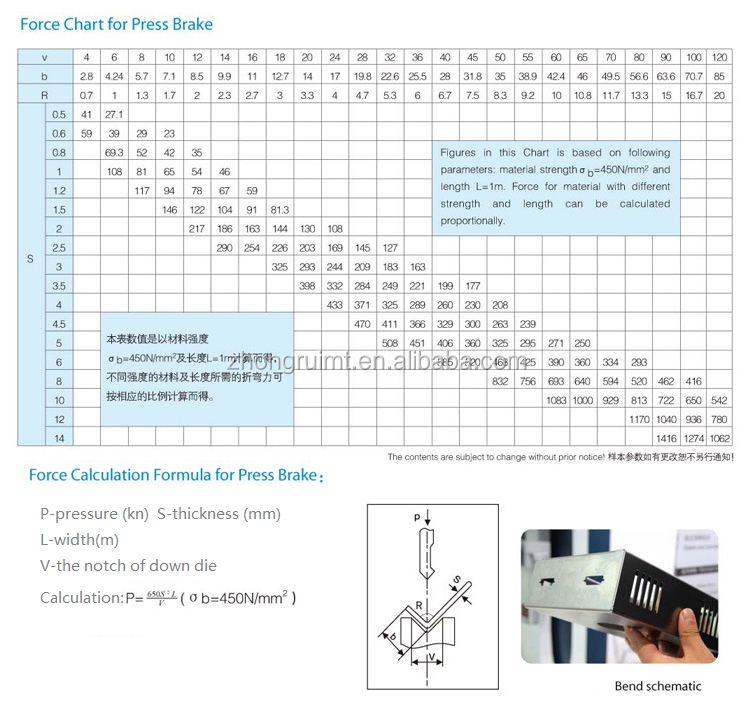

Bending machine is the use of the mold (general or special mold) to bend the cold metal sheet into various geometric sections of the workpiece.

1. The main mechanical structure of a machine tool is composed of frame, column, slider, worktable, main cylinder, back carrier and other parts. Through finite element analysis and optimization design by three-dimensional software, the structure strength and rigidity of each main component can be fully ensured .

2. Internal stress of welded parts can be eliminated by tempering and vibration aging.

3. The oil cylinders fitted on both sides adopt closed loop control mode which is composed of Germany electro-hydraulic servo valve and imported grating ruler, breaking through the stroke control mode of traditional mechanical stop bending machine ,ensuring the high precision of the glide position, the accurate and stable operation, the high precision of bending

Main Features

1. Totally EU streamlined design, Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2. Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany,

3. Mechanical synchronous mechanism and the complex compensation are designed so as to raise the workpieces precision.

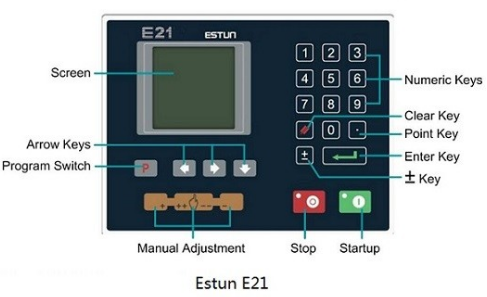

4. The stroke and distance of the backgauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by E21.

5. Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays.

6. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

| Working Source | Hydraulic |

| Bending Material | Carbon steel, stainless steel, aluminum, mild steel |

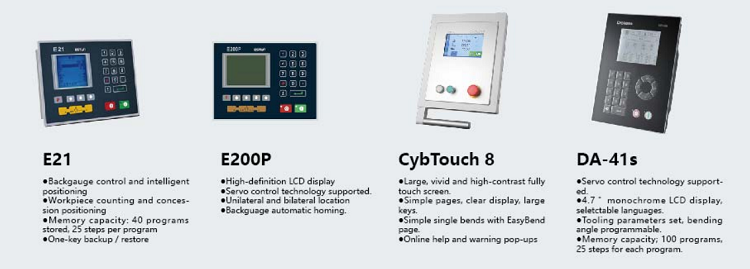

| Controller | NC Controller, E21, E220P, DA41, CT12 |

| Press Brake Usage | Bending plate into different AngleCurling Plate into Hinge Flattening plate |

| Voltage | 220V/380V according to customer request |

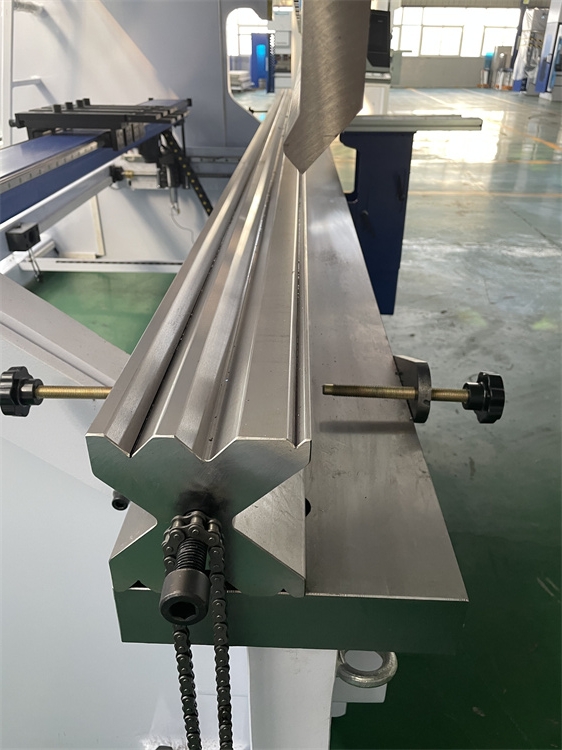

| Tooling | A set of standard tooling |

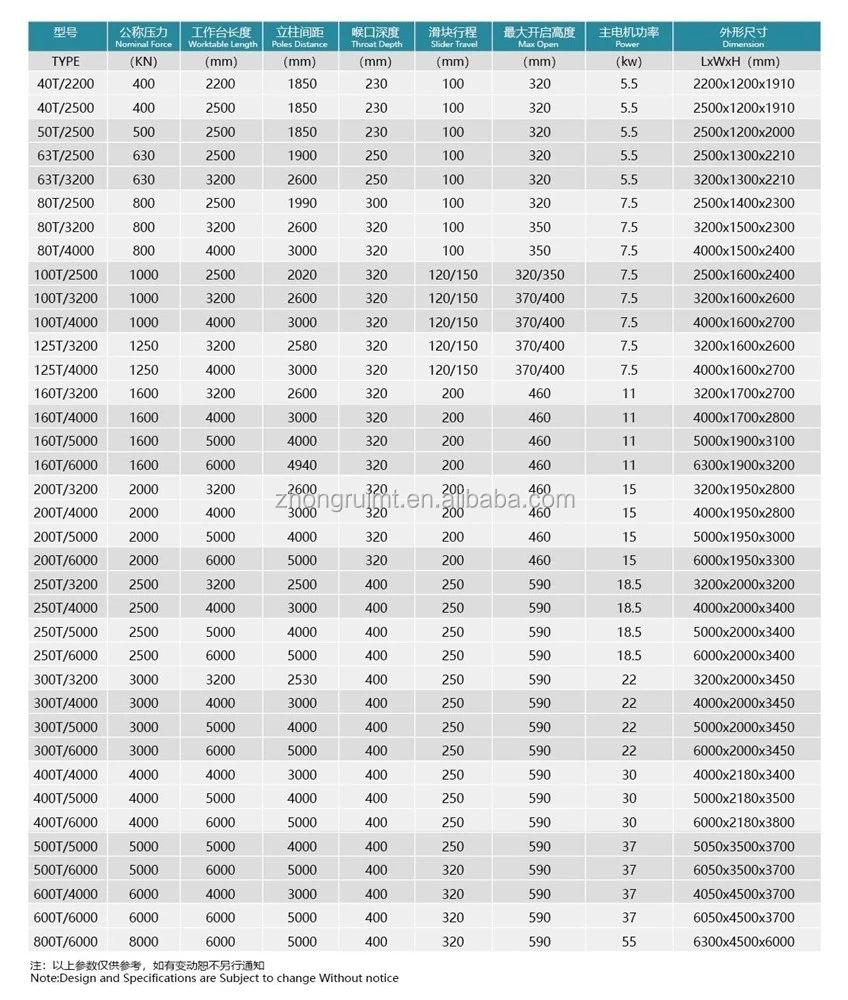

Speification

Configuration

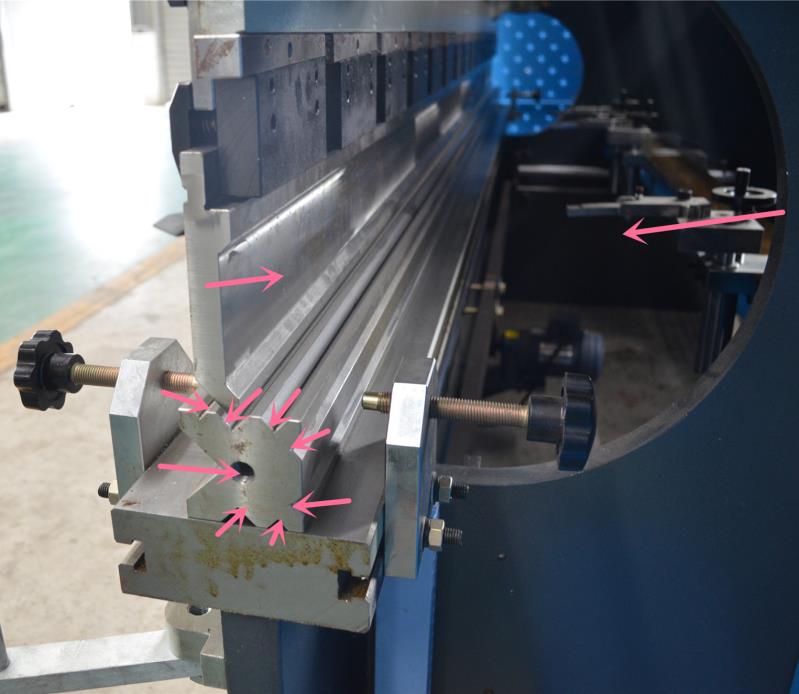

Quick clamp

1. The mold can be installed and removed to the left and right when pull the red handle

2. The mold can be installed up and down when press the button

3. scale more accuracy

Electric cabinet

Siemens or Schneider world famous brand

Electrical system Our press brake adopts Schneider electrical components. The high quality electric parts can make the machine performing well even the electricity is not stable and customers can easily get the replacement

Front finger Protection

The height of the finger can be adjusted manually: the height of the finger is designed by the overall adjustment, and the height of the finger can be manually adjusted.

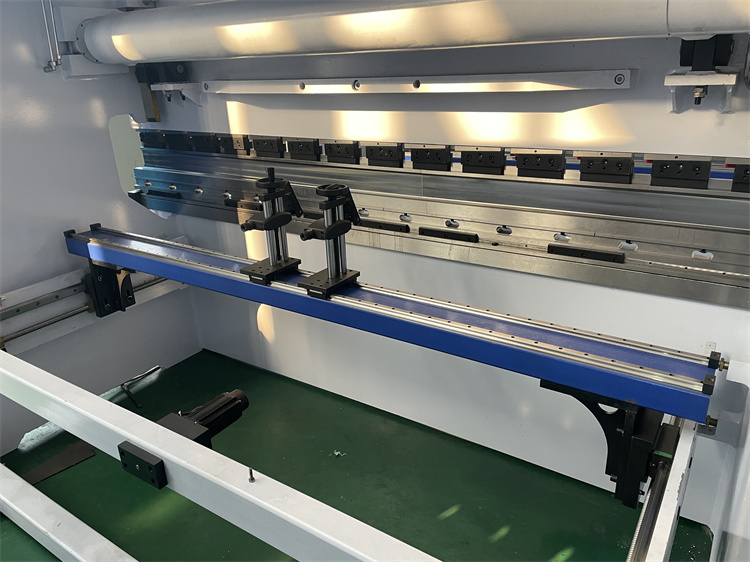

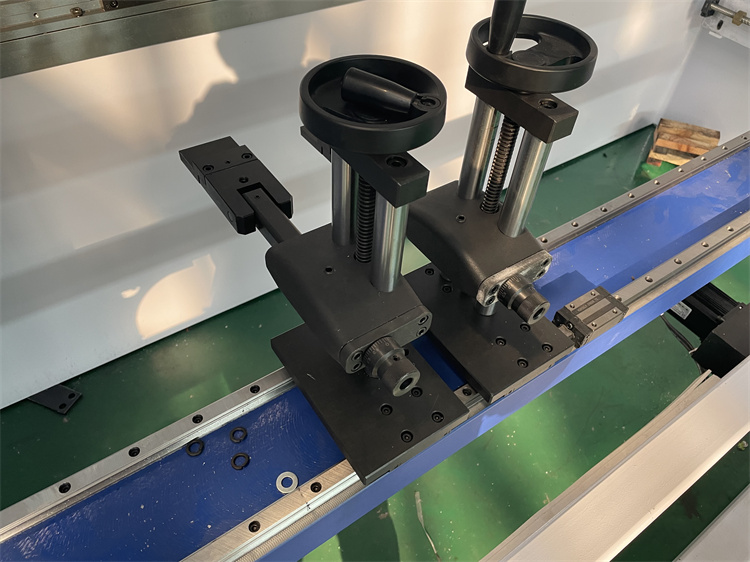

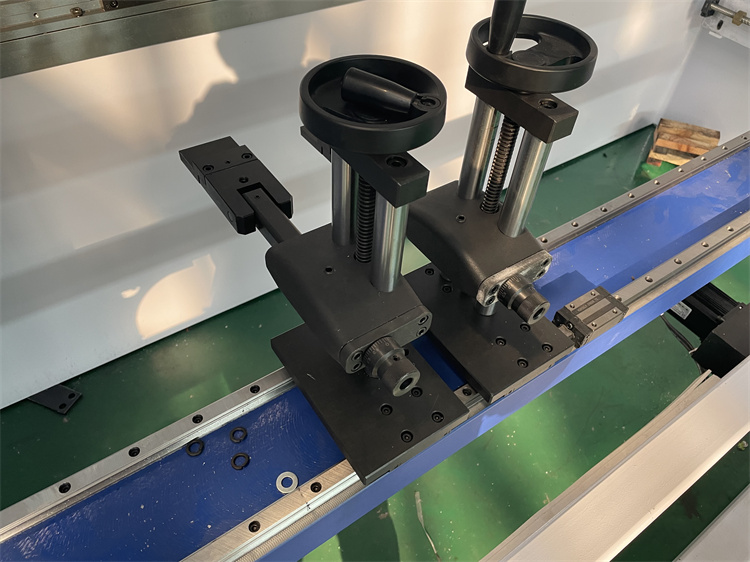

Backgauge

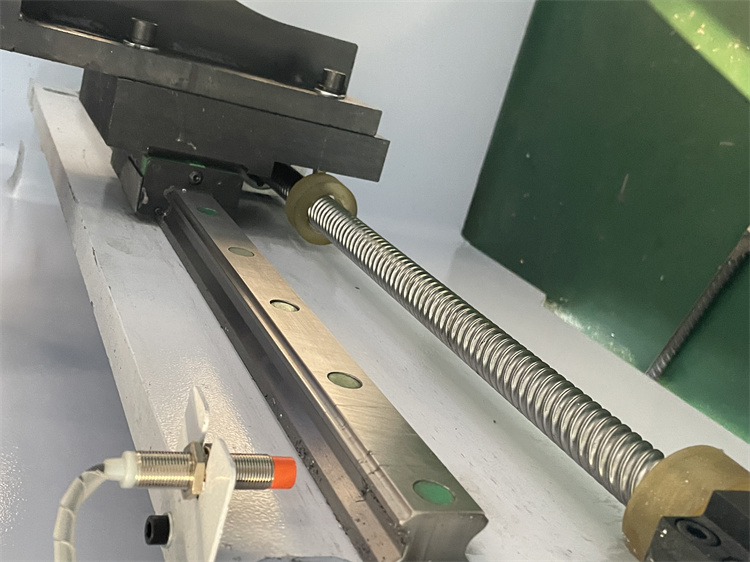

It is made of high-strength aluminum alloy material, driven by servo motors,and uses ball rods and linear guide rails, with good positioning accuracy

Full envelope design free of maintenance

Front Plate Support

Movable front material support on linear guider can move left and right by hand very easy.

Ball Screw & Linear Guide

Adopting HIWIN ball screw and linear guide to improve the machine backguage accuracy.

Germany Siemens Motor

Using Siemens motor guarantee the machine service life and improve the machine working stability.

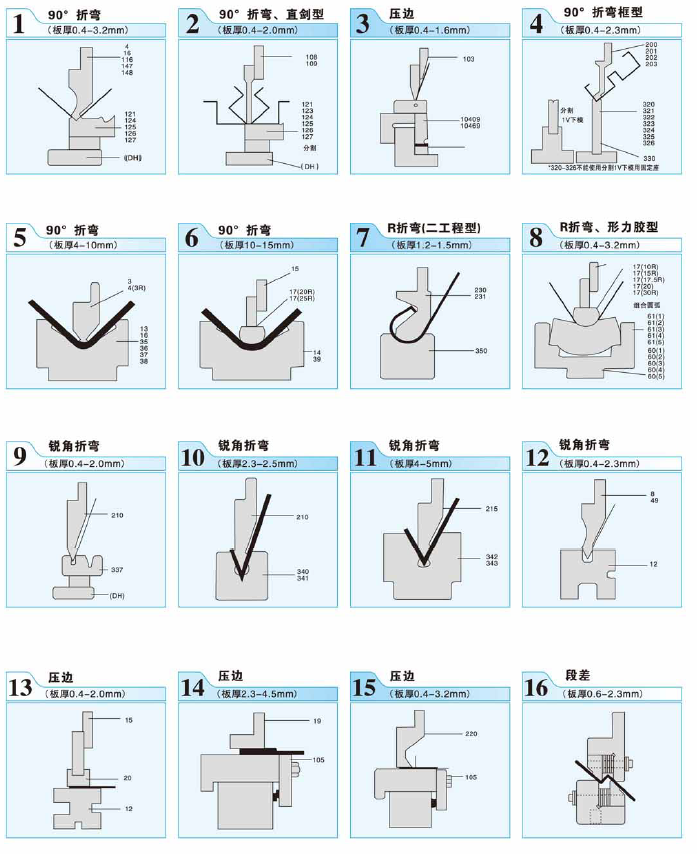

Press Brake Toolings

The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use.

E21 control system

● Monochrome LCD Box Panel.

● Integral factor programmable freely

● Automatic positioning control

● Spindle allowance offset

● Internal time relay

● Stock counter

● Backgauge position display, resolution in 0.05mm

Application

The folded sheet metal bending machine has high productivity and high working accuracy, using different shapes of up and down mould, can be bent into various shapes artifacts, slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending can be achieved relatively complex shape workpiece, when equipped with the corresponding equipment, can also make a punch.

Equipment

●Estun E21 NC control System

●Powered Depth Y-axis & Back gauge X-axis

●Schneider Inverter controlled back gauge

●HIWIN Ball screws & Polished rod with 0,05 mm accuracy.

●Plate Support Arms

●Germany Bosch-Rexroth Hydraulic

●Germany EMB Tubing connector

●Germany Siemens Main Motor

●Telemecanique/Schneider Electrics

● Hydraulic & Electrical overload protection

●Top and Bottom Tooling(86°, R0.6mm)

Company Profile

Anhui zhongrui machine manufacturing Co;Ltd was build in 2002. It is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experienced engineers and designers, which makes it be a well-known brand of sheet metal fabricating machinery in China.

We are a modernized machine tool factory which is dedicated to the development, production and sales of sheet metal equipment with history over than 20 years. The factory mainly specializes in press brake, shearing machine, hydraulic press machine, fiber laser cutting machine and punching machine. Professionally provide complete sets of metal sheet and profile processing machinery for automobiles, ships, railways, aviation, electric power, petrochemicals, light industry and other industries; products are sold all over the country and exported to Southeast Asia, Middle East, Western European, South America and other regions.

We have passed the I S O 9 0 0 1 certification and C E certification. We continued to strengthen research and development of new products, introduce the c n c technology which comes from Italy and Germany. C N C press brake, C N C fiber laser cutting machine that we produced have achieved a real sense of C N C automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers’ satisfaction, we have realized strict control of products from design, manufacturing process, inspection to complete machine delivery, installation and service.