Quick Description

- Slider Stroke (mm): 200 mm

- Automatic Level: Fully Automatic

- Throat Depth (mm): 250 mm

- Machine Type: Synchronized

- Length of Working Table (mm): 2500mm

- Width of Working Table (mm): 180 mm

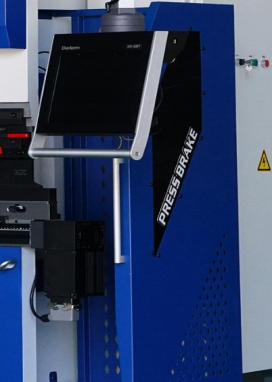

- Condition: New

- Place of Origin: Anhui, China

- Brand Name: RAYMAX/BEILIN

- Material / Metal Processed: Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

- Automation: Automatic

- Weight (KG): 5800

- Motor Power (kw): 5.5 kw

- Key Selling Points: Multifunctional

- Warranty: 2 years

- Applicable Industries: Hotels, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Retail, Printing Shops, Energy & Mining

- Showroom Location: United States, Spain, Thailand

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Free spare parts

- After Warranty Service: Video technical support

- Local Service Location: United States

- Nominal Pressure (kN): 800 kN

- Certification: CE

More Details

Products Description

* Overall welded and processed structure

* Dual cylinders synchronous controlled by electro-hydraulic servo vale, ensure the highest controlling precision, bending accuracy and repositioning accuracy are also reach the highest level

* Backgauge mechanism can control several backgauge axes

* Hydraulic compensation mechanism helps to prevent the deformed slider from affecting the quality of the workpiece, and the compensation mechanism is adjusted automatically by the CNC controller which is convenient and accuracy

* WF67K Series machines redesigned based on users preferences to become a unique machine with its individual electronic and mechanical features.

* WF67K Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level with its user friendly CNC controller and low cost hydraulic maintenance.

* New WF67K is exactly what you need for your production where complicated, sensitive, single or multiple bends on high speed are paramount.

* High quality and repetitive bending is obtained by using synchronized cylinders and valves.

* Automatic utilization of all axes on startup.

* Rigid upper beam runs on 8-point bearings with bending precision of 0,01 mm.

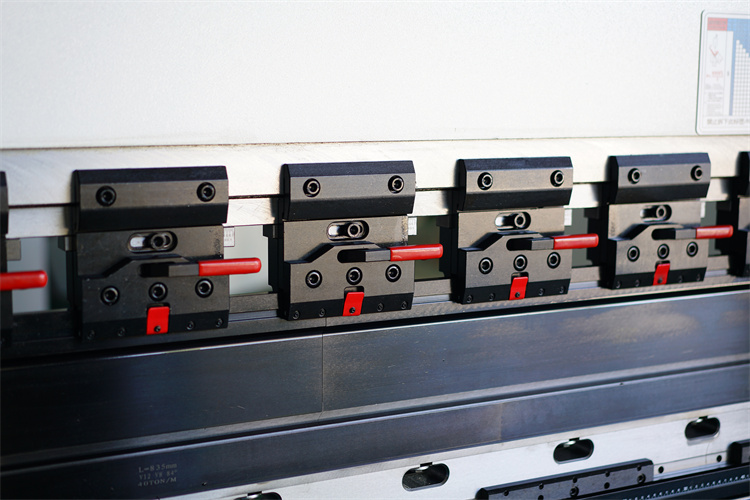

* Well-known top and bottom tool brands are long lasting hardened and provide precise bending.

* The machines are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel using the latest Technology.

Feature

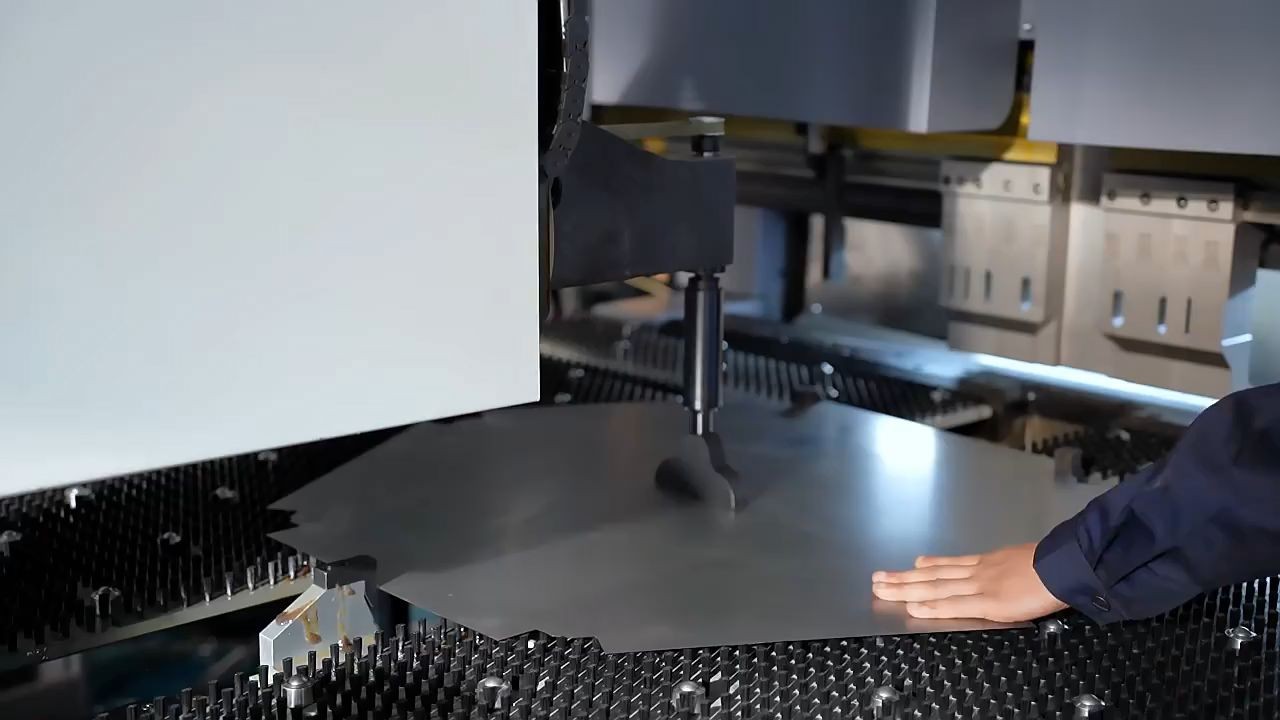

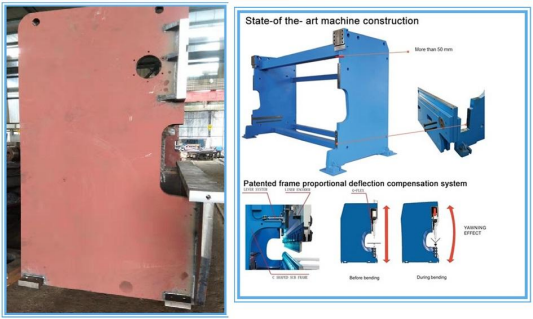

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

4. Torsion axis synchronization for slide synchronous mechanism.

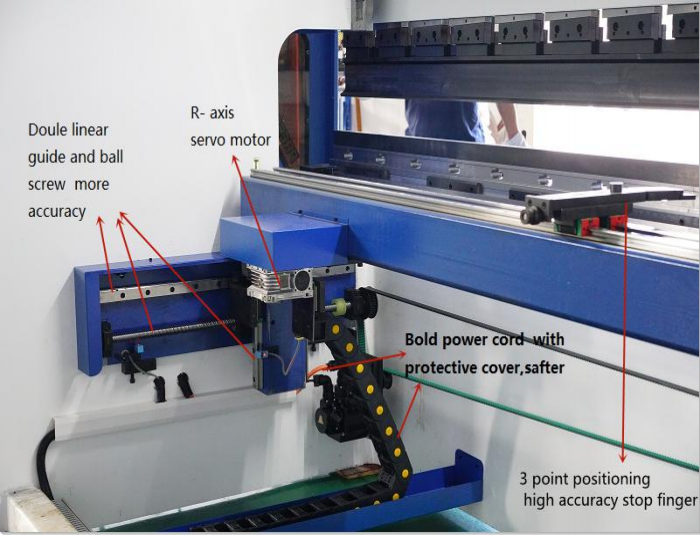

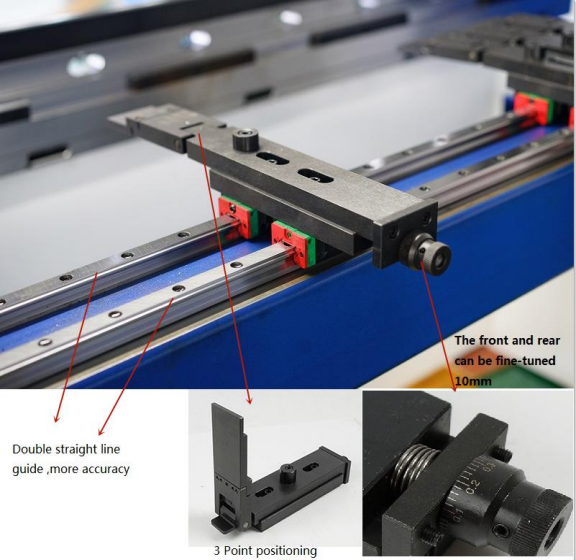

5. The stroke of cylinder ( Y1,Y2) and back gauge (X,Y,Z )are computer controlled .The back gauge adopt ball screw and rolling guideway , ensuring a high accuracy of repetition

6. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

7. The CNC system adopts frequency conversion control technology, with multi-step programming function, simple and easy to operate.

8. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

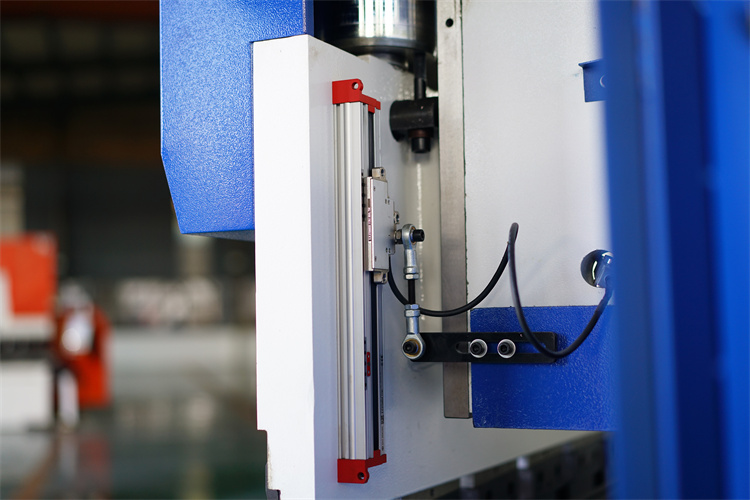

10. Electronic- hydraulic proportional servos are synchronized and capable of the control of random point within the stroke, with an accuracy of reception of ±0.01 mm and parallelism of 0.02mm .

Standard equipment

Safety Standards(2006/42/EC):

1. EN 12622:2009 A1:2013

2. EN ISO 12100:2010

3. EN 60204-1:2006 A1:2009

4. Front finger Protection(Safety light curtain)

5. South Korea Kacon Foot Switch(Level 4 of safety)

6. Back metal safe fence with CE standard

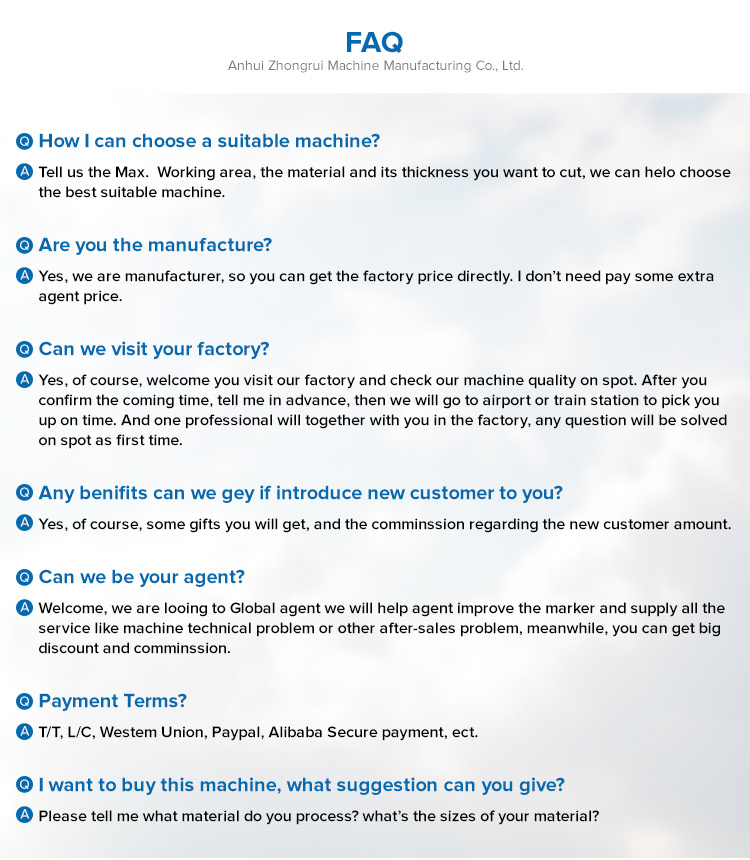

Details Images

A large floor milling and boring machine is used to process the frame of the bending machine

The whole machine is in a welded sheet structure, with internal tension eliminated by vibration aging technology, high strength and good rigidity of the machine. The long service life of the machine is ensured.

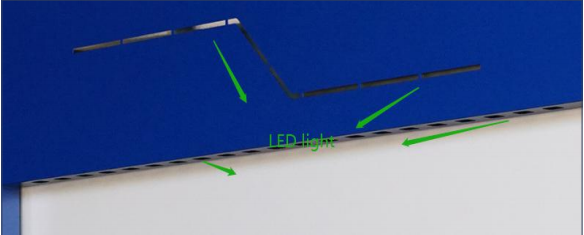

LED light

LED light, it is easier and safer when the environment is dark for the operator

Grating Ruler

Measuring step 5 um connection rod connection large mounting tolerances

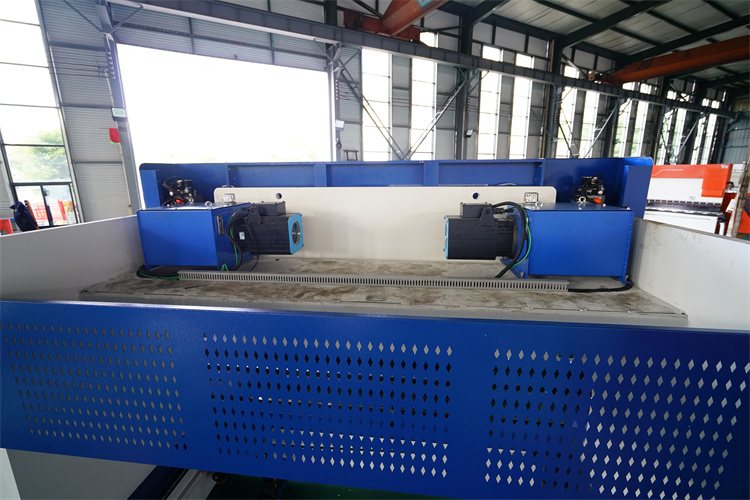

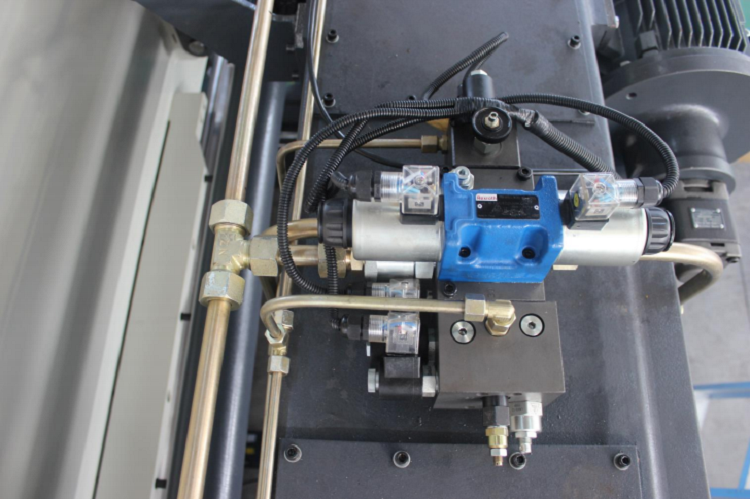

BOSCH-REXROTH Hydraulic system

- BOSCH-REXROTH Hydraulic system with overload overflow safety protection

- The machine can work continuously under rated load

- Hydraulic system decreased the pipe connections, oil leakage, and increased the stability and overall beautifies

- High-pressure clamp tubing connection, high-pressure non-oil, easy to maintain

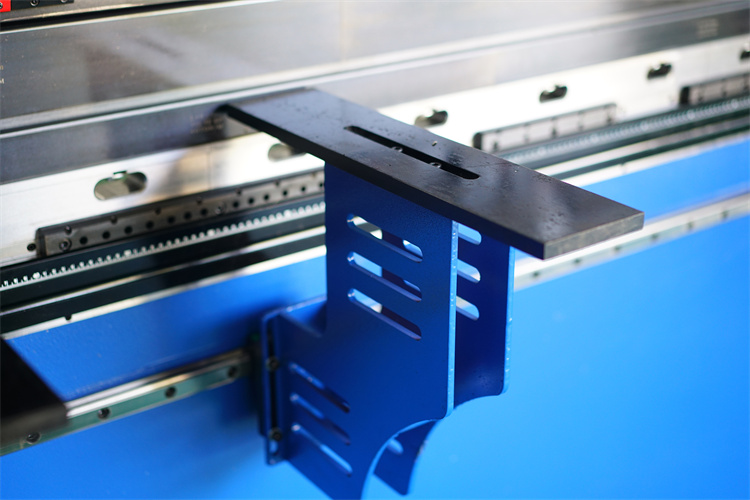

Backgauge

- The backgauge, it is made of high-strength aluminum alloy material, driven by servo motors,and uses ball rods and linear guide rails, with good positioning accuracy.

- Full envelope design free of maintenance

France Schneider Electrics

Adopting France Schneider electric to ensures the machine stability, using Estun servo drive and control X-axis to ensure the positioning accuracy of X-axis, and the speed of X-axis are adjustable.

Servo drive

Stable performance. It can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object

Optional servo drive: YASKAWA,Japan

Double structure front arm

Double structure front arm is higher rigidity, superior carrying capacity. It can be adjusted up and down or move along the work bench from side to side

Italy DSP Laser protection

Karcon Pedal switch with emergency button

Protective fence

Product Parameters

| Model | Column distance | Throat depth | Opening height | Main motor | Weight |

| 63T/2500 | 1900mm | 250mm | 360mm | 5.5KW | 3600KGS |

| 63T/3200 | 2600mm | 220mm | 360mm | 5.5KW | 4200KGS |

| 80T/2500 | 1900mm | 320mm | 380mm | 7.5KW | 4100KGS |

| 80T/3200 | 2600mm | 320mm | 380mm | 7.5KW | 4800KGS |

| 80T/4000 | 3100mm | 320mm | 380mm | 7.5KW | 5300KGS |

| 100T/2500 | 1900mm | 320mm | 380mm | 7.5KW | 5100KGS |

| 100T/3200 | 2600mm | 320mm | 380mm | 7.5KW | 5900KGS |

| 100T/4000 | 3100mm | 320mm | 380mm | 7.5KW | 6800KGS |

| 125T/3200 | 2600mm | 320mm | 400mm | 7.5KW | 6200KGS |

| 125T/4000 | 3100mm | 320mm | 400mm | 7.5KW | 7200KGS |

| 160T/3200 | 2600mm | 320mm | 450mm | 11KW | 9200KGS |

| 160T/4000 | 3100mm | 320mm | 450mm | 11KW | 10500KGS |

| 200T/3200 | 2600mm | 320mm | 450mm | 11KW | 10500KGS |

| 200T/5000 | 4000mm | 320mm | 450mm | 11KW | 13000KGS |

| 250T/3200 | 2600mm | 350mm | 450mm | 11KW | 15000KGS |

| 250T/4000 | 3100mm | 350mm | 550mm | 18.5KW | 18000KGS |

| 300T/4000 | 3100mm | 350mm | 550mm | 22KW | 22000KGS |

| 400T/4000 | 3100mm | 350mm | 550mm | 30KW | 23000KGS |

| 400T/6000 | 5000mm | 350mm | 550mm | 30KW | 29000KGS |

Company Profile

Anhui zhongrui machine manufacturing Co;Ltd was build in 2002. It is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experienced engineers and designers, which makes it be a well-known brand of sheet metal fabricating machinery in China.

We are a modernized machine tool factory which is dedicated to the development, production and sales of sheet metal equipment with history over than 20 years. The factory mainly specializes in press brake, shearing machine, hydraulic press machine, fiber laser cutting machine and punching machine. Professionally provide complete sets of metal sheet and profile processing machinery for automobiles, ships, railways, aviation, electric power, petrochemicals, light industry and other industries; products are sold all over the country and exported to Southeast Asia, Middle East, Western European, South America and other regions.

We have passed the I S O 9 0 0 1 certification and C E certification. We continued to strengthen research and development of new products, introduce the c n c technology which comes from Italy and Germany. C N C press brake, C N C fiber laser cutting machine that we produced have achieved a real sense of C N C automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers’ satisfaction, we have realized strict control of products from design, manufacturing process, inspection to complete machine delivery, installation and service.