Quick Description

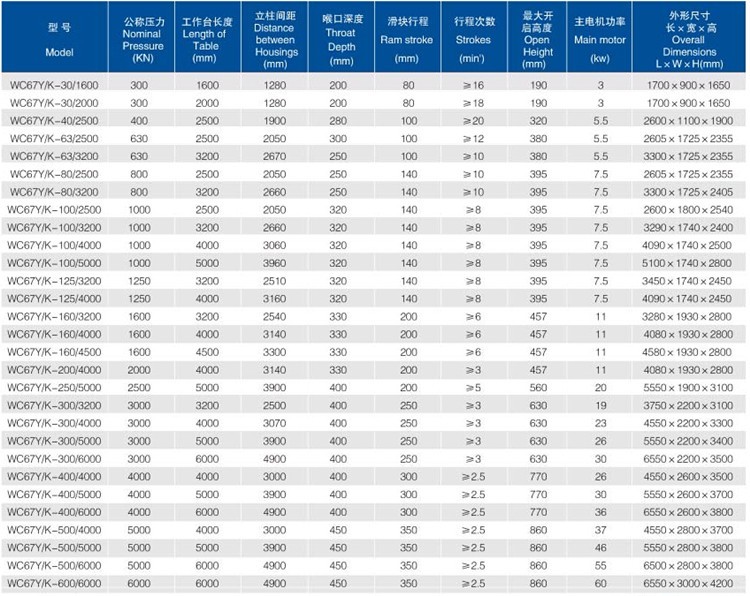

- Slider Stroke (mm): 140 mm

- Automatic Level: Semi-automatic

- Throat Depth (mm): 250 mm

- Machine Type: Synchronized, Press Brake

- Length of Working Table (mm): 3200 mm

- Width of Working Table (mm): 3200 mm

- Dimension: 3200*1300*2300 MM

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum, Plastic

- Automation: Automatic

- Extra Services: End Forming

- Year: 2020

- Weight (KG): 5600

- Motor Power (kw): 7.5 kw

- Key Selling Points: Competitive Price

- Warranty: 5 years

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Canada, Russia, Chile

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Other, Gearbox

- After-sales Service Provided: Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Power: Hydraulic

- Raw Material: Steel Bar

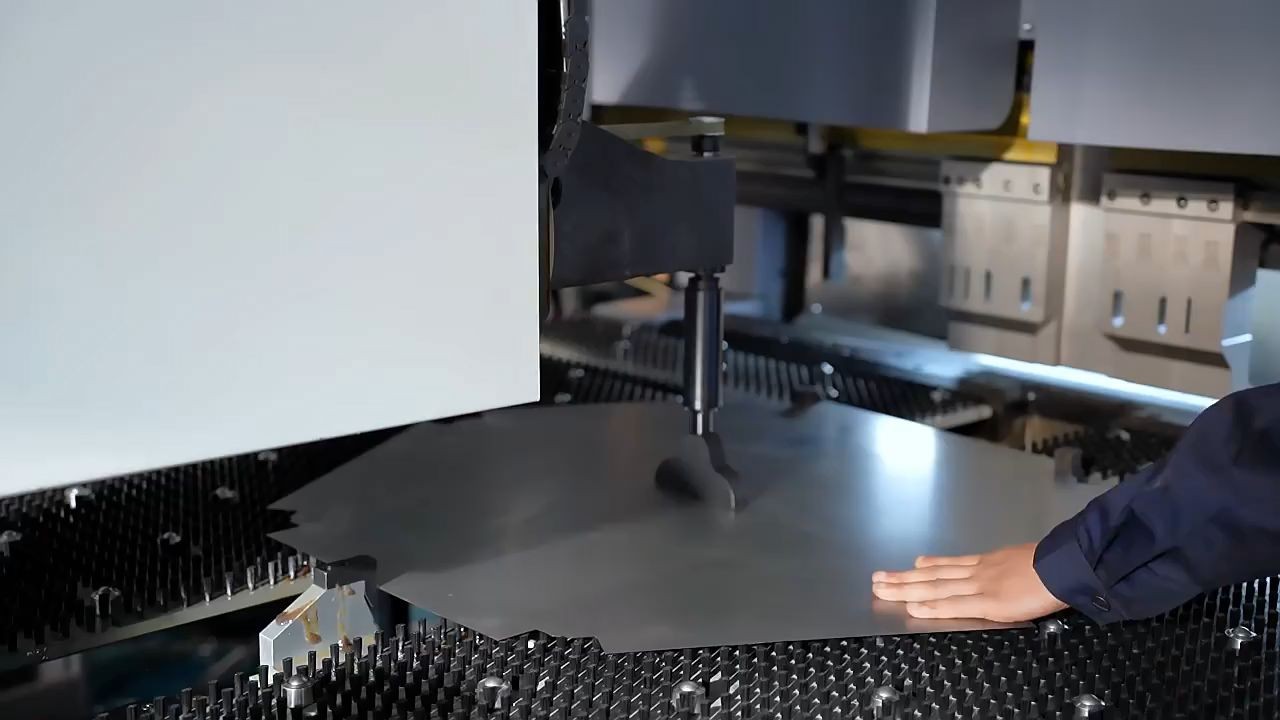

- Name: Simple digital display bending machine

- Color: Customized

- Material: Steel

- Application: steel sheet plate

- Usage: Metal Sheet Bending

- Voltage: 220V/380V/415V/440V/customized

- Certification: ISO 9001:2000

- After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

More Details

1. Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating toeliminate stress, high strength and good rigidity.

2. Mechanical torque system makes sure the synchronization of cylinders.

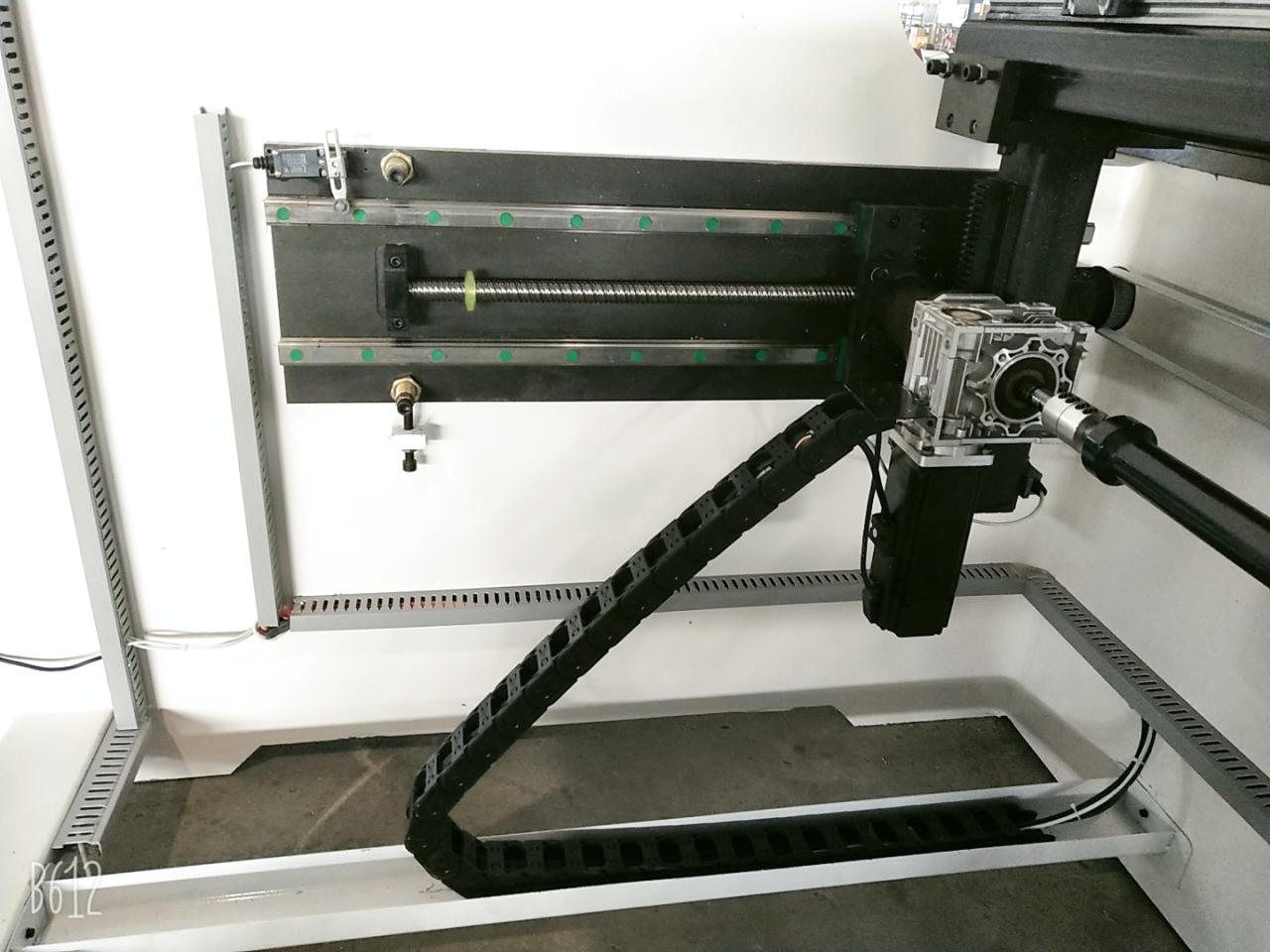

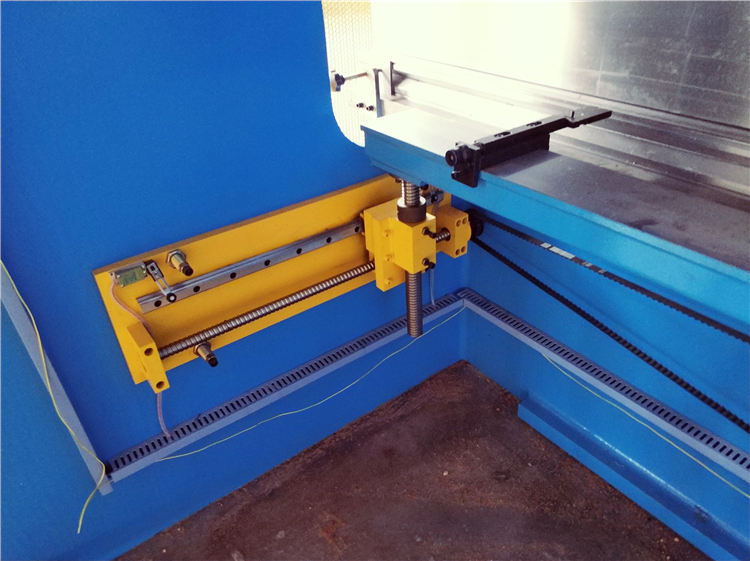

3. The stroke of slider and back gauge is adjusted automatically by double servo motors or transducer, and showed on CNC Mechanical torque or NC control panel.

4. Slanting wedges can be chosen to install on the top dies which can be adjusted by hands or automatically. Hydraulic compensation system is installed under the worktable.

Detailed Images

Bending tools can customization accroing to your drawing

Motor- Siemens (Germany ) or Sangta (Anhui)

Electrical-Schneider(France)or CHNT(China)

Ball screw and Linear guide-HIWIN (Taiwan)

Oil seal- NOK (Japan)

Backague

Package

Normal package is plastic, for machine safety, we suggest that customers use wooden case for packaed machine.

We can give you best and suitable shipment ways. We have a professional documentation department to help customers solve import problems and provide a complete set of customs clearance documents