Quick Description

- Max. Cutting Width (mm): 4000

- Max. Cutting Thickness (mm): 16 mm

- Automatic Level: Fully Automatic

- Blade Length (mm): 4100 mm

- Throat Depth (mm): 300 mm

- Condition: New

- Brand Name: Beilin/RAYMAX

- Power (kW): 18.5 kW

- Weight (KG): 14000 KG

- Place of Origin: Anhui, China

- Voltage: Customer's Requirment

- Warranty: 2 years

- Key Selling Points: High Safety Level

- Applicable Industries: Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Retail

- Showroom Location: United States

- Marketing Type: Other

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- Type: shear machine

- After-sales Service Provided: Engineers available to service machinery overseas

- Keyword: shearing machine

- Material strength: ≤450 KN

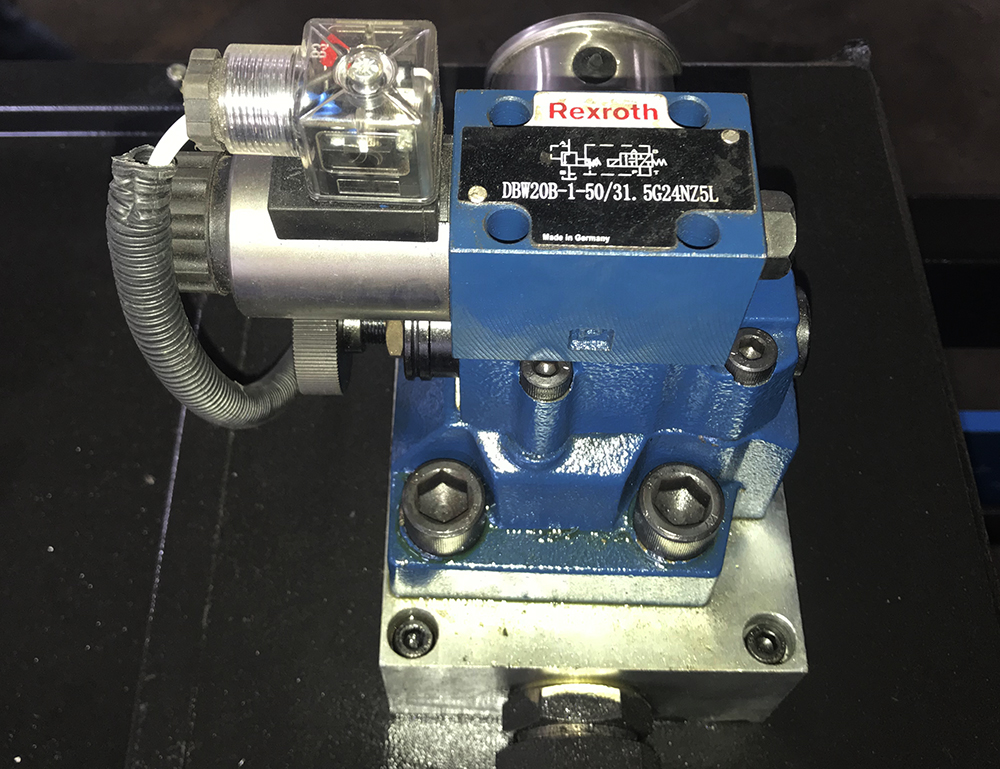

- Hydraulic System: Rexroth Germany

- Stoper adjust range: 20-500 mm

- Color: Optinal

More Details

Product Description

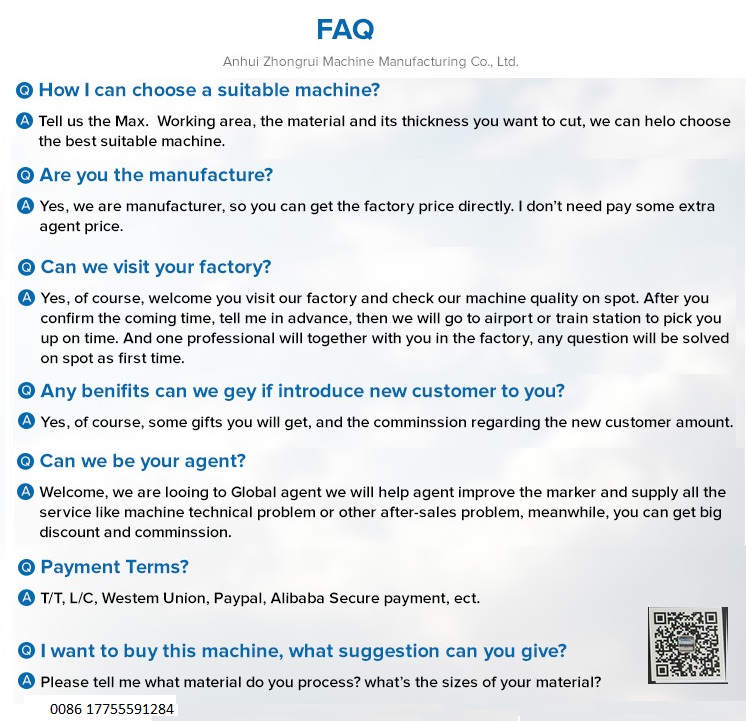

QC11Y 16X4000 Guillotine shearing machine stainless steel metal sheet iron plate sheet cutting machine

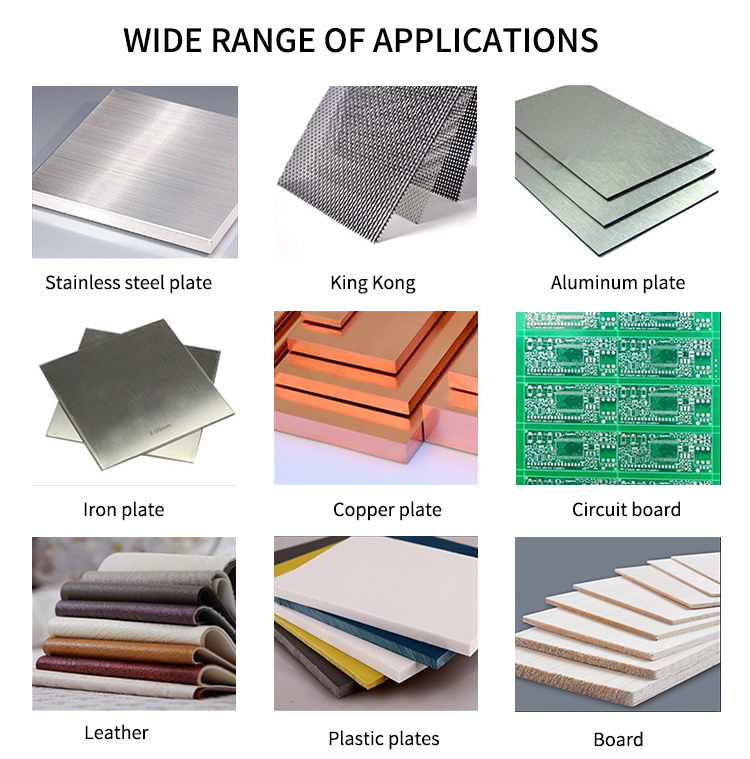

The hydraulic guillotine shearing machine is suitable for working over sheet metals and plate metals. They are intended for cutting various types of table sheet materials made of steel, stainless steel, aluminum, copper, cardboard and etc. The guillotine sheet metal shear is featured with excellent functional aspects that make it a top preference in many metalworking industries. Zhongrui, a professional guillotine shearing machine manufacturer in China, provides high productive hydraulic guillotine shearing machine with rock-solid hydraulic, accurate ball screw back gauge, user-friendly CNC Controller.

1. The machine adopts full steel welding structure, vibration eliminate stress, has the very good rigidity and stability .

2. Hydraulic Guillotine Shearing machine adopt ball screw, linear guide and servo motor to drive the back gauge with high positioning accuracy

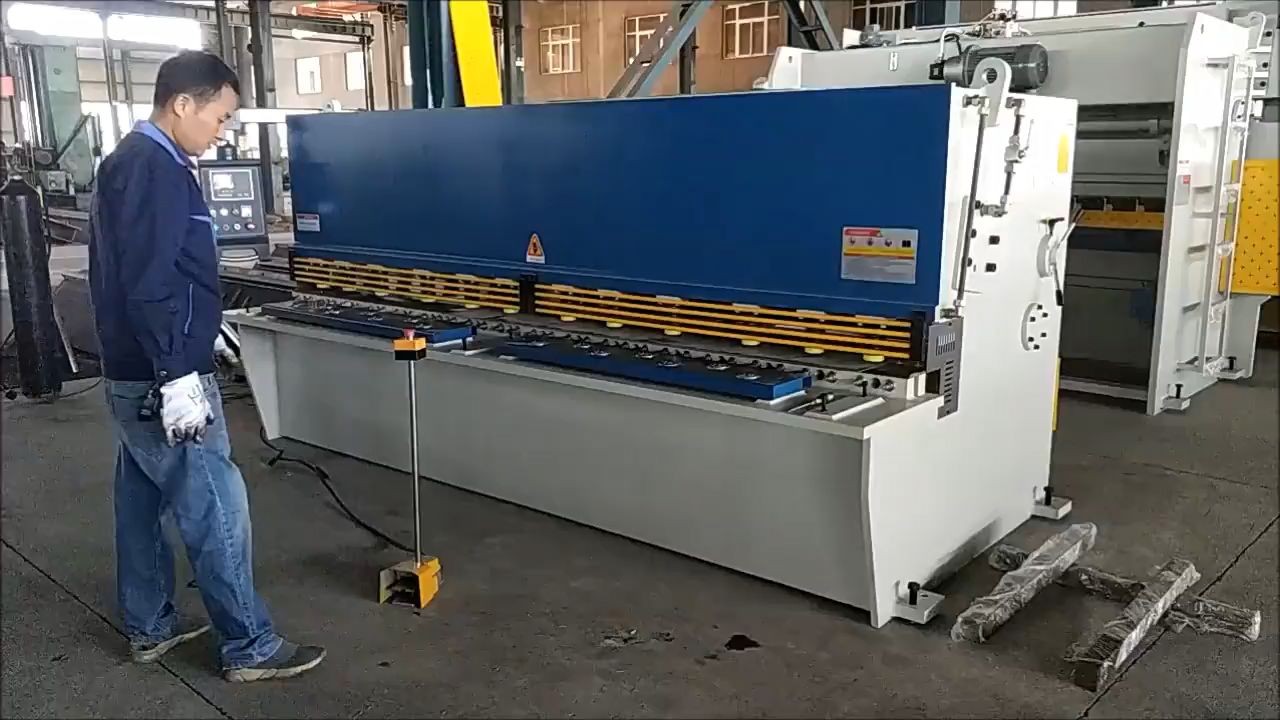

3. Rapidly,accurately and conveniently adjusting the blade clearance by motor.

4. Integrated steel welded structure,eliminate stress by vibration,with good rigidity.

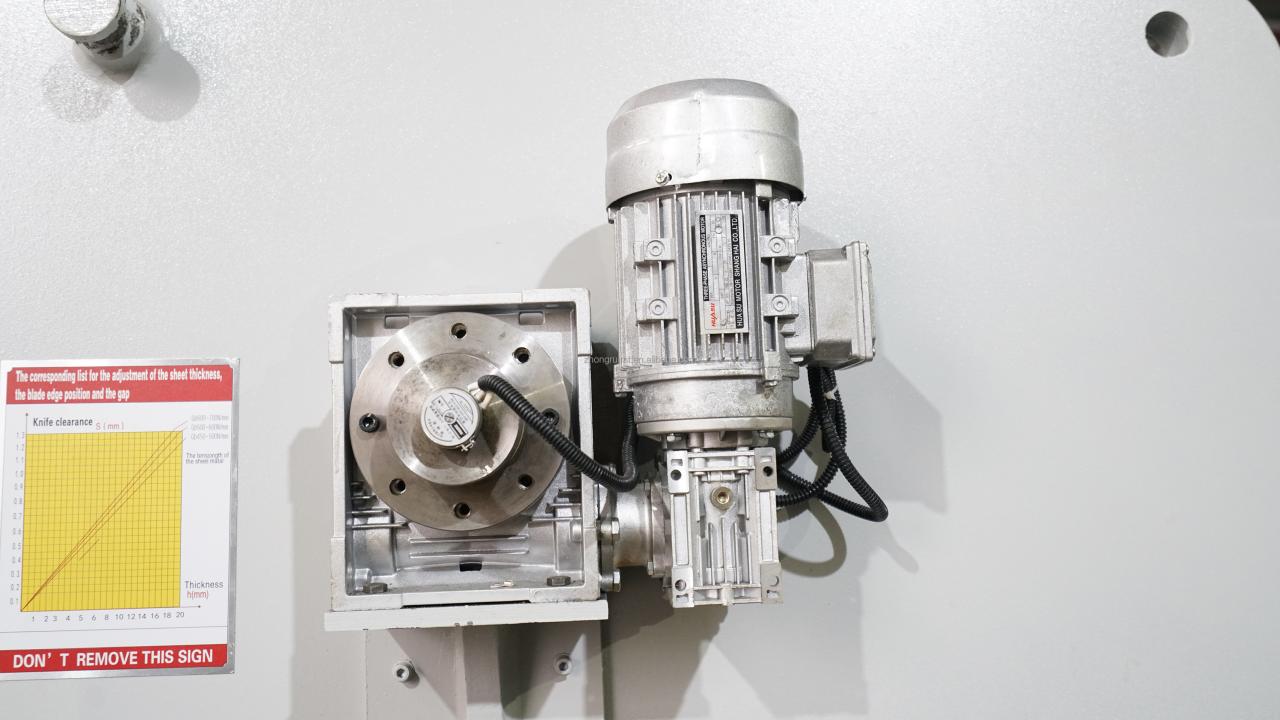

5. Adopt the advanced hydraulic integrated valve block which is in compact structure and will reduce piping connections, and improves system reliability and maintainability.

6. Accumulator return smooth and rapid

Manual/automatic adjustment of blade clearance (depend on the controller), accurate, rapid and convenient

Standard equipment

●ELGO P40T CNC control System

●Servo motor controlled back gauge

●Blade gap adjustment,Cutting Angle & Back gauge by P40T CNC System

●HIWIN Ball screws & Polished rod with 0,01 mm accuracy.

●Squaring Arm and Front Support Arms

●Germany Bosch-Rexroth Hydraulic

●Germany EMB Tubing connector

●Germany Siemens Main Motor

●Telemecanique/Schneider Electrics

●Hydraulic & Electrical overload protection

●Cutting Line Illumination and wire for shadow line cutting

●Top blade with two cutting edges and bottom blade with four cutting edges. (6CrW2Si)

Detailed Images

Safety fence

Electric and mechanical interlocking movable safety fence with switch can protect the operator's safety, and can clearly see the shearing situation, which is safe and convenient

Servo motor

It is derived from German brand motor, energy saving and environmental protection, low noise and stable performance.

Tower rolling ball

Rolling steel ball of workbench can reduce friction, protect the workpiece surface; delicate design is convenient for cutting petty materials by hand

Schneider Electrics of France

High quality electrical parts can work well even if the electricity is not stable and customers can easily get the replacement anywhere in the world

Germany EMB Casing Tube

The EMB Casing Tube and connectors effectively reduce the adds against welding slag jamming the values and affect oil flowing

Backgauge

High precise backgauge, equipped with HIWIN ball screw and polished rod structure

Pressing Mechanism

Shearing machine is equipped with plate pressing mechanism. The pressing head presses down to compress the plate when cutting plate.

Blade clearance adjustment

Rapid adjustment mechanism for rearranging blade clearance, easy operation by hand, realizing stepless adjustment of blade clearance

Hydraulic system

*Hydraulic system is from Bosch-Rexroth, Germany.

*Adopt integrated hydraulic control system, more reliable and easy for maintenance.

*Reduced noise: the particular installation choices allow to obtain especially moderate noise levels both on machines of average capacity

*Hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid

*Overload overflow protection is outfitted to hydraulic system, which can assure no leakage, and the oil level can be read or seen directly.

*The hydraulic system is made in compliance with current regulations (Directive 98/37 EC).

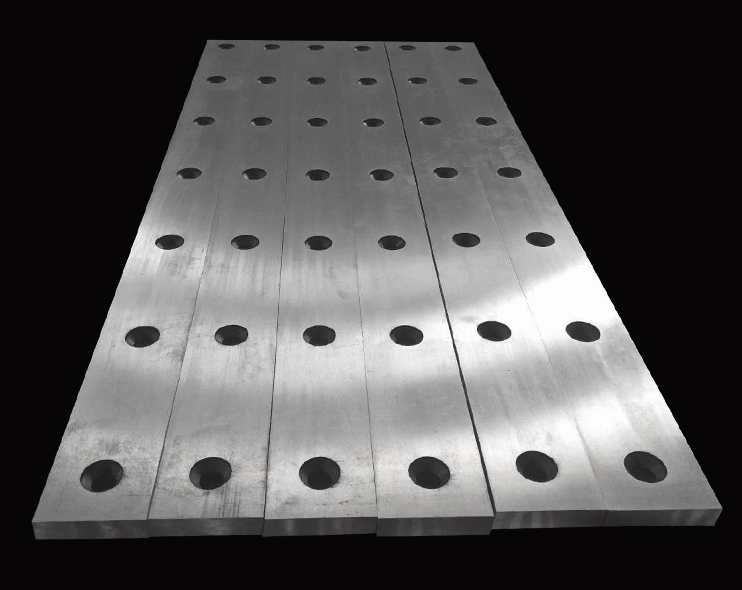

High quality blade

The blade of cnc hydraulic shearing machine increased blade durability and reduced retooling time.

Higher precision available,anti vibration and small thermal deformation.

Excellent cutting quality,stable and reliable cutting performance.

Assuring you the maximum performance and the best maintenance of all knives.

Optional controller

ELGO P40T

•GERMANY ELGO P40T NC Control Unit:

•Large Color 7” LCD Touch Screen

•Back / front gauge control

•Auto Setting of Blade Clearance

•Auto Setting of Rake Angle

•Stroke length limitation

•Manual movement of all axes

•USB Port for user USB Memory

•User Program and Steps: Unlimited

•Sheet thickness measurement

•RTS, Return to Sender function

CT8

* 7" monochrome LCD Touch screen

* 3 regular materials are set by default in the system: steel, stainless steel, aluminum. Users can add new materials by themselves

* numerical programming

* Internal backup function : save production and parameters

* RF-link wireless radio frequency data communication allow backup and restoring operations

* On-line help and interactive warning pop-ups

* Angle and back gauge correction.

* Easy Operating

DAC 360T

* Panel based housing

* Bright LCD screen

* Back / front gauge control

* Retract function

* Cutting angle and gap control

* Stroke length limitation

* Manual movement of all axes

* Force control

* Sheet thickness measurement

* Return to Sender function

* Second and third servo axis (DAC-362T)

* Sheet support

E21S

● Monochrome LCD Box Panel.

● Integral factor programmable freely

● Automatic positioning control

● Spindle allowance offset

● Internal time relay

● Stock counter

● Backgauge position display, resolution in 0.05mm

Application

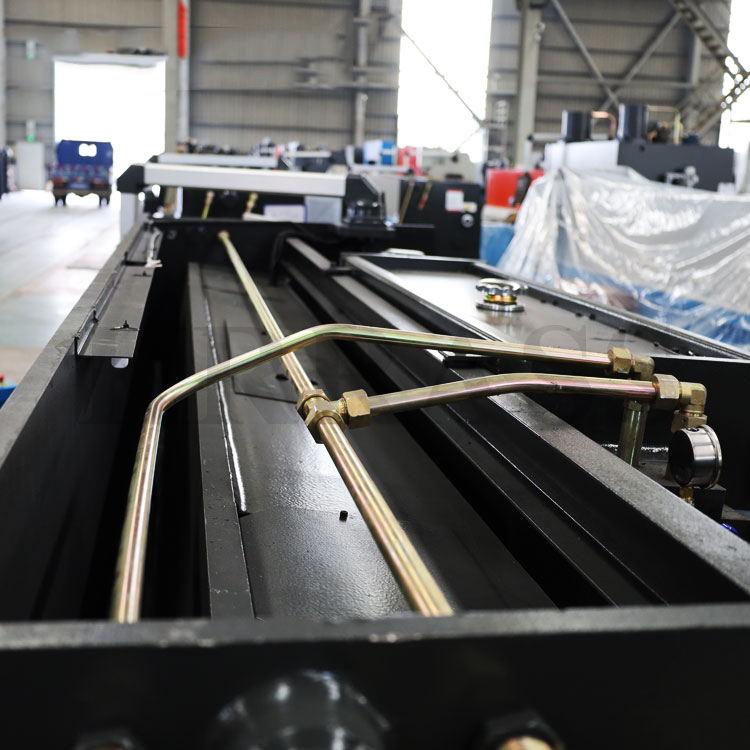

Parameter

| Model | Cutting thickness (mm) | Cutting length (mm) | Cutting Angel (°) | Stopper Adjust Range (mm) | Stroke time (min-1) | Motor (KW) | Dimension(mm) | Weight(t) |

| QC11Y-6X2500 | 6 | 2500 | 0.5~1.5 | 500 | 20 | 7.5 | 2850X1800X1950 | 4 |

| QC11Y-6X3200 | 6 | 3200 | 0.5~1.5 | 500 | 16 | 7.5 | 3450X1850X2000 | 5.2 |

| QC11Y-6X4000 | 6 | 4000 | 0.5~1.5 | 500 | 12 | 7.5 | 44550X1850X2000 | 7 |

| QC11Y-6X6000 | 6 | 6000 | 0.5~1.5 | 500 | 10 | 15 | 6940X2200X2450 | 11.5 |

| QC11Y-8X2500 | 8 | 2500 | 0.5~1.5 | 500 | 18 | 11 | 2860X1850X2150 | 5 |

| QC11Y-8X3200 | 8 | 3200 | 0.5~1.5 | 500 | 14 | 11 | 3460X1850X2150 | 6.2 |

| QC11Y-8X4000 | 8 | 4000 | 0.5~2 | 500 | 12 | 11 | 4550X1750X1950 | 8 |

| QC11Y-8X6000 | 8 | 6000 | 0.5~2 | 500 | 10 | 15 | 6940X2250X2550 | 14 |

| QC11Y-10X2500 | 10 | 2500 | 0.5~2 | 500 | 15 | 15 | 2950X1850X2050 | 7 |

| QC11Y-10X3200 | 10 | 3200 | 0.5~2 | 500 | 13 | 15 | 3650X1850X2050 | 8.3 |

| QC11Y-10X4000 | 10 | 4000 | 0.5~2 | 500 | 12 | 18.5 | 4550X2050X2150 | 9 |

| QC11Y-10X6000 | 10 | 6000 | 0.5~2 | 600 | 10 | 18.5 | 6850X2550X2650 | 17 |

| QC11Y-13X2500 | 13 | 2500 | 0.5~2 | 600 | 14 | 15 | 3050X2050X2150 | 8 |

| QC11Y-13X3200 | 13 | 3200 | 0.5~2 | 600 | 13 | 15 | 3650X2050X2150 | 9 |

| QC11Y-13X4000 | 13 | 4000 | 0.5~2 | 600 | 10 | 18.5 | 4550X2050X2150 | 10 |

| QC11Y-13X6000 | 13 | 6000 | 0.5~2 | 600 | 8 | 22 | 6850X2550X2650 | 16 |

| QC11Y-16X2500 | 16 | 2500 | 0.5~2 | 600 | 12 | 18.5 | 2850X2150X2350 | 9 |

| QC11Y-16X3200 | 16 | 3200 | 0.5~2 | 600 | 10 | 18.5 | 3650X2150X2350 | 10.6 |

| QC11Y-16X4000 | 16 | 4000 | 0.5~2 | 600 | 9 | 18.5 | 4350X2250X2450 | 14 |

| QC11Y-16X6000 | 16 | 6000 | 0.5~2 | 600 | 8 | 30 | 6850X2550X2750 | 25 |

| QC11Y-20X3200 | 20 | 3200 | 0.5~3 | 600 | 10 | 30 | 3550X2350X2550 | 18 |

| QC11Y-20X4000 | 20 | 4000 | 0.5~3 | 600 | 8 | 30 | 4540X2500X2950 | 22 |

| QC11Y-20X6000 | 20 | 6000 | 0.5~3 | 600 | 8 | 30 | 6850X2650X2950 | 28 |

Company Introduction

Anhui zhongrui machine manufacturing co;Ltd was build in 2002 and located in Bowang Special Economical Zone, Anhui province. Itwas registered RMB 0.21 billion ,occupy 120,000.000 square meter with more than 400 employees and is composed of highly trained and qualified machine operators and assembly technicians supported by staff of experience engineers and designers, and making it is one of the largest manufactures of sheet metal fabricating machinery in China. We are dedicated to the R&D and manufacturing of medium or high -level processing equipments and press lines for punching ,shearing, bending and laser cutting of metal plates.

Zhongrui not only is the AAA level contracts and keep promise in enterprises, but also passes the ISO9001 certification and CEcertification With years of development and accumulation , we continued to strengthen research and development of new products ,introduce the cnc technology which come from Italy and Germany. CNC press brake ,cnc fiber laser cutting machine that we produced have achieve a real sense of CNC automatic control and improve the productivity greatly. To control the quality strictly and to ensure the customers satisfaction, the company achieved a product with strict control from design, manufacture process, inspection until the whole machine delivery ,installation and service. Zhongrui will keep enterprising in the corporate spirit of "credit, collaboration, pragmatism and innovation" and Sincerely hope to make progress together and jointly create brilliance with friends of all circles