Quick Description

- Max. Cutting Width (mm): 2500

- Max. Cutting Thickness (mm): 6 mm

- Automatic Level: Fully Automatic

- Shearing Angle: 1.5

- Blade Length (mm): 2600 mm

- Throat Depth (mm): 125 mm

- Condition: New

- Brand Name: Raymax

- Power (kW): 7.5 kW

- Weight (KG): 4600 KG

- Place of Origin: Anhui, China

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Applicable Industries: Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Food Shop, Printing Shops, Construction works

- Showroom Location: United States, Italy, France, Germany, India, Spain

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Bearing, Motor, Pump, Gear, Pressure vessel

- Application: Industrial Metal Cutting

- Color: Customer Selected

- After-sales Service Provided: Video Technical

- Control system: E21S/ELGO P40/E200PS/DAC360

- Cutting mode: Hydraulic Metal Cutting

More Details

Feature

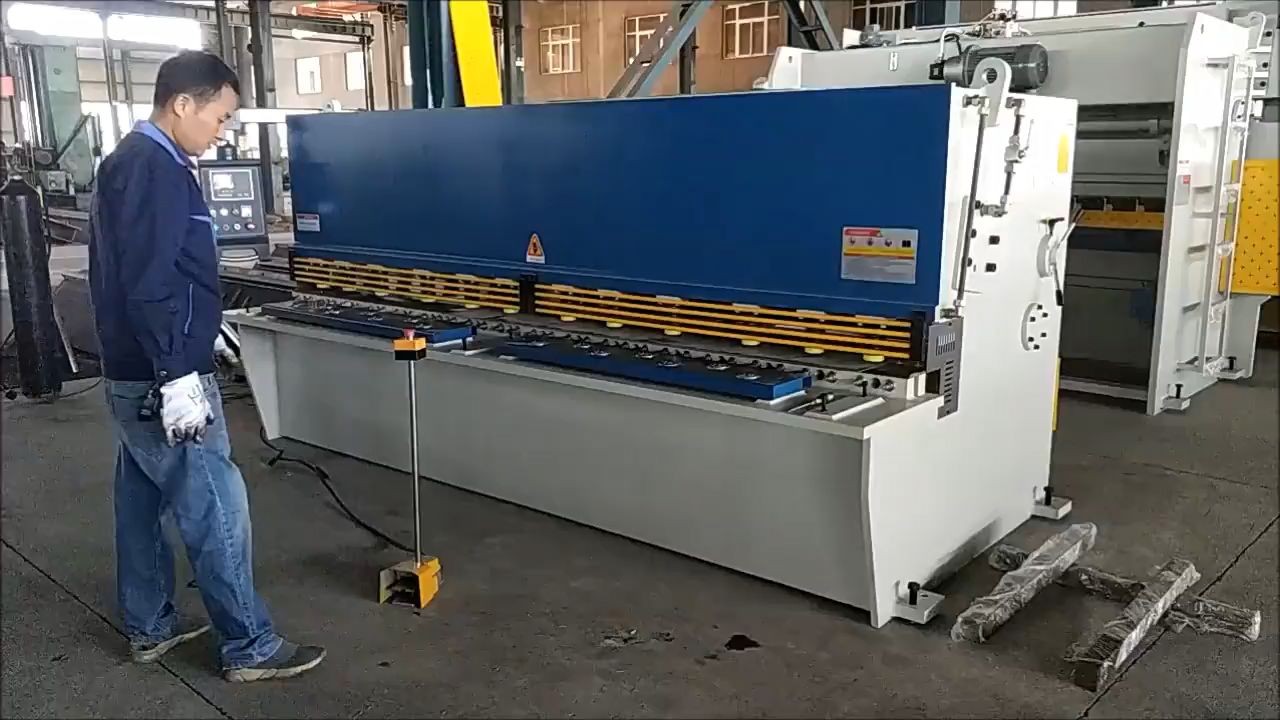

QC12Y series NC hydraulic shearing machine consists of frame, blade, rear stop, rapid blade, gap adjustment mechanism, hydraulic system, electrical system components, racks welded by right and left wall board and upper and lower support block. After eliminate stress to ensure the rack has sufficient rigidity and strength.

Both of sides wall board had two cylinders, blade install on right and left wall board, Under the hydraulic system, drive blade to do swing arc action. On blade racks, there are upper blade, shear with lower blade which on work table. Upper blade surface is arc surface, ensure consistency when shear the plates. To ensure the quality of the workpiece cutting. The great advantage of the machine is convenient and quick.

Rear stop used for supporting, screw gauge beam driven and do forward and backward action, has high precision.

●The machine employs hydraulically-driven swing beam, the steel plate welded structure, and accumulator-based pullback cylinder with steady and reliable operation.

● Indicator-based adjustment of gap of blade is convenient and fast.

● The machine is equipped with lighting alignment device, and uses stepless control for the stroke of up tool carrier.

● The machine uses protection fence for safe operation.

● Digital display device for size of back gauge and shearing times available.

Display

Standard Configuration

●Estun E21

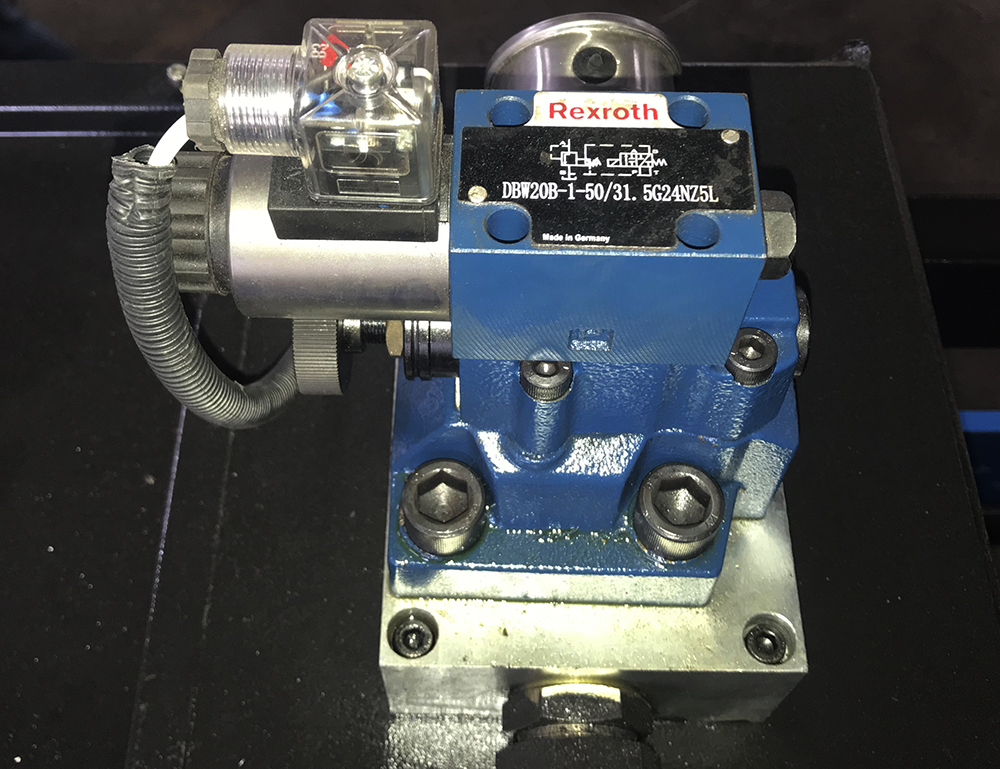

●Hydraulic System Bosch Rexroth from Germany

●Sunny pump

●Main Motor Germany Siemens Brand

●Electric Schneider of France

●Kacon foot switch

●EMB Tube

●Ball Screw hiwin taiwan Polish Rod

●Stroke Motor KUNGTE

●Seal ring :NOK JAPAN

● Oil tank with oil gauge

●Safety fences

Parameter

| Model | Cutting thickness (mm) | Cutting length (mm) | Cutting Angel (°) | Stopper Adjust Range (mm) | Stroke time (min-1) | Motor (KW) | Dimension(mm) | Weight(t) |

| QC12Y-4X2500 | 4 | 2500 | 1.5 | 500 | 18 | 7.5 | 2900x1500x1580 | 3.1 |

| QC12Y-4X3200 | 4 | 3200 | 1.5 | 500 | 14 | 7.5 | 3580x1500x1580 | 5.2 |

| QC12Y-4X4000 | 4 | 4000 | 1.5 | 500 | 12 | 7.5 | 4480x1500x1580 | 6.7 |

| QC12Y-6X2500 | 6 | 2500 | 1.5 | 500 | 18 | 7.5 | 2990x1650x1620 | 4.6 |

| QC12Y-6X3200 | 6 | 3200 | 1.5 | 500 | 14 | 7.5 | 3690x1650x1620 | 5.9 |

| QC12Y-6X4000 | 6 | 4000 | 1.5 | 500 | 12 | 7.5 | 4480x1850x1700 | 7.7 |

| QC12Y-6X6000 | 6 | 6000 | 1.5 | 500 | 12 | 11 | 6480x2000x2000 | 15.0 |

| QC12Y-8X2500 | 8 | 2500 | 1.5 | 500 | 18 | 11 | 2990x1700x1700 | 5.0 |

| QC12Y-8X3200 | 8 | 3200 | 1.5 | 500 | 14 | 11 | 3690x1700x1700 | 6.0 |

| QC12Y-8X4000 | 8 | 4000 | 1.5 | 500 | 12 | 11 | 4480x1850x1700 | 8.0 |

| QC12Y-8X6000 | 8 | 6000 | 1.5 | 500 | 12 | 15 | 6480x2000x2000 | 17.0 |

| QC12Y-10X2500 | 10 | 2500 | 2 | 500 | 14 | 15 | 2990x1700x1700 | 8.3 |

| QC12Y-10X3200 | 10 | 3200 | 2 | 500 | 14 | 15 | 3690x1700x1700 | 10.2 |

| QC12Y-10X4000 | 10 | 4000 | 2 | 500 | 12 | 18.5 | 4480x1850x1750 | 11.5 |

| QC12Y-10X6000 | 10 | 6000 | 2 | 500 | 4 | 18.5 | 6450x2450x2350 | 19.0 |

| QC12Y-12X2500 | 12 | 2500 | 2 | 500 | 7 | 18.5 | 3050x2100x2000 | 9.3 |

| QC12Y-12X3200 | 12 | 3200 | 2 | 500 | 7 | 18.5 | 3495x2100x2000 | 11.2 |

| QC12Y-12X4000 | 12 | 4000 | 2 | 500 | 6 | 18.5 | 4450x2150x2000 | 11.0 |

| QC12Y-12X6000 | 12 | 6000 | 2.3 | 500 | 4 | 18.5 | 6450X2350X2650 | 23.0 |

| QC12Y-16X2500 | 16 | 2500 | 2.3 | 500 | 8 | 18.5 | 3145X2127X2135 | 10.4 |

| QC12Y-16X3200 | 16 | 3200 | 2.3 | 500 | 7 | 18.5 | 3600X2127X2135 | 12.0 |

| QC12Y-16X4000 | 16 | 4000 | 2.3 | 500 | 6 | 18.5 | 4350X2200X2150 | 15.5 |

| QC12Y-16X6000 | 16 | 6000 | 3 | 500 | 3~4 | 30 | 6350X2400X2750 | 27.0 |

| QC12Y-20X3200 | 20 | 3200 | 3 | 500 | 3~4 | 30 | 4080X2450X2500 | 15.3 |

| QC12Y-20X4000 | 20 | 4000 | 3 | 500 | 3~4 | 30 | 4350X2450X2500 | 18.5 |

| QC12Y-20X6000 | 20 | 6000 | 3 | 500 | 3~4 | 37 | 6350X2500X2900 | 30.0 |

Details Images

Safety fence

Electric and mechanical interlocking movable safety fence with switch can protect the operator's safety, and can clearly see the shearing situation, which is safe and convenient

Blade clearance adjustment

Rapid adjustment mechanism for rearranging blade clearance, easy operation by hand, realizing stepless adjustment of blade clearance

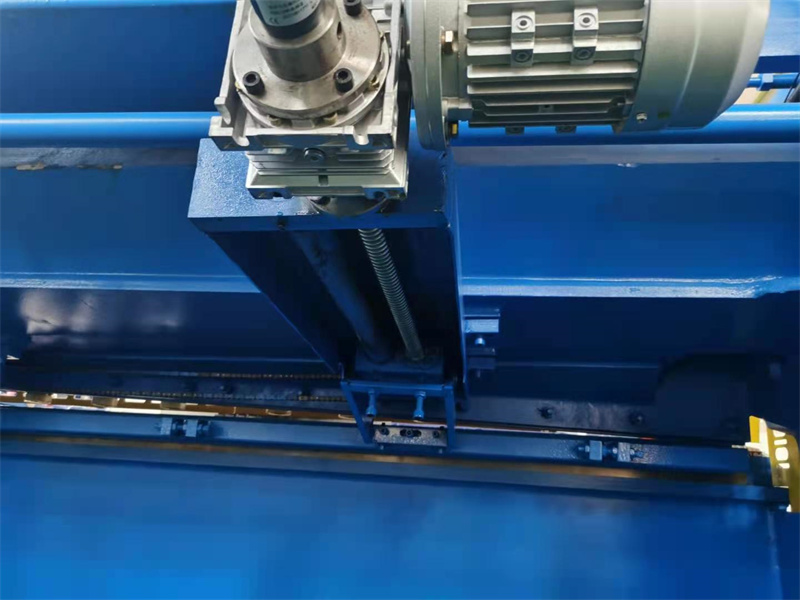

Taiwan HIWIN Ball Screw

High-precision backgauge device, fine ball screw and polished rod structure, high performance motor drive, ensuring the positioning accuracy, unique timing transmission mechanism, reliable and stable

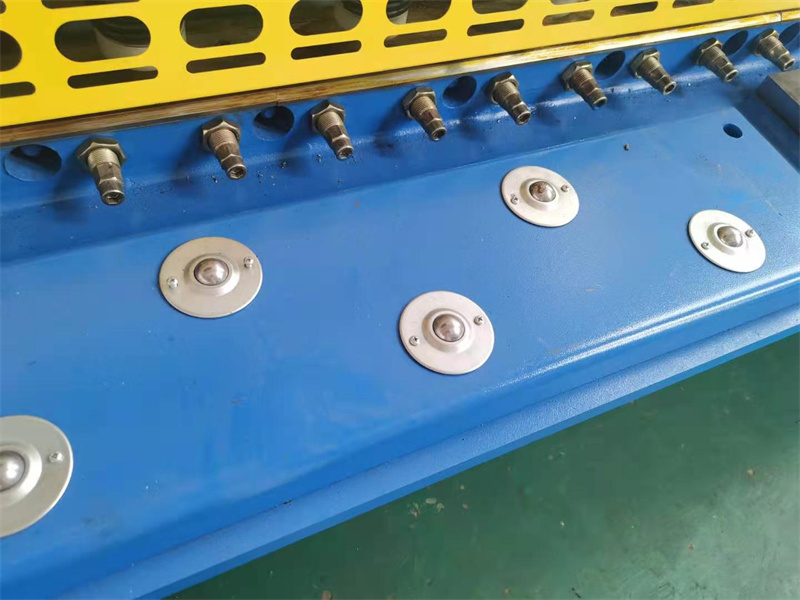

Tower rolling ball

Tower rolling ball, reduces the sheet of material and can reduce scratches

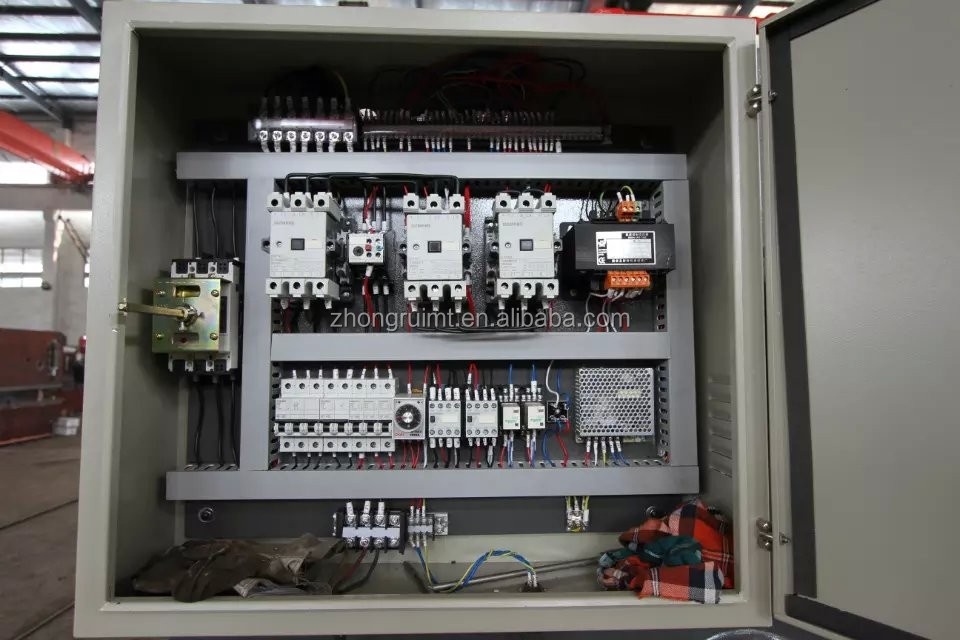

Schneider Electrics of France

High quality electrical parts can work well even if the electricity is not stable and customers can easily get the replacement anywhere in the world

Open Door Power Off

Door of electric cabinet adopts opening door cut off power, ensuring the operational safety

Main motor

It is derived from German brand motor, energy saving and environmental protection, low noise and stable performance.

Germany Bosch-Rexroth Value

Adopt Germany's Bosch Rexroth integrated structure of oil pump and hydraulic valve to ensure the bending accuracy.

Germany EMB Casing Tube

The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the values and affect oil flowing

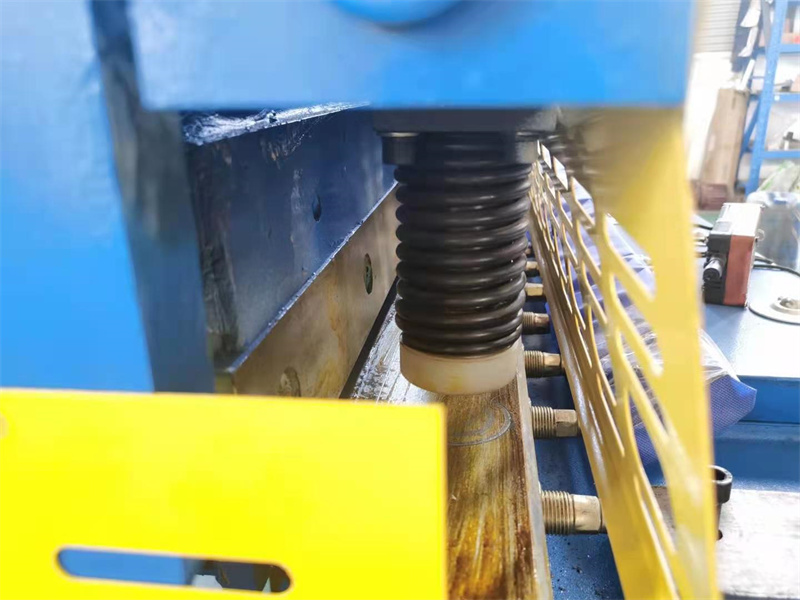

Built-in Spring Pressure Cylinder

Its lower end equipped with special material gasket, separately control the pressure, avoiding aluminium alloy or other softer materials being imprinted.

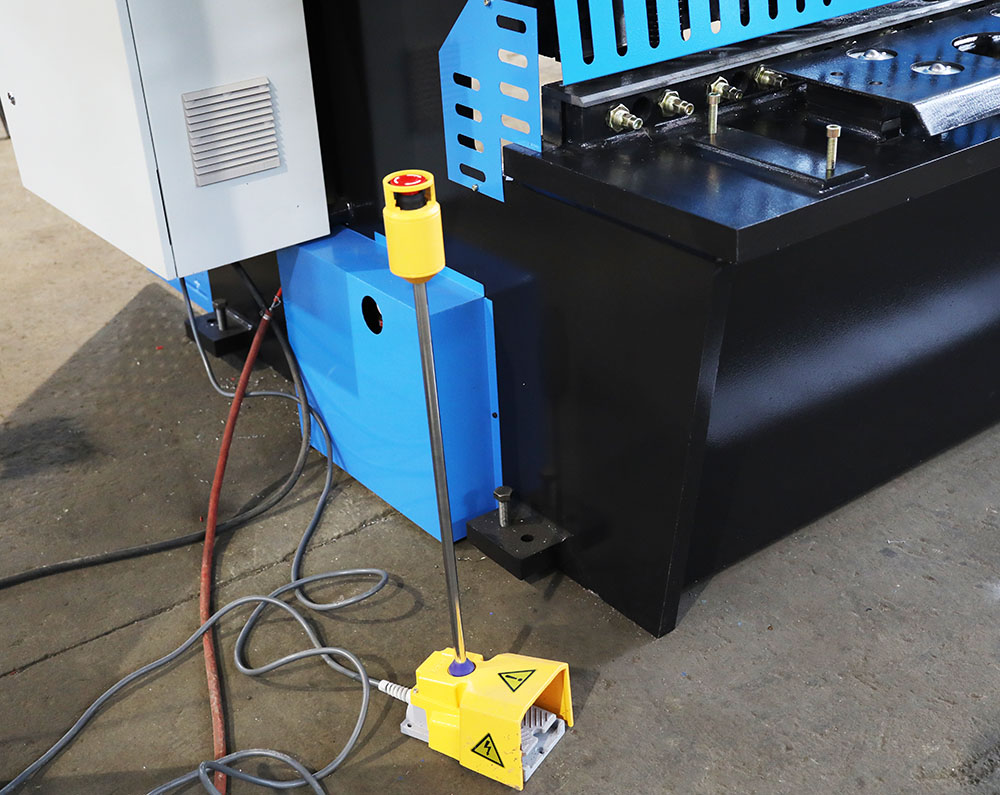

Foot pedal switch

Foot pedal switch South Korea Kacon foot pedal switch with emergency button for safety

Estun E21s NC Control system

● Monochrome LCD Box Panel.

● Integral factor programmable freely

● Automatic positioning control

● Spindle allowance offset

● Internal time relay

● Stock counter

● Backgauge position display, resolution in 0.05mm

Controller

Estun&Delem brand are optional for the NC&CNC hydraulic shearing machine

Company Profile

Anhui zhongrui machine manufacturing co;Ltd was build in 2002 and located in Bowang Special Economical Zone, Anhui province. It was registered RMB 0.21 billion ,occupy 120,000.000 square meter with more than 400 employees and is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experience engineers and designers, and making it is one of the largest manufactures of sheet metal fabricating machinery in China. We are dedicated to the R&D and manufacturing of medium or high -level processing equipment and press lines for punching ,shearing, bending and laser cutting of metal plates.

Zhongrui not only is the AAA level contracts and keep promise in enterprises, but also passes the ISO900 certification and CE certification with years of development and accumulation , we continued to strengthen research and development of new products, introduce the cnc technology which come from Italy and Germany. CNC press brake, cnc fiber laser cutting machine that we produced have achieve a real sense of CNC automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers satisfaction, the company achieved a product with strict control from design, manufacture process, inspection until the whole machine delivery ,installation and service. Zhongrui will keep enterprising in the corporate spirit of "credit, collaboration, pragmatism and innovation" and Sincerely hope to make progress together and jointly create brilliance with friends of all circles

FAQ

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How do I operate this machine?Is training necessary?

A:The machine is mainly controlled by software.Simple, not complicated. Generally speaking, an operator who is not familiar with the press brake can still operate it well.According to customer requirements, we can send technicians to the customer's factory for machine training, or when the customer needs to come to our factory for machine training.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How about your machine quality?

A: We have approved the ISO9001:2008 Quality management system and Europe and American safety standard,including CE,GS,EMS and UL. Zhongrui is a mature brand in China, through our 13 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.

Q: Can you provide customized machine and tool?

A: Yes,we can design and manufacture according to user's specific requirements.