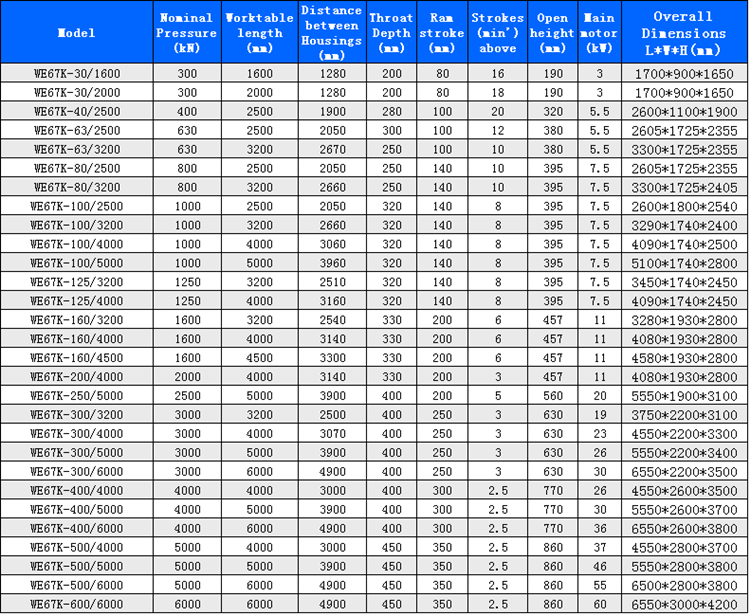

Quick Description

- Slider Stroke (mm): 250 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 400 mm

- Machine Type: Synchronized, Hydraulic CNC Press Brake

- Length of Working Table (mm): 5000 mm

- Width of Working Table (mm): 300 mm

- Dimension: 5100*2300*3600mm

- Condition: New

- Place of Origin: Anhui, China

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Extra Services: End Forming

- Weight (KG): 29000

- Motor Power (kw): 30 kw

- Key Selling Points: Automatic

- Warranty: 2 years

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: None

- Marketing Type: New Product 2020

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 24 months

- Core Components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox

- Name: Hydraulic CNC Press Brake machine we67k-400T/5000 automatic

- Color: Customized metal bending machine

- Type: Metal Bender Tools

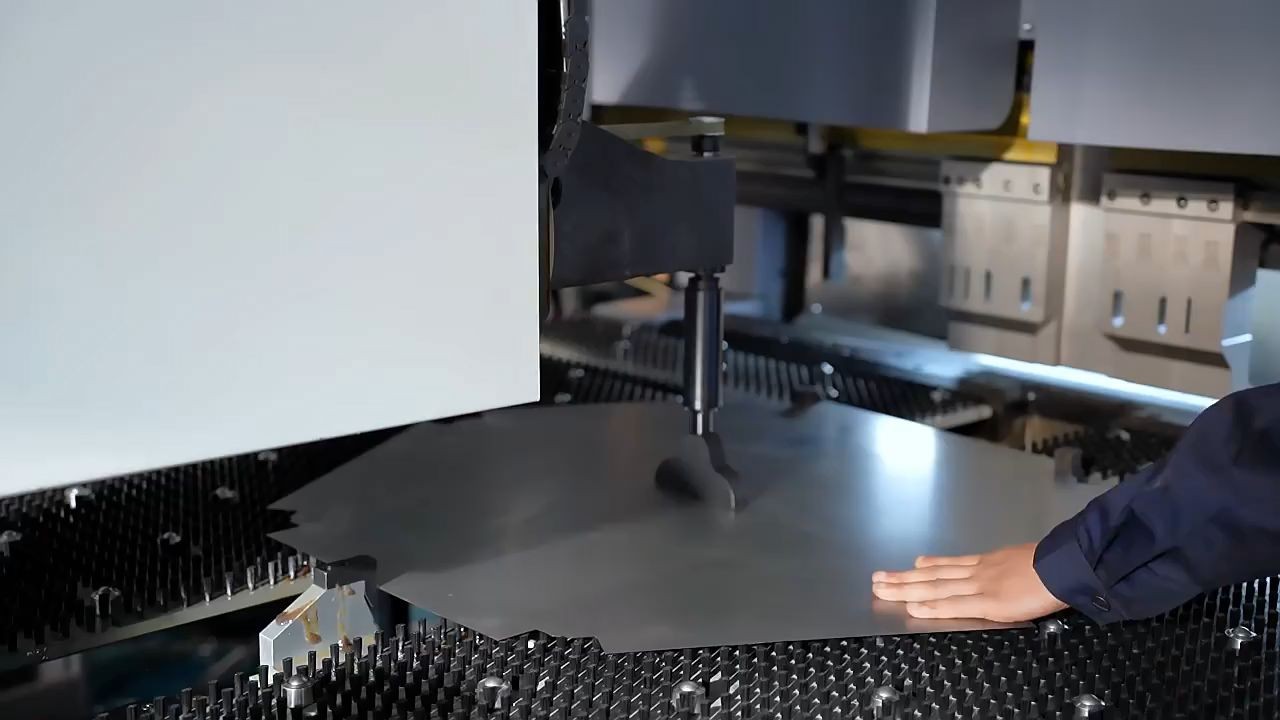

- Usage: Metal Sheet folding Bending

- Model: WC67K-400T/5000 brake press

- Material: Q235A press brake

- Axis: 3 1, 4 1, 5 1, 6 1

- Application: stainless steel bending

- Processing: heavy duty machine

More Details

Machine with crowning (compansation)

Standard cnc press brake with mechanical or hydraulic crowning, to make sure the bending precision

Main features:

1. Holland DELEM DA52/56S CNC system

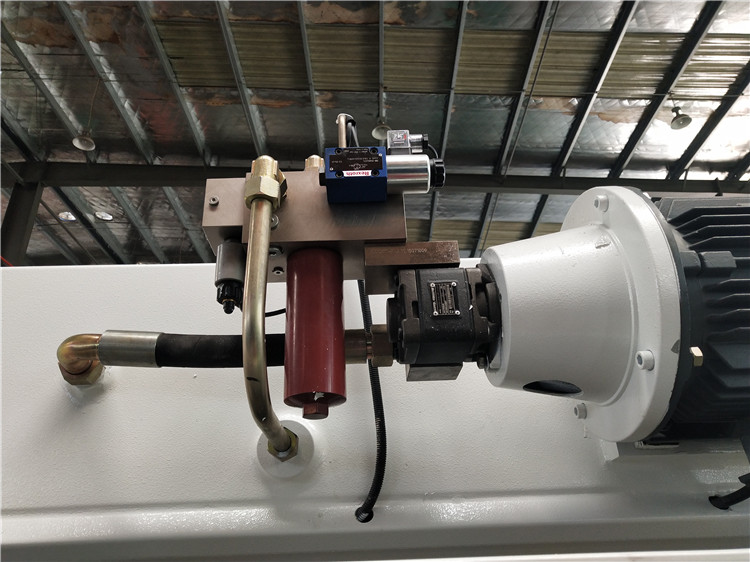

2. Germany Rexroth has the electro-hydraulic servo driven pump control system

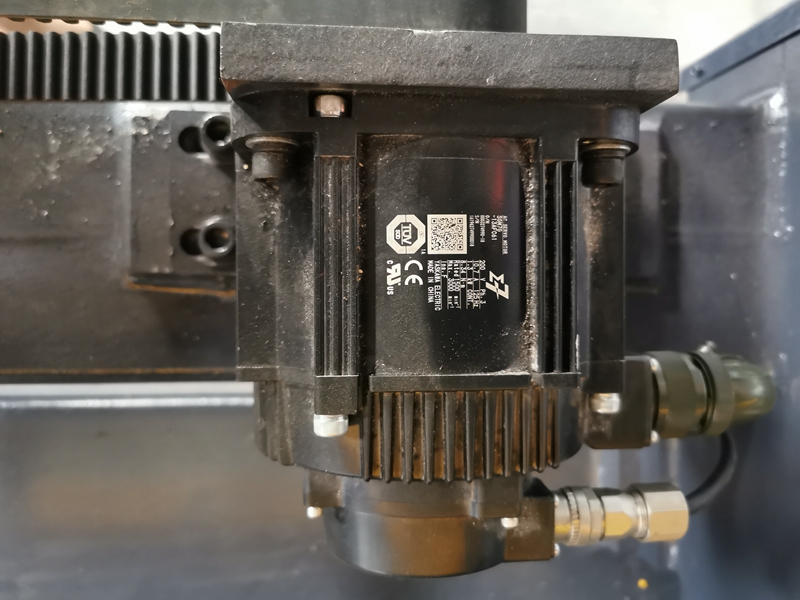

3. Synchronous position on both sides with RSF grating detection •Back gauge with high performance servo motor and ball screw • The WILA mechanical CNC system control under the table the deflection compensation device

4. With a left and a right protective door and rear fender •include standard front support with mobile linear guide track

The machine type and axis of control(Yl -Y2-X-R-W)

1. Professional solutions to meet a variety of applications

2. High-quality components to ensure high reliability

3. Excellent cost performance, fast cost recovery

4. Energy conservasion, a revolutionary breakthrough

Innovative features of the hybrid drive system:

1. Pump control techrology to replace conventional VRLA technology, eliminating throttling losses, no overflow losses, significant energy saving

2. Servo motor in a short time can significantly overload, the actual installed power is only 50% of the theoretical power installation

3. Tank volume decreases by 75% to reduce the usage amount of hydraulic oil

4. Low thermal equilibrium temperature without cooling devices, hydraulic components kfe extension

5. Free, fast, the packing, the r>ex( state return decreased noise, improve the worrvg environment

6. Servo motor brake faster than ihe average, an emergency pressure, flow rate cut soon

7. Reduce oil particles from sensitive NS7 grade level dropped NS9 alves

8. Panel based controller with optional housing

Detailed Image

High quality HIWIN linear guide ball screw--to improve the bending precision of press brake

bending die

ESA 625 controller

Servo motor

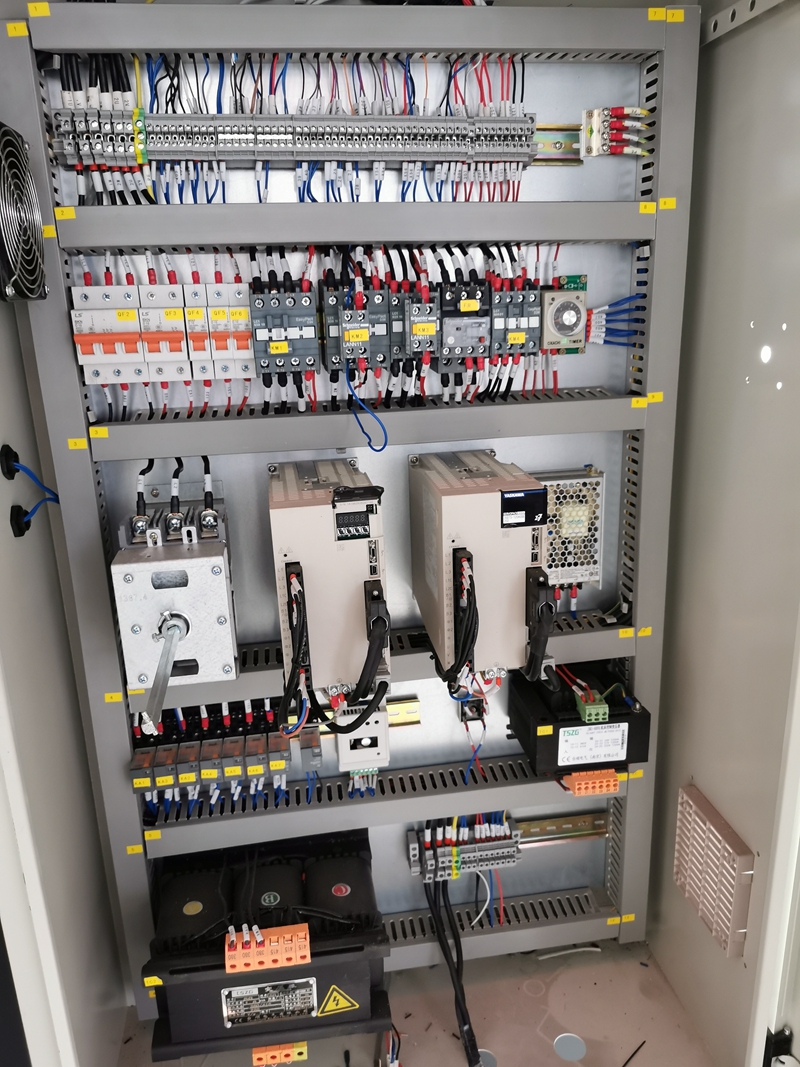

Electric box

Hydraulic crowning

Oil cooling fans for optional

Italy laser light curtain protection-optional

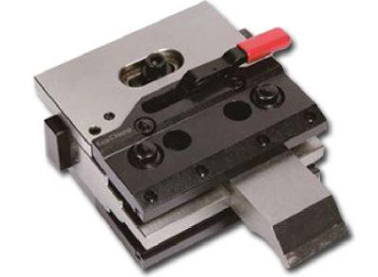

TYOKKO fast change clamp

AMADA fast change clamp